The team at Kinder Australia have developed an innovative system that has been designed to do just that – Keep the belt aligned, level and true. It’s called the K-Commander® Conical Tracker.

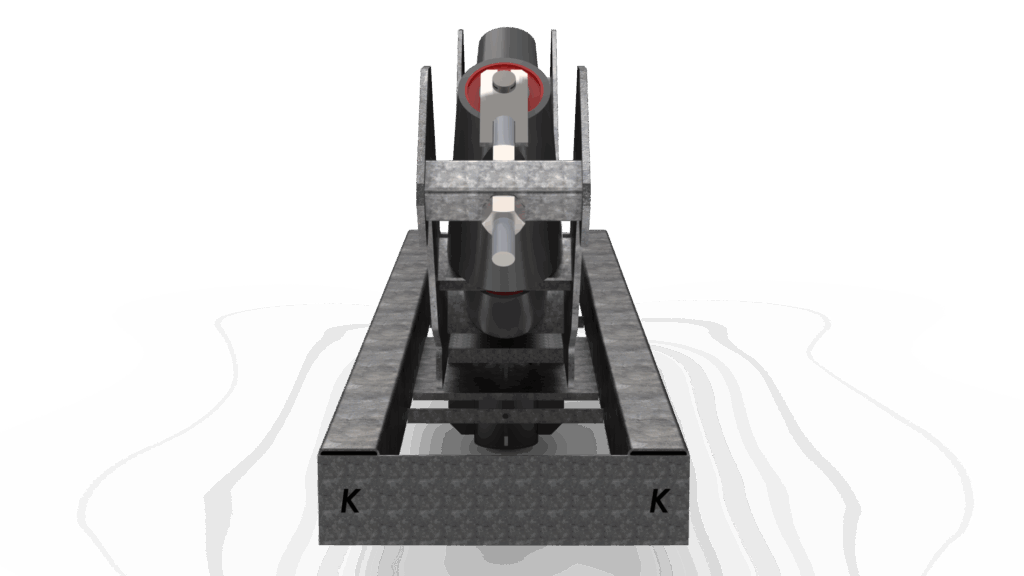

Featuring a unique conical shape, the engineering ingenuity behind K-Commander® Conical Tracker’s braking design is derived from understanding and utilising variations in tangential speed across the roller face to incite this braking action. This action drags the tracker forward on the side that the belt is mistracking towards.

The K-Commander® Conical Tracker operates without the need for the belt edge to make contact, which is conventionally needed to engage tracking motion. To add to this, unlike other tracking systems that rely on contact with a side guide roller to activate tracking, the K-Commander® Conical Tracker is an active belt tracking system that continuously tracks the belt.

The symmetrical design of the K-Commander® Conical Tracker provides a significant advantage, as it allows for use on reversible belts without requiring belt edge contact.

Height adjustable brackets and cantilever roller adjustment mean the standard item suits both inline and offset profiles in all trough angles.

Overall, the K-Commander® Conical Tracker represents a significant advancement in conveyor belt tracking technology. By combining advanced tracking features with a durable design, this innovative system is poised to help sites improve productivity, whilst reducing maintenance downtime as a result of damaged conveyors.