Applications include processing rice, wheat, corn and other cereal grains for final product, flour or feed production, and other food production processes, such as chopping and flaking products before further processing.

Benefits of Moisture Control:

- Improved milling quality – Proper moisture softens the grain, reducing breakage and increasing flour yield.

- Consistent product quality – Uniform moisture ensures even processing and better texture in the end products.

- Reduced energy consumption – Optimised moisture levels help avoid over-drying or excess steaming, reducing energy use.

- Minimised spoilage and mould – Controlling moisture prevents conditions that promote fungal growth during storage.

- Better storage stability – Properly conditioned grain is less likely to crack or go rancid over time.

- Increased processing efficiency and reduced process downtime – Machines run more smoothly and with less wear when grain moisture is in the ideal range.

Where to Measure Moisture?

There are two common measurement locations:

- Conditioner input: Measuring the moisture before entering the conditioner allows the control system to calculate the correct water to add in the tempering step.

- Conditioner output: Measuring the moisture leaving the conditioner enables a feedback loop to provide consistent product quality and enables adjustment for variations in the process.

Measuring and controlling the moisture ensures the material is not too wet or dry. This optimises the product for the following process stages.

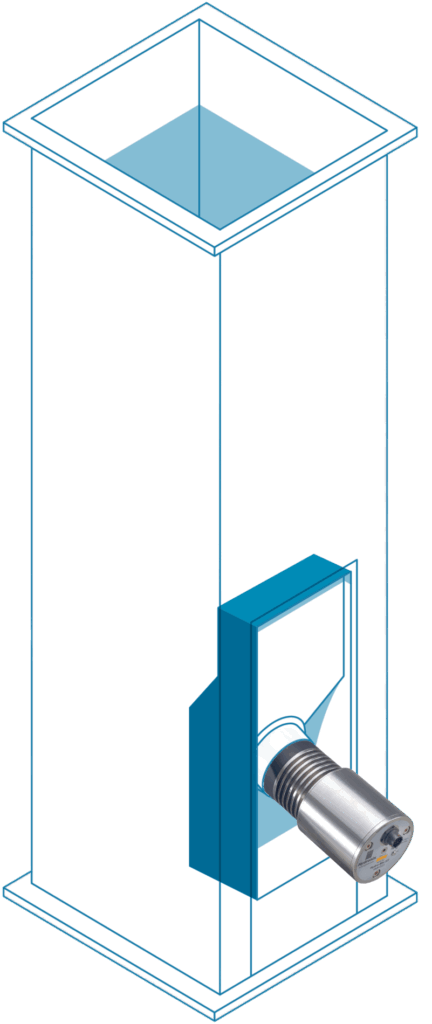

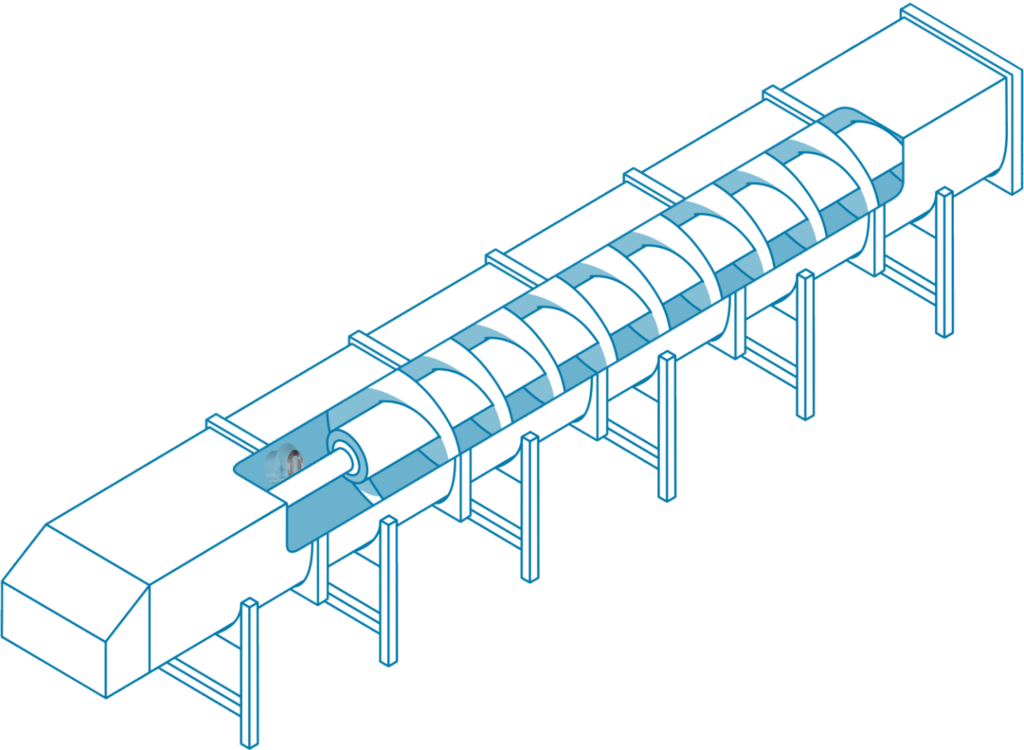

Recommended Installations:

- Ducting system: The sensor is mounted in a ducting system, ensuring consistent flow and speed. The sensor can be mounted vertically or at an angle

- Screw conveyor: The sensor is mounted in the belly of the conveyor, at 30° from the underside and ideally before the sampling point.

Conclusion

Controlling the moisture before and after conditioning grains is vital. It improves their quality by providing a consistent product, reducing spoilage and mould, optimising processing, and increasing shelf life.