IBC tumble blending flips that playbook on its head. By turning the containment bin itself into the mixing vessel, the blender never touches product, changeovers shrink to minutes, and containment becomes the rule rather than the exception. Below is a deep dive into why this technology has become the “smart money” choice for manufacturers and how Custom Powder Systems (CPS) has refined the concept for 2025.

1 | What Makes an IBC Tumbler Different?

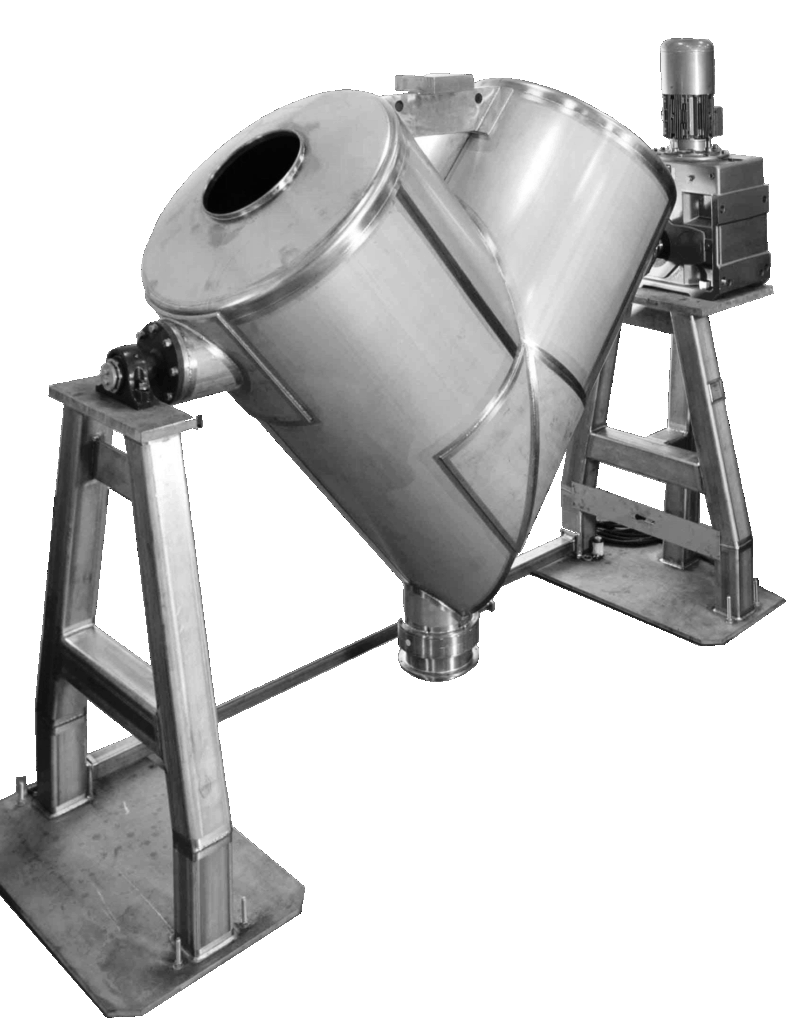

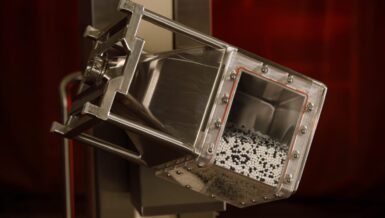

An intermediate bulk container (IBC) tumbler clamps a sealed bin into a rotating frame—often offset 20–30 degrees so powder folds back on itself six times every revolution, creating intense yet gentle mixing action. Because the bin remains closed, the blender frame stays spotless; the only thing you clean is the IBC itself, and that can happen offline while the next recipe is queued. CPS’ standard offset geometry shortens blend times and boosts uniformity without adding shear that can fracture fragile granules.

2 | Five Design Features That Set Custom Powder Systems Apart

| Feature | Why It Matters |

|---|---|

| Total product containment | Product never contacts the blender—just the bin—eliminating airborne dust, cross-batch contamination, and validation headaches. |

| No between-batch clean-ups | Operators wheel the used bin to a wash station while a fresh, pre-batched IBC locks into place. Uptime soars, and cleaning chemicals and water usage plummet. |

| Process-intensifying offset | The 20–30° tilt forces continual direction changes, cutting blend time and homogenizing tricky multi-density formulas. |

| Scalable frames (pedestal & column) | From 50 L pilot bins to 1,800 L production totes, the same motion profile scales linearly. Column blenders even lift and invert IBCs for enclosed charging or drum transfers. |

| Industry 4.0-ready controls | Load-cell mounts, encoder feedback, and Ethernet-IP PLCs feed into MES or digital-twin platforms, unlocking real-time OEE and predictive-maintenance data. |

3 | Solving the Classic Mixing Pain Points

- Changeover bottlenecks: A contract nutraceutical plant running 12 SKUs daily used to lose nearly four hours per shift to CIP and allergen swabs on a traditional ribbon mixer. Switching to IBC blenders trimmed sanitation time to 20 minutes—performed offline—freeing an extra batch window every day.

- Containment & operator safety: Potent compounds once demanded expensive isolators around open mixers. With the bin sealed, operators need only routine PPE, and the facility avoids the six-figure cost of retrofitting a high-potency suite.

- Segregation & product loss: Because powders are pre-weighed into the IBC and remain enclosed throughout the process, there is no product entrainment into air-handling systems—reducing yield loss and simplifying dust-collector disposal.

4 | Application Snapshots Sector

| Sector | IBC Tumbling Wins |

|---|---|

| Pharma & Weight-loss Drugs | Closed bins maintain GMP containment while short blend times protect heat-sensitive APIs. |

| Battery-material Lines | Eliminates metal dust exposure and allows quick recipe pivots from NMC to LFP chemistries. |

| Food & Nutrition Powders | Allergen segregation—soy today, dairy tomorrow—without separate rooms. |

| Specialty Chemicals | Frames with explosion-proof drives and nitrogen-purged bins tackle reactive blends safely. |

5 | Sustainability and Compliance in One Stroke

Cleaning a 2 000-liter ribbon mixer can consume hundreds of gallons of water and caustic solution per cycle. When the blender itself never sees product, those utilities vanish from the equation. Multiply that by dozens of daily changeovers and the Scope 3 footprint savings quickly dwarf the capex. Meanwhile, auditors appreciate a process flow where each batch remains sealed from weigh-up through discharge—closing many of the contamination loopholes cited in FDA 483 observations.

6 | Integrating with the Wider Mixing Ecosystem

IBC blending doesn’t replace every agitator on the floor—it complements them. High-shear inline mixers can wet out gums or carbomers before the slurry returns to the tumble blender for final homogenization; column frames can even dock the same IBC under a lift-and-invert station to gravity-feed filling machines. Because CPS designs containers, lifts, and isolators in-house, plants can build a closed-loop material-handling system without juggling multiple OEMs.

7 | Is an IBC Blender Right for You?

Ask three quick questions:

1. Do I lose more than 30 minutes per changeover to cleaning?

2. Is cross-contamination or dust exposure a top-five risk on my hazard analysis?

3. Do I run multiple SKUs of similar batch size?

If you answered “yes” even once, an IBC tumble blender could reclaim both uptime and peace of mind.

Why It Matters

In an era of labor shortages, tighter GMP scrutiny, and razor-thin production margins, container-centric blending offers a rare triple win: higher throughput, cleaner operations, and future-proof digital connectivity. Custom Powder Systems didn’t invent the IBC tumbler—but after 2 decades of niche powder-handling projects, they’ve polished it into a scalable, sensor-rich workhorse built and supported in the USA. Ready to see the numbers for your line? Explore the IBC Blender lineup or connect with CPS’ engineering team for a personalized ROI model. Contact us at https://custom-powder.com