It is therefore essential to rely on explosion-proof sensor solutions with recognized certifications such as ATEX, IECEx or other international approvals when planning and operating silo systems. In such applications, level measurement systems must not only ensure maximum safety but also operate reliably under dusty conditions, temperature fluctuations, and mechanical stress – while allowing for easy integration into existing processes.

A Practical Solution from the Mill: Reliable Level Measurement in Hazardous (Ex) Areas

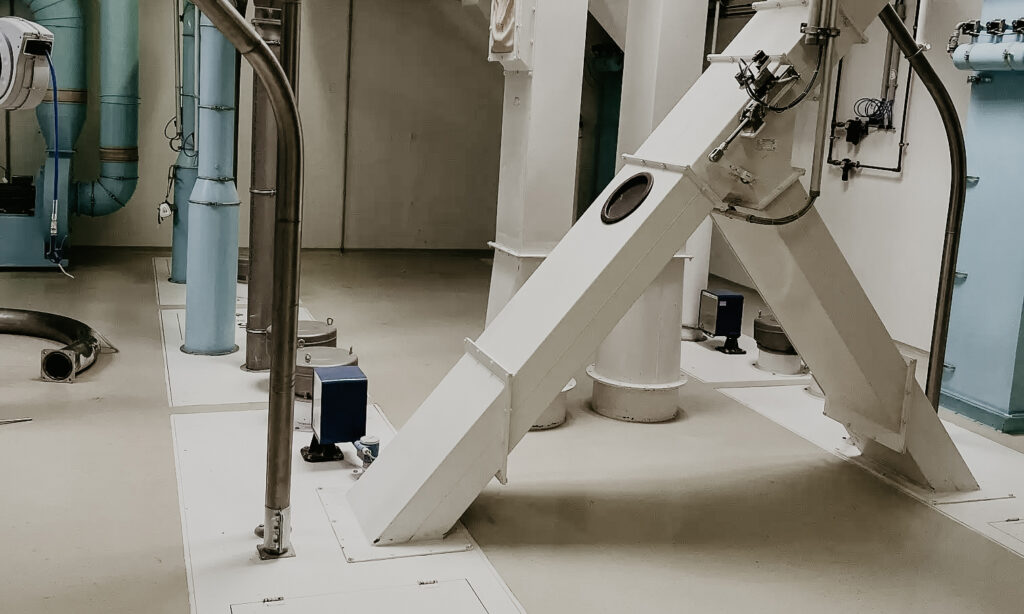

At a mill in Austria, the intermediate storage of grain in a 12-meterhigh silo (approximately 39 feet) needed to be reliably monitored. The requirements included continuous level measurement, complemented by precise point level detection to prevent overfilling and empty run conditions. The sensors had to be easy to integrate into the existing control system, operate with minimal maintenance – and all of this within a hazardous area classified as Zone 20/21. Additional challenges included heavy dust generation and pressure surges during filling.