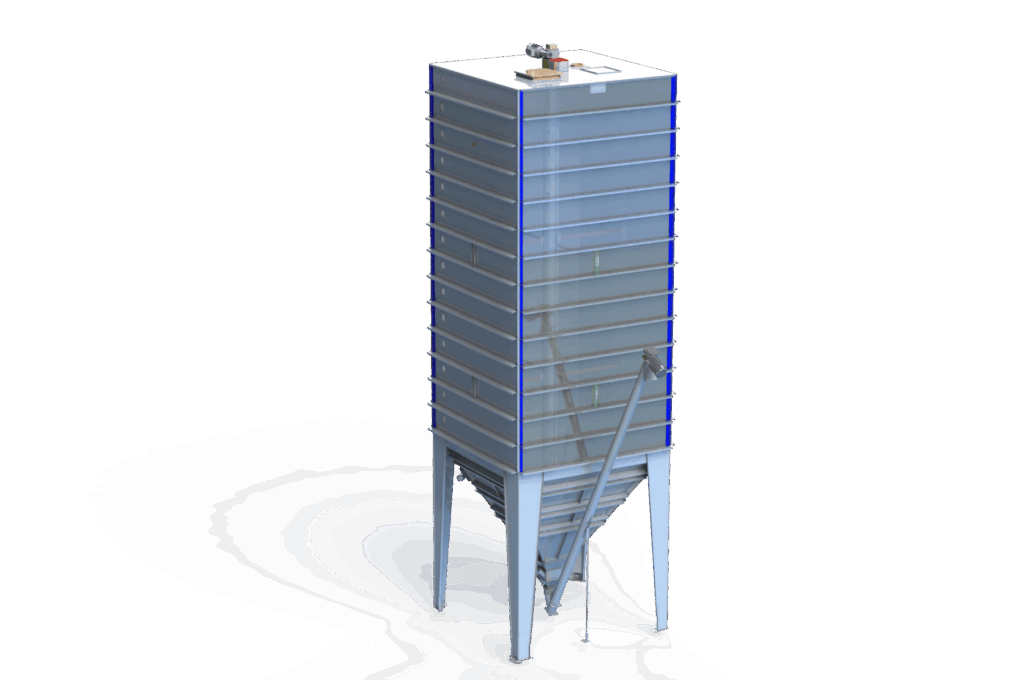

BM Silo’s Auger Mixing Silo offers a robust, modular solution to this challenge—engineered to mix during filling and eliminate batch-to-batch inconsistency.

Core technical features:

- Vertical Ø230 mm auger with continuous pitch – up to 3,200 kg/h at 50 rpm

- Low-shear mixing for temperature-sensitive materials

- Compact footprint (from 1.5×1.5 m to 3×3 m) and capacities up to 66 m³

- Galvanized panels, CE marking, and Eurocode compliance

- Flat-pack delivery for easy indoor installation without disrupting production

Case: Quantafuel, Norway

Norwegian plastic recycling innovator Quantafuel now operates four BM Auger Mixing Silos, processing over 50 tons of plastic granulate daily. The result:

- Homogeneous product with consistent melt properties

- Improved color stability and reduced rework

- No need for recalibration between batches

- Efficient freight and installation – delivered flat-packed for indoor setup

This mixer silo is not just a silo—it’s a blending system integrated into your storage process. With a modular, service-friendly design and proven long-term performance (15,000-hour motor/bearing lifecycle), it’s built for industrial uptime.

From plastics to powder processing, BM Silo delivers blending where it matters most: at the heart of your operation.

Want to know more? Contact us at sales@bmsilo.com