‘Driving circular transformation’ – under this motto, Qlar is promoting sustainable and digitalised processes. The expert of mission-critical applications for bulk materials will be demonstrating at K 2025, what this looks like in concrete terms. The company relies on innovative hardware in combination with intelligent, digital integration to maximise productivity, minimise downtime and sustainably optimise the material flow at every stage of recycling and processing. Qlar thus supports its customers to achieve the ambitious goals of climate neutrality by 2050.

Intelligent process control

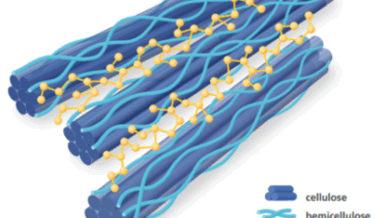

A highlight of the trade fair presentation is the SIMPLEX FB, a gravimetric stainless-steel feeder with a high feed rate that can be used to dose a variety of materials – from glass and carbon fibres to plastic flakes, cellulose and other new or recycled materials. ‘The SIMPLEX FB shows its particular strengths when handling post-consumer material,’ says Frederik Hanß, Head of Sales Chemicals & Performance Materials EMEA at Qlar. ‘Thanks to the bottom-driven agitator and the low centre of gravity, even regrinds or plastic flakes that are difficult to dose can be processed.’ The integrated sensor system allows data to be collected and transmitted in real time. The intelligent system enables fill level measurement and bridge detection as well as moisture measurement of the material. Possible blockages in the discharge are recognised at an early stage – jammed material can be removed in time before a major backlog occurs. Depending on the speed and filling level, optimum operating values for different materials can be determined and saved. Ultimately, the digitalisation of the dispensing processes creates a perfect basis for long-term process optimisation.

Visitors to the K 2025 can discover how intelligent, networked data increases operational reliability and leads to efficiency gains via an interactive touch display at Qlar’s booth 10G46. The expert for process-critical bulk solids applications is looking forward to deepening the dialogue with customers and industry experts and actively shaping the future of the circular economy.

More information at www.qlar.com/meet-qlar-at-k-2025