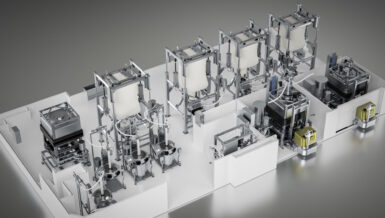

The measurement locations are the dryer exit, the feed-out screw conveyors of the chip silo, and the distribution screw conveyors upstream of the conditioning silos. The measuring devices are installed flush in the outer walls of the screw conveyor or conveying equipment without installed devices or collectors impeding the flow of the product.

The low color fluctuations and the different sizes of the chips do not affect the measurement because the MoistureScan technology is independent of color and size.

This ensures very precise and long-term stable measurement. The measuring devices measure both surface and core moisture of the chips as the microwaves used penetrate the chips completely. The devices are low-maintenance, long-term stable, and do not require constant recalibration.

Precise moisture measurement permits dryer control and consistent chip quality. The work for sampling and reference measurements is reduced, and regular laboratory measurements are no longer necessary. Consistent chip quality results in optimum conditions of the material on the press and minimizes the required electrical power and matrix wear.

AT A GLANCE

Moisture measurement systems

- MoistureScan; MoistureScan XT for temperatures up to 140 C°

- Method based on 2-parameter microwave technology

- Especially suitable for bulk materials (chips, pellets)

- Can be used directly in the product flow, 600 measurements per second

Characteristic

- Independent of density and weight

- Independent of color, structure, and surface

- Measures the core and surface moisture

Advantages

- Low calibration effort

- Very accurate and fast measurement

- Excellent long-term stability

- Fast and timely detection of faults

- Remote servicing/online support possible

Benefits

- Die Production is continuously and quickly informed about the process

- The production costs are minimized

- The proportion of waste is reduced

- The process throughput times are optimized