With these challenges in mind, consistent inventory management becomes more essential than ever. Manufacturers require streamlined, automated systems that provide visibility into ingredient storage vessels, calculate accurate inventory valuation, and enable anticipatory logistics planning.

BinMaster offers a solution with reliable level sensors and inventory programs tailored for the food processing industry. Working in tandem, continuous sensors and remote monitoring software support production, reduce labor, and allow for cost savings that can be strategically applied to appropriately scale existing or new systems.

Sensors for a Smarter Supply Chain

When choosing level sensors, processors must consider the extent of visibility they need into bulk solid and liquid inventory in bins, tanks, silos, hoppers, and mixers.

Real-time inventory levels are ideal for ongoing processes where replenishment, automated pump control, and precise batch levels are a necessity. Point-level alerts provide overfill and dry run protection to ensure operations can continue without interruption. The combination of point and continuous level measurement introduces a comprehensive approach to bulk material management.

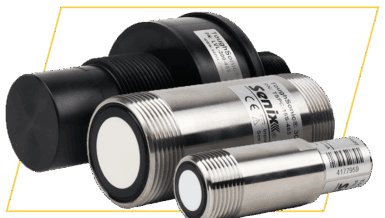

Radar, ultrasonic, and capacitance technologies are commonly found in food and pet food processing plants with sanitary or clean-in-place requirements.

- Non-contact radar sensors measure levels reliably in steam, fluctuating temperatures, turbulence, and buildup or condensation on the sensor face. Compact models like the CNCR-100 and CNCR-200 series are often used in confined spaces—such as mixers, hoppers, or batch tanks—but can also measure full-size containers up to 98 ft. (30 m).

- Ultrasonic transmitters—like the ToughSonic® series with stainless steel or chemical-resistant housings—are known for their durability and versatility, making them an ideal choice for liquid-level measurement in applications ranging from wet ingredients and batched slurry mixtures to water and sanitation chemicals.

- Mini capacitance probes are designed for point-level detection and high- or low-level alerts in pipes, hoppers, or small tanks; MCP-100 liquid detection sensors also offer proactive leak detection in pump rooms.

How Sensors Contribute to Sustainable Operations

Many customers identify sustainability as a priority when shopping for foodstuffs, whether choosing between plastic or biodegradable packaging or identifying products that feature better-for-you or sustainably sourced ingredients.

On the industrial side, sustainability must also be regarded through the lens of labor shortages and supply chain complexities. While some companies turn to AI for predictive modeling, others may not be able to implement the latest technology due to insufficient labor capacities or an inability to upskill employees.

Level sensors help free up workers’ time, allowing labor to be allocated to high-value tasks. When plants introduce machine learning models, BinCloud® software provides both current and historical data to assist in developing eco-friendly choices.

BinMaster’s solutions offer sustainability and transparency via:

- Optimized Water Usage: Meter water use during processing, the cooling of industrial equipment, recycling, and clean-in-place practices. Determining the optimal volume requirement for each process reduces costs and water waste.

- Better Batch Precision: Sensors ensure proper batching ratios with accurate ingredient measurements. This reduces the risk of rejected or out-of-spec product due to improper dosing, leading to less material waste.

- Simplifying Digitization: Remote monitoring and continuous measurement data offer operators automated control over inventory with a shorter learning curve than artificial intelligence models often involve.

- Labor Savings: Workers no longer need to climb storage bins, tanks, or outdoor silos to measure inventory manually. Levels can be displayed on local consoles near storage vessels, integrated into house controls, or viewed remotely on BinCloud.

- Low Cost of Ownership: BinMaster sensors are designed to offer users a long, productive service life. Sensors offer simple installation and initial configuration, require little maintenance, and provide a swift return on investment.

Software’s Real-Time Role in Improving Efficiency

BinCloud inventory management software offers a multitude of tools to optimize orders and deliveries, support logistics, and connect multiple departments throughout food processing operations. From finance to purchasing to the plant floor, all teams view the same data in real-time, helping to minimize miscommunication and maximize productivity.

- Automated Text & Email Alerts: When levels in storage or processing vessels reach pre-set high or low levels, the appropriate staff are notified to take immediate action and ensure uninterrupted production.

- Multi-Site Visibility: Supervisors tasked with running several sites can toggle between viewing an individual bin, all containers on one site, or more than one site at once. “QuickViews” display all data on one interface for convenient oversight.

- Ordering Capabilities: Pick-ups and deliveries can be coordinated within the app, including order history for quick and easy re-ordering.

- Compatibility with Vendor Managed Inventory (VMI): Improve communication with suppliers and eliminate costly work stoppages and last-minute deliveries. Vendors can view bulk material levels and know exactly when and how much to replenish.

- Personalized User Roles: Large, multi-site operations require more users to have access. Tailor custom roles, personalize permissions, and configure parent/child site relationships to keep data secure.

Adapting to the Present—and Future—of Food Processing

As compliance requirements shift, prices and supply chains remain volatile, and customers seek healthier and cost-friendly alternatives, processors must respond to operational roadblocks with proactive solutions. Level sensors and remote monitoring software help manufacturers anticipate these obstacles with reliable forecasting and actionable data.

BinMaster’s continuous level sensors and BinCloud software are highly scalable and designed to support food and beverage businesses’ needs as they grow. From small mills to multi-site corporations, simpler collaboration, enhanced safety, consistent quality, and maximized efficiency are just a smart system away.