Kinder Australia have the innovative solution – unmatched and industry-first.

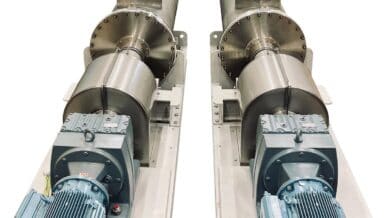

K-Glideclean® is Kinder’s cutting-edge conveyor belt cleaner engineered to excel in high-temperature environments of up to 250°C continuous operation.

Building on the success of Kinder’s K-Glideshield® proprietary high-speed / high-capacity impact bars, K-Glideclean® belt cleaner innovation offers temperature resistance and seamless installation on belts with mechanical fasteners or connections. It cleans effectively without harming the belt.

K-Glideclean® utilises the same K-Glideshield® proven composite material with a low coefficient of friction, with a remarkable 40% reduction compared to UHMWPE and other materials. Additionally, it features good thermal conductivity to efficiently dissipate surface heat, certified fire resistance, and high chemical resistance for superior performance in challenging industrial environments.

When it comes to alternative belt cleaner blade materials, K-Glideclean® is the superior choice.

Tungsten: While Tungsten offers longevity and high-temperature resistance, its aggressive nature makes it unsuitable for belts with clips, mechanical fasteners, or worn surfaces. K-Glideclean® combines temperature resistance with belt-friendly performance, ensuring effective cleaning without risking damage to the belt.

Polyurethane: Preferred for its forgiving nature, Polyurethane is ideal for belts with mechanical fasteners or worn surfaces. However, its temperature resistance is limited compared to K-Glideclean®. With a maximum temperature resistance of 125°C, Polyurethane falls short in high-temperature applications where K-Glideclean® excels.

The K-Glideclean® Innovation Story

K-Glideclean® was designed by Kinder’s engineering team in response to a mining/metallurgy client’s difficult situation handling the extraction, processing, and smelting of copper ore. Due to the high temperature environment, the existing Tungsten H-Type belt cleaners conducted the ambient heat from the furnace and subsequently damaged the conveyor belt. These blades consistently melted within 1 day of installation, requiring the conveyor to be shut down and a full set of blades changed.

Since the development and installation of K-Glideclean® the Maintenance Teams couldn’t be happier with the result.

K-Glideclean® installation delivered a remarkable 804% increase in scraper life – from 177 hours to approximately 1600 hours.

If high temperature material is melting your conveyor cleaning blades away, look to Kinder Australia’s engineered solution that will survive the high temperature and work effectively with your existing clips and mechanical fasteners. K-Glideclean® offers exceptional durability and heat resistance, ensuring reliable performance even in the most demanding environments.