The mixer is equipped with heat exchange surfaces both on the cylindrical body and the two flat end plates, ensuring even thermal distribution throughout the mixing chamber. The heating fluid is diathermic oil, up to 150 °C, allowing for a stable and controlled energy transfer.

Designed to operate under full vacuum conditions (<5 mbar abs), the system reduces the boiling point of residual moisture, enabling low-temperature evaporation while preserving the chemical and sensory properties of the product.

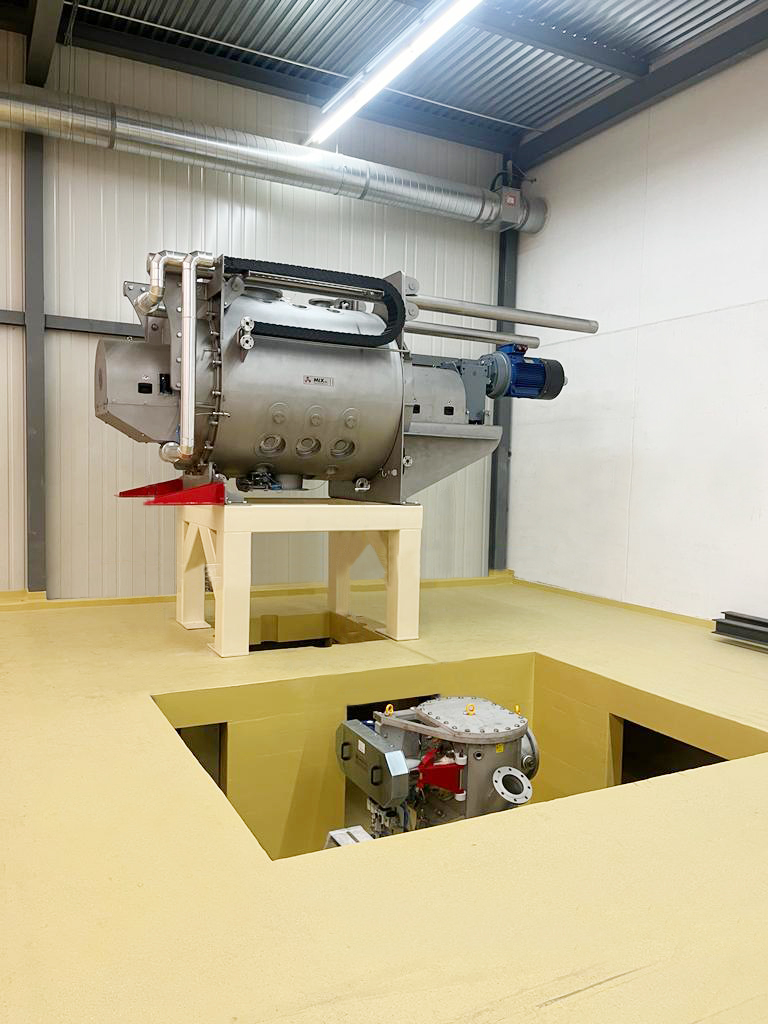

At the heart of the machine is a paddle rotor shaft, which ensures optimal mixing even during the injection of liquids with varying viscosities. A key feature is the Extractashaft design, allowing for the full extraction of the rotor, significantly reducing cleaning time and enhancing sanitisation procedures in line with cosmetic industry standards.

A static filter completes the setup, efficiently managing vapor extraction during the initial drying phase and retaining fine dust particles once the product’s residual moisture falls below 1%.

The system is certified as follows:

- ATEX Ex II 1/3D Ex h IIIB T200°C Da/Dc

- Regulation (EC) No. 1935/2004 compliance, built according to EC Regulation 2023/2006

This project showcases MIX’s ability to combine thermal engineering, vacuum technology, and advanced mixing solutions, delivering tailored equipment for demanding, high-specification processes.