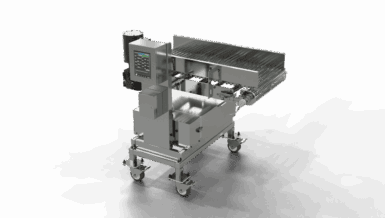

The K-Shield Impact Belt Support System is engineered to improve material containment at high-impact conveyor transfer points, a critical area where material spillage and belt damage often occur. Traditional conveyor systems can struggle to manage the heavy loads, and dynamic forces present at these transfer points, leading to costly maintenance, downtime, and environmental challenges such as dust and material loss.

Recognising these industry challenges, Kinder has developed the K-Shield Impact Belt Support System as a robust, long-lasting solution. Every cradle is custom engineered to suit a wide range of heavy material applications, offering the rigidity needed to stabilise the belt and load at the point of transfer. Unlike traditional idler rollers that can lead to uneven load distribution, the K-Shield supports the belt continuously across the entire surface area.

A standout feature of the system is its 12mm thick UHMW polyethylene wear surface, allowing the conveyor belt to slide freely over the cradle. The smooth, curved trough design helps support the belt uniformly, resulting in more effective sealing by the skirting and less chance of material escape. In turn, this not only protects the conveyor belt from edge damage but also reduces spillage – an important environmental consideration.

The environmental advantages of effective material containment are significant. Preventing spillage means less dust generation, fewer clean-up requirements, and lower risk of materials contaminating surrounding land and waterways. For industries conscious of their environmental impact, investing in systems like the K-Shield Impact Belt Support System is a practical step towards achieving more sustainable operations.

Durability and simplicity are at the heart of the K-Shield’s design. With no moving parts, there’s a reduced risk of mechanical failure, leading to longer service life and lower maintenance demands. This modular system can be tailored to suit virtually any conveyor build and is designed to be easily interchangeable with existing idlers, helping to maintain consistent belt height without costly reconfiguration.

If extra stability is required for demanding mining and high-speed applications, K-Shield can also be manufactured with proprietary K-Glideshield® high speed impact bars. These proprietary composite bars enhance the system’s performance with features like a very low coefficient of friction (less than 0.1), and excellent compressive strength. The K-Glideshield® bars also boast anti-static properties to prevent spark generation – a crucial safety consideration in explosive or flammable environments – and are fire resistant and anti-static (FRAS) certified.

Service temperature is another area where K-Glideshield® excels, capable of handling continuous temperatures up to 250°C and short-term peaks of 300°C, making it suitable for the most extreme operational conditions. This added resilience ensures conveyor systems can maintain peak performance even under tough conditions, ultimately extending the lifespan of equipment and reducing the need for frequent replacements.

The benefits of installing the K-Shield Impact Belt Support System extend well beyond equipment protection. By stabilising the load and reducing material spillage, operations can achieve a more consistent throughput, less downtime for clean-up, and better working conditions for onsite personnel. Less dust and spillage also contribute to a safer, cleaner workplace, aligning with modern expectations for occupational health and safety.

In an era where operational excellence must go hand-in-hand with environmental stewardship, Kinder’s K-Shield solution offers a compelling answer. It not only improves the efficiency and reliability of conveyor systems but also helps organisations reduce their environmental impact through better material containment and reduced waste.

Kinder’s 40 years of experience in designing bulk materials handling solutions are evident in every detail of the K-Shield Impact Belt Support System. It’s a smart investment for companies looking to optimise their operations while contributing to a more sustainable future for the bulk handling industry.

If your business is seeking a proven, engineered solution to contain material more effectively and protect your conveyor systems for the long term, Kinder’s K-Shield Impact Belt Support System is ready to deliver.