With over six decades of experience, the company combines German engineering, advanced technology, and innovative spirit, establishing itself as one of the world’s leading manufacturers of industrial and solid mixers.

From pioneer to global brand

MIXACO’s success story began in 1965 with the goal of rethinking industrial mixing technology. As early as 1968, the company presented the first combined heating/cooling mixer, followed in 1975 by the revolutionary container mixer. This internationally patented invention set new standards and radically changed everyday production in many industries. Building on these early successes, MIXACO has established itself as a global brand recognized for quality, precision, and technological leadership.

Innovation as a driving force

Innovation has always been and remains the driving force behind MIXACO. In 2004, the company introduced the Multitool™ container mixer, a further step forward in the mixing of solid materials. In the same year, the owner family repurchased all the company shares, reaffirming its commitment to independence, quality, and sustainable development. With the establishment of MIXACO USA LLC in 2009, international expansion began, while in 2014 the largest industrial mixer ever built was completed, with a capacity of 10,000 liters, a symbol of extraordinary engineering and performance.

Progress through technology

MIXACO has continued to innovate in recent years. In 2021 and 2022, the heating/cooling mixer series was completely redesigned and the CM i4 fleX was launched with a new patent, confirming the company’s commitment to shaping the future of mixing technology. At the same time, MIXACO has strengthened its logistics with a new external warehouse to respond even more efficiently to customer needs. In 2024, the Bonding series was mechanically redesigned and the software further developed, combining efficiency and precision. With the founding of MIXACO Machinery Technology (Changzhou) Co., Ltd in China in 2025 and the introduction of the Infinity Mixer™, the company expanded its global presence and set new standards for flexibility, precision, and performance in industrial mixing.

Infinity Mixer™ – New standards in industrial mixing

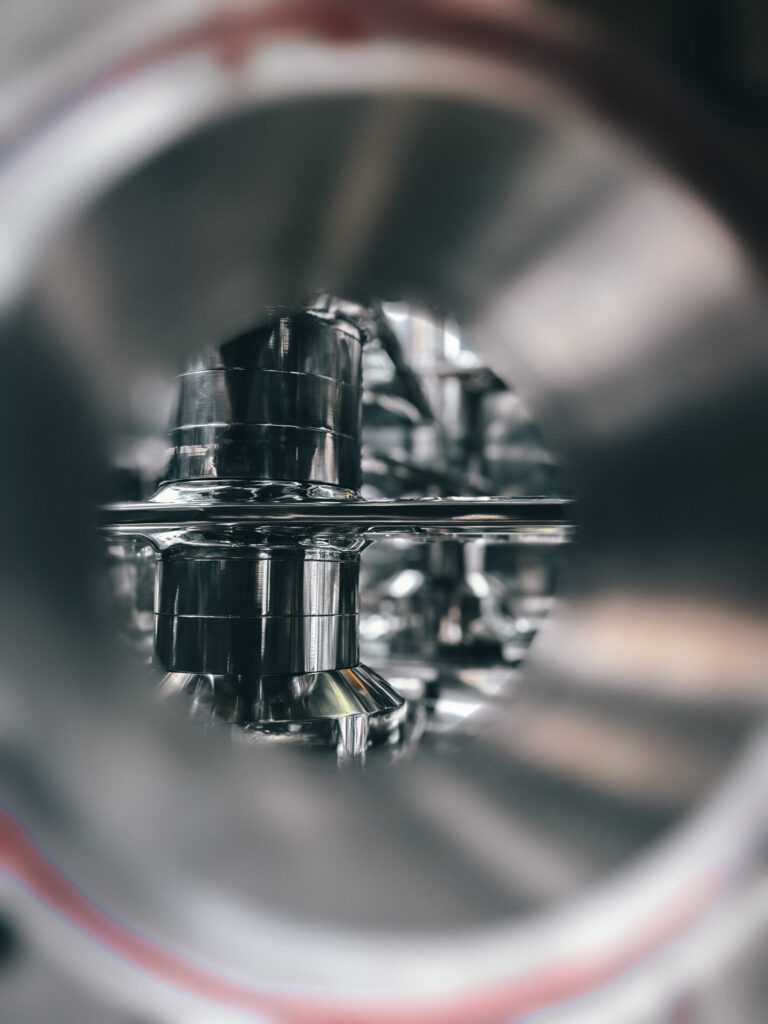

The Infinity Mixer™ represents MIXACO’s ultimate innovation. The combination of two mixing containers, each with its own set of tools, allows for extremely high-intensity mixing, reduced mixing times, and maximum energy efficiency. The distortion and circulation patterns generated in a controlled environment ensure consistent, uniform quality, while the optimized geometry of the blades allows even difficult powders to be processed. The modular structure of the tools facilitates cleaning and quick material changes. With mixing speeds of up to 80 m/s and overlapping tools that eliminate dead zones, the Infinity Mixer™ ensures uniform and reliable results even with complex mixtures of powders and granules.

This mixer is suitable for numerous industrial sectors: in the plastics industry for masterbatches, compounds, and PVC; in the battery industry for dry and semi-dry electrode processing; in the food industry for hygienic homogenization of materials; and in the pharmaceutical industry to ensure consistent quality of tablets and powders. The Infinity Mixer™ combines high performance, energy efficiency, and flexibility, setting a new standard in industrial mixing. MIXACO also offers the possibility to test it with customers’ materials to experience its practical advantages firsthand.

The MIXACO mixer range

The differences between the various MIXACO mixers concern the mixing principles, production capacities, and intended applications.

- The CM i4 enables fully automated mixing with digital integration for Industry 4.0 environments, while the CM i4 fleX is designed for quick batch changes and ensures contamination-free mixing. The Vortex model, with its innovative tool geometry, optimizes material flow and ensures precise mixing of masterbatches, chemical compounds, and specialty powders.

- High-speed mixers enable fast, homogeneous mixing in short cycle times while maintaining high energy efficiency. Intensity mixers are ideal for heavy materials or complex processes such as PVC and masterbatch.

- Heating/cooling mixers combine precise temperature control with high mixing speed to best treat heat-sensitive materials.

- Universal mixers suitable for powder, granules, fibers and pastes. These single shaft horizontal mixers combine performance and flexibility to homogenize dry ingredients in a short time or to evenly incorporate liquid additives without lumps. Working with temperature and pressure or in Atex classified zones makes these mixers suitable for food applications, nutraceuticals, chemicals.

- Laboratory mixers are designed for research and development, offering the same quality as industrial systems: Laboratory container mixers are ideal for small batch testing and easy to handle, while laboratory heating mixers allow precise temperature control for sensitive formulations.

A look to the future

MIXACO continues to represent innovation, precision, and quality in industrial mixing. The company supports customers worldwide in achieving more efficient, reliable, and cutting-edge processes. For further information or personalized advice, visit the MIXACO website or contact the team directly, who are ready to guide every customer to the next level of mixing technology.