Why ILT Food Makes the Difference

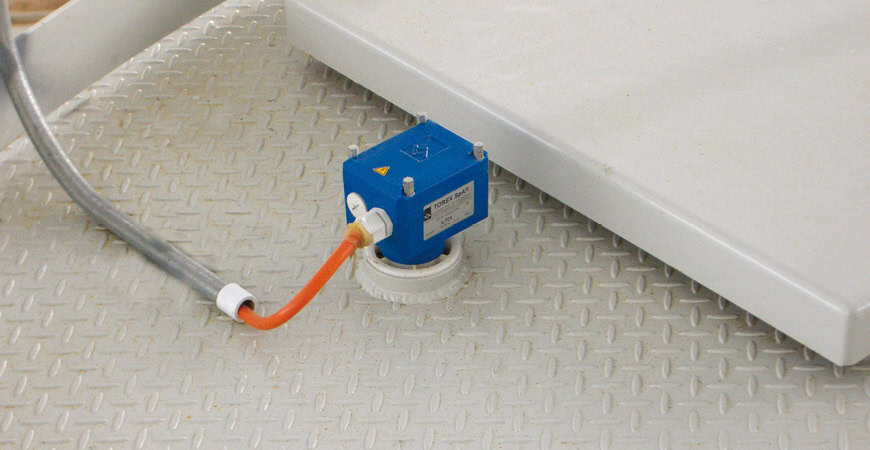

- Food-Certified: The EC 1935/2004 version with IP65 protection is engineered to eliminate product build-up zones. Threaded connections comply with food-contact requirements.

- Dust-Safe Operation: EX II 1/2D (ta/tb IIIC T100 °C) version available on request.

- Easy Integration: Relay interface for PLCs or alarms, with robust and reliable ON/OFF logic.

How It Works in Practice

The rotating paddle detects product presence; torque reaction stops the motor and triggers the relay. When the level drops, the system automatically restarts. The operation is binary, stable, and easily diagnosable — ensuring dependable level control over time.

Versions and Compliance

- ILT Food: EC 1935/2004, IP65, EX II 1/2D; current release without shaft extensions.

- ILT Standard / ATEX: Same working principle, compatible paddle and shaft accessories, dedicated ATEX configuration available.

Typical Food Industry Applications

Sugar, flour, starch, semolina, powdered or granular ingredients, and additives requiring minimum/maximum level detection under hygienic conditions.

Key Specifications

- Connections: G 1½”, G 2½”, 1¼” NPT (Standard / ATEX)

- Connection Material: Plastic (Standard / ATEX), Aluminium (Food)

- Temperature Range: Ambient –20 ~ +60 °C; Process –20 ~ +80 °C

- Maximum Pressure: 0.8 bar

- ATEX Rating: II 1/2D Ex ta/tb IIIC T100 °C Da/Db (on request)

Options & Accessories

- Threaded bushes (adaptors)

- Double paddle for light materials (Standard / ATEX)

- Shaft extension (Standard / ATEX only – not available for ILT Food)

Documentation and Support

Technical sheets, configuration options and assistance available through the WAMGROUP® network:

www.wamgroup.com → TOREX® / Level Indicators section