The FlowSlide Solid Flow Meter from Hense Wägetechnik offers an advanced solution for measuring the mass flow of free-flowing bulk solids with high precision and reliability.

How the FlowSlide Solid Flow Meter Works

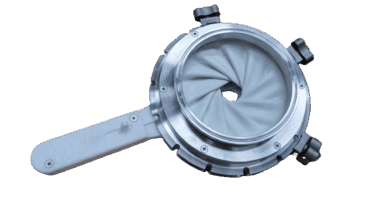

The FlowSlide Solid Flow Meter operates on the centrifugal force principle, where material is directed onto a curved measuring slide. As the bulk material flows over the slide, it generates a force proportional to the mass flow rate. This force is detected by a load cell, which converts it into an electronic signal. The system is designed to deliver continuous, real-time data on material flow rates (kg/h) and total (kg), making it ideal for process optimization in various industries.

Applications in Bulk Processing Industries

The FlowSlide Solid Flow Meter is widely used in industries that handle free-flowing bulk materials, including:

Food and Beverage Industry

In the food industry, accurately measuring powders such as cereals, sugar, cocoa, and starch is critical for maintaining recipe consistency and production efficiency. The FlowSlide ensures precise dosing and blending of ingredients, reducing waste and improving product quality. Parts in contact with the product are made of stainless steel in various grades.

Chemical and Pharmaceutical Sectors

In chemical and pharmaceutical production, precise material flow monitoring is essential to ensure accurate formulation and to meet strict quality control standards. The FlowSlide Solid Flow Meter helps manufacturers maintain consistent batch quality while minimizing raw material losses.

Plastics and Polymer Manufacturing

Raw materials such as plastic granules, flakes, agglomerates, additives, and powders must be accurately dosed to maintain the desired material properties for plastics and polymer production. The FlowSlide provides precise measurement, ensuring the correct composition of polymer blends.

Building Materials and Cement Industry

Precise material flow control is essential for efficient production and cost management in industries handling cement, lime, and other mineral powders. The FlowSlide Solid Flow Meter enables accurate flow monitoring in pneumatic conveying and gravity-fed systems, reducing material waste and optimizing resource utilization.

Key Advantages of the FlowSlide Solid Flow Meter

High Measurement Accuracy

The FlowSlide provides exceptional accuracy, ensuring that even slight variations in material flow are detected. This precision enhances process stability and product quality across various applications.

Maintenance-free

No moving parts are built in the FlowSlide scale, and it is practically maintenance-free. This results in a longer service life and no operational costs. For highly abrasive products measured with the scale, the parts in contact with the product can be made of different wear-resistant materials.

Compatible with Various Bulk Solids

The FlowSlide is designed to handle a wide range of bulk materials, from fine powders to coarse granules, making it a versatile solution for different industrial needs. For proper operation, the products measured must be free-flowing and not sticky.

Real-Time Data for Process Optimization

As inline measurement with continuous data output, the FlowSlide enables real-time monitoring and process adjustments, helping manufacturers optimize their production lines for maximum efficiency.

Integration with Existing Systems

The FlowSlide Solid Flow Meter can easily be integrated into bulk conveying systems, providing real-time flow measurement without disrupting operations. It supports various industrial communication protocols, allowing seamless connectivity with process control systems.

Choosing the Right Flow Meter for Your Application

Selecting the ideal flow meter depends on material properties, flow rate, and system configuration. Hense Wägetechnik offers expert consultation to help businesses choose the best solution, whether a standard flow measurement system or an individual solution.