Process reliability with varying bulk materials – no need for recalibration

The Challenge

The product range included various materials such as roasted coffee beans, ground coffee, instant coffee, chicory, and cocoa. Instant coffee, in particular, may contain sugar and milk powder, depending on the variety, which creates a particularly sticky substance during mixing – a real challenge for level measurement technology.

In the packaging line, a solution was needed that ensured reliable point level detection even with frequently changing bulk materials while also meeting strict hygiene requirements.

Key Challenges at-a-glance:

- Varying material properties during alternating operation

- Strong buildup of fine and sticky powders

- Abrasive stress caused by continuous material flow

- Wide temperature fluctuations: -40 °C to +100 °C (-40 °F to +212 °F)

- High switching frequency during ongoing operation

- Compliance with strict hygiene regulations

Another important aspect: the sensor technology had to operate with minimal maintenance and be hermetically sealed from the process in order to ensure product purity and system safety.

Our Solution: Vibrating Fork Vibranivo® VN 4020

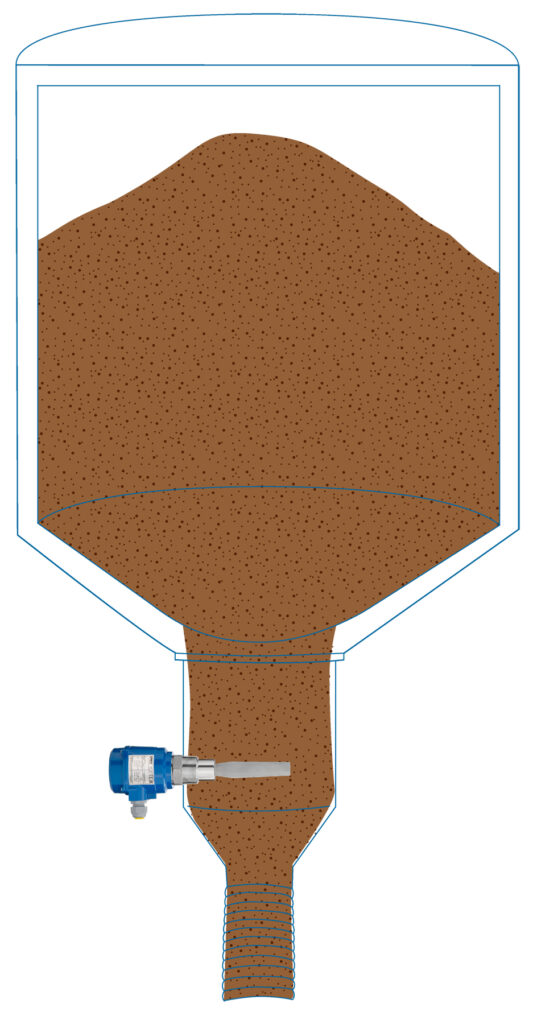

For this application, the Vibranivo® VN 4020 vibrating level switch proved to be the ideal solution thanks to its high flexibility and reliable performance during frequent product changes. Its intelligent sensor technology detects different bulk materials – without the need for calibration or adjustment.

Installed laterally in a 50–90 cm high stainless steel container, the vibrating fork reliably prevents empty runs and ensures a smooth packaging process – even under demanding conditions.

Key Advantages at-a-glance:

- Material-independent: detects instant coffee, milk powder, sugar, and chicory without the need for adjustments

- Hermetically sealed: reliably protects the process area from dust ingress

- Maintenance-free in continuous operation: ideal for frequent switching under demanding conditions

- Hygienic & robust: smooth stainless steel surfaces (1.4404 / 316L), temperature-resistant from -40 °C to +150 °C (-40 °F to +302 °F)

- Compact design: easy side-mount installation, even in confined spaces

Vibranivo® – Reliable Performance in Demanding Applications

The Vibranivo® VN 4020 demonstrates its strengths wherever changing bulk materials, high switching frequencies, and challenging process conditions – such as heavy buildup or temperature fluctuations – come together.

Its short extension ensures maximum robustness, making it ideal for mechanical stress in continuous operation. Thanks to its fully stainless steel construction, the vibrating fork is also perfectly suited for use in hygiene-sensitive environments.

Your benefit: a maintenance-free, cost-efficient point level switch for a wide range of bulk solids – made entirely of stainless steel, process-safe, calibration-free, and ready for immediate use: Plug & Play with maximum reliability.

Key Features of the VN 4020 at-a-glance:

- Calibration-free plug & play operation

- Adjustable sensitivity for different bulk materials

- Switchable logic (Fail Safe High / Low)

- When using universal electronics (DPDT), the NivoLED® signal lamp can be mounted directly onto the sensor to provide a visual indication of the switching status for quick status monitoring

The VN 4020 combines reliable point level detection with maximum ease of use and process visibility – ideal for today’s production environments.