Advanced Volumetric Feeding Solutions

Volumetric feeding is a cornerstone of many industrial processes where bulk materials must be delivered in precise quantities over time. This technique offers consistent material flow rates vital for downstream processing and quality control. WAMGROUP’s volumetric feeders leverage decades of expertise to provide reliable, flexible, and easy-to-maintain solutions that meet diverse application needs.

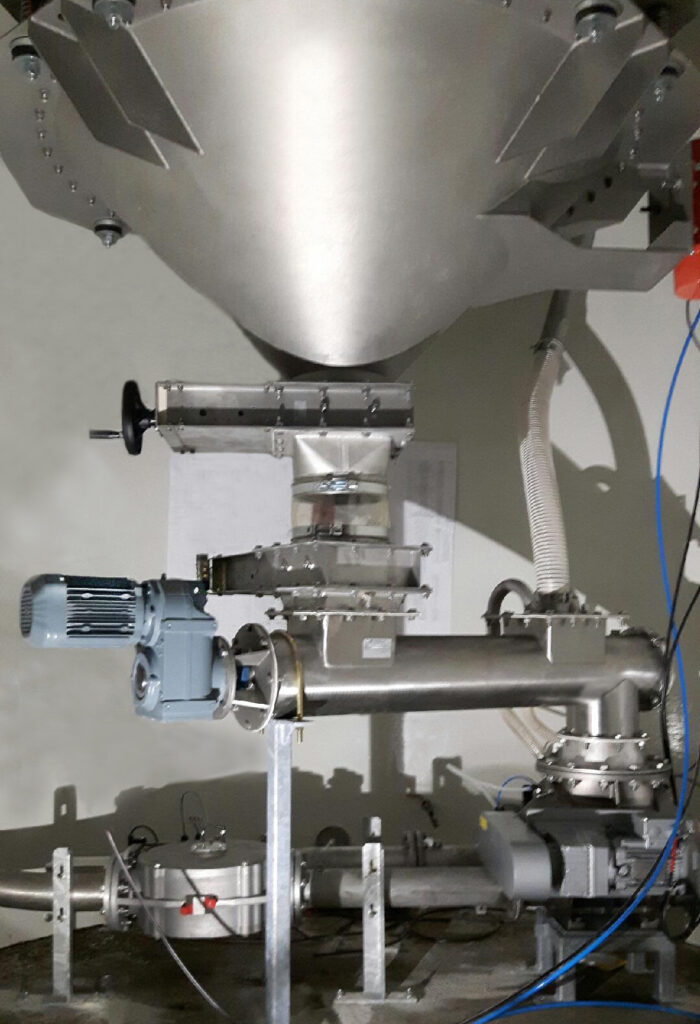

At the heart of WAMGROUP’s feeding solutions is a design philosophy focused on accuracy, modularity, and integration. The feeders use calibrated screws or conveyor systems to deliver exact volumes of granular or powdered materials. This precision ensures minimum material waste and avoids process fluctuations that could affect product uniformity.

Key features of WAMGROUP feeders include modular components that facilitate easy customisation, maintenance, and scalability. The construction employs materials resistant to abrasion and corrosion, enhancing durability in demanding environments. Additionally, these feeders integrate seamlessly with WAMGROUP’s full range of bulk handling equipment, such as mixers, dust collectors, valves and silos, simplifying installation and operational management.

Industries served range widely—from food manufacturers requiring hygienic designs to chemical plants needing explosion-proof variants. In biomass energy, these volumetric feeders play a vital role in feeding fuel at controlled rates, optimising combustion efficiency and emissions control.

Robust Screw Feeder Technologies

Screw feeders are an essential element in controlled bulk material conveyance, with WAMGROUP recognised for its superior design and manufacturing quality. These feeders feature a helicoid flight enclosed in a tube or trough to transport bulk solids from one process stage to another with consistent flow control.

WAMGROUP designs and manufacture industrial screw feeders to handle various materials, including powders, pellets, granules, flakes and more challenging bulk solids like biomass or plastics granules. The screw feeder geometry—such as diameter, pitch, and rotation speed—is optimised and specialised for each application to maximise throughput and minimise degradation or bridging of materials.

Durability is a standout attribute of WAMGROUP screw feeders. Components are built from high-resistance mild or stainless steels and equipped with wear-resistant coatings or liners, extending service life even in abrasive or corrosive conditions. This ensures lower maintenance costs and reduced downtime.

Energy efficiency and operational reliability are enhanced through innovations such as variable speed drives and intelligent drive units, enabling fine adjustments to the feeding rate and reducing power consumption. Control systems can synchronise feeder operation with upstream and downstream equipment, ensuring smooth process flow.

WAMGROUP screw feeders have proven their value in industries such as plastics manufacturing, where precise dosing of additives and raw materials is critical, as well as in agriculture and wastewater treatment for consistent delivery of biomass or sludge.

Recent Innovations Elevating Feeding Technologies

WAMGROUP continually invests in research and development, advancing volumetric feeding and screw feeder designs in response to evolving industry requirements. Recent innovations demonstrate a strong focus on automation, environmental sustainability, and user-centric engineering.

Dust control is another priority, with WAMGROUP’s development of integrated dust filtration technologies aligned with stricter environmental regulations. Their solutions capture fine particles at the source, improving workplace safety and reducing emissions.

Modularity has been enhanced further, with new designs enabling users to combine different components quickly for tailored solutions—for instance, coupling volumetric feeders with mixing or feeding units without requiring complex modifications.

Material technologies have also seen improvements, with innovative coatings and surface treatments that reduce friction and wear, extending component lifespans and ensuring uninterrupted performance.

These innovations empower industries to meet challenges like digital transformation, higher production efficiency demands, and sustainability goals, positioning WAMGROUP as a key partner in future-ready bulk handling technology.

WAMGROUP exemplifies excellence in feeding technology, combining decades of engineering experience with cutting-edge innovation. Its equipment delivers exceptional precision, reliability, and adaptability across demanding industrial sectors. Through continuous development of smart controls, environmental safeguards, and modular design, WAMGROUP ensures that its feeding equipment solutions will remain pivotal in optimising bulk material processing worldwide.

For sectors striving to enhance process accuracy and efficiency, WAMGROUP offers not just products but complete solutions backed by a global network presence and deep industry knowledge.