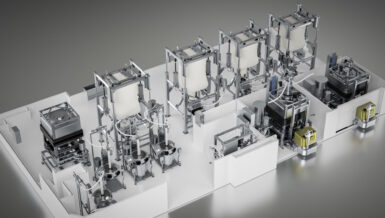

Tamtron’s solutions are well-suited for producing battery metal precursors and cathode active materials (CAM). The process typically involves multiple powder components that must be accurately dosed and mixed to ensure high-quality end products. Tamtron’s systems are designed to support reliable, traceable, and consistent production results.

Modular and scalable technology

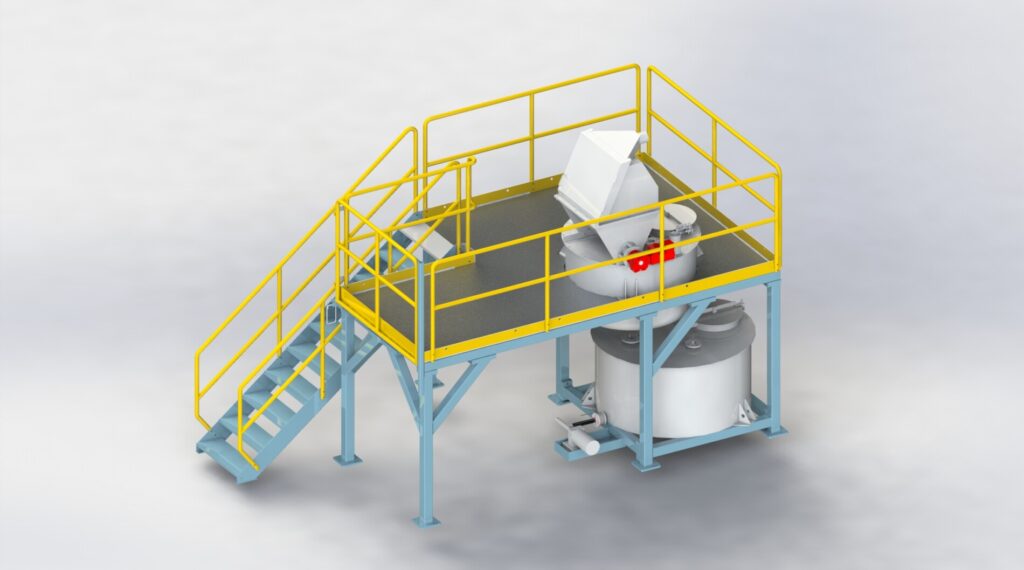

One of Tamtron’s strengths is the modularity and scalability of its systems. These solutions can be easily adapted to the customer’s needs and expanded as production grows. The systems are suitable for new production facilities and the modernization of existing plants.

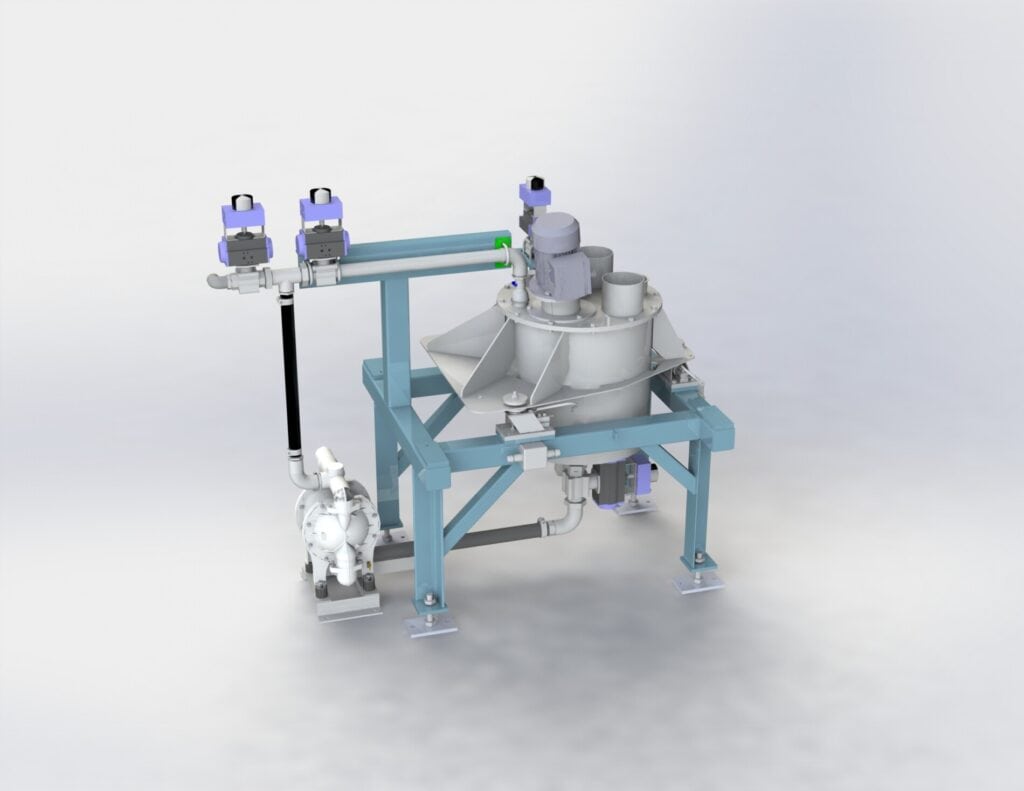

Tamtron’s mixing solutions provide:

- Accurate and repeatable dosing of powdered materials

- Controlled material flow and dust-free operation

- Reliable mixing results for consistent product quality

- Smooth integration into various production environments

- A high level of automation to improve efficiency

All equipment is designed for demanding industrial use and meets the high safety and quality standards required in the production of battery materials.

Contributing to the green transition

Battery materials are key in supporting the global shift toward more sustainable energy. With Tamtron’s solutions, customers in the battery industry can achieve better competitiveness and improved sustainability through efficient and precise production processes.

By focusing on dosing accuracy, process reliability, and scalable solutions, Tamtron enables battery metal producers to meet the demands of a fast-developing industry today and into the future.