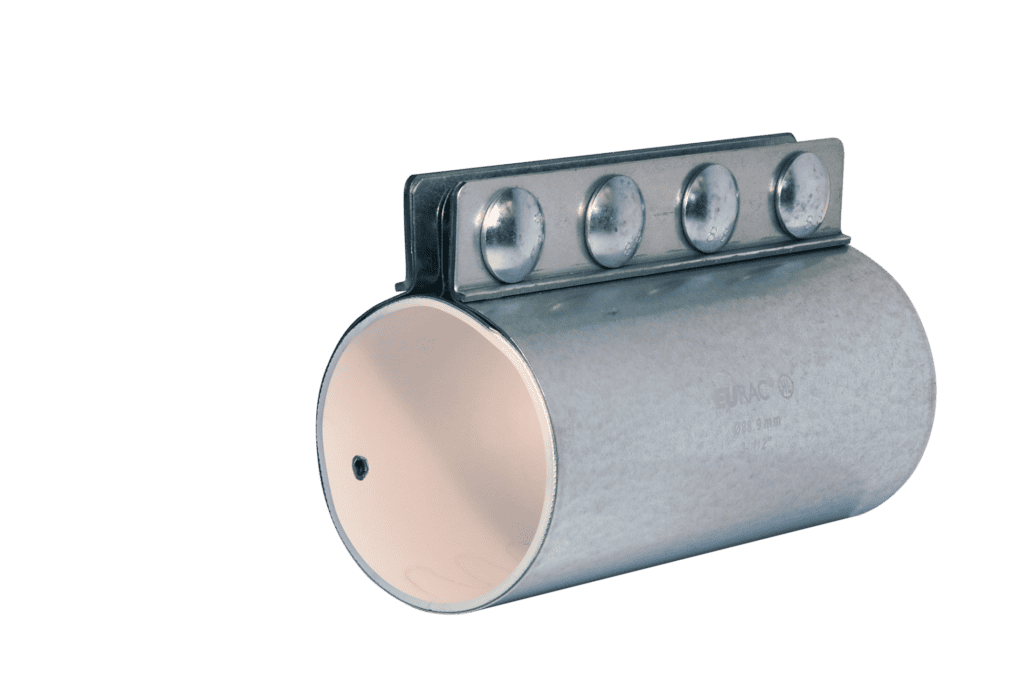

In pneumatic conveying and industrial dust collection systems, the reliability of pipe connections plays a decisive role in overall process performance. For more than three decades, the EURAC® compression coupling range developed by STIF has established itself as a proven technical solution for assembling conveying pipelines, both in dilute and dense phase applications.

A technical alternative to flanged connections

Originally developed at the end of the 1980s, EURAC® compression couplings were designed to address a clear industrial requirement: simplifying pipeline assembly while ensuring mechanical strength and reliable sealing. As an alternative to traditional flanged systems, compression couplings significantly reduce installation time, limit downtime during maintenance, and offer greater flexibility when modifying existing pipework.

Depending on the configuration, the couplings are designed to withstand working pressures of up to 24 bar. EURAC® couplings can be used in vacuum or pressure conveying systems, handling light as well as more abrasive materials. Their design makes them suitable for a wide range of industrial sectors, from chemicals and cement to food processing.

A range structured around process constraints

The EURAC® range is available in several product families to suit different configurations of pneumatic conveying:

- EURAC® L and M couplings, dedicated to dilute phase conveying of light products

- EURAC® HL and H couplings, designed for more demanding dense phase applications

- EURAC® HX couplings, intended for large diameters and high mechanical loads

The range covers pipe diameters from 38.1 mm to 355.6 mm, with standard coupling lengths between 100 and 300 mm, offering considerable design flexibility for industrial conveying networks.

Material selection and regulatory compliance

Depending on the operating environment and process requirements, couplings are available with galvanised steel or stainless steel 430 or 304L outer shell, ensuring resistance to corrosion (304L) and mechanical stress.

A wide selection of gasket materials is available, including SBR, FDA-compliant white NBR, VMQ silicone, blue detectable silicone and Viton FKM, covering temperature ranges from –65°C up to +250°C. Several configurations comply with European regulations 1935/2004 CE and REACH 1907/2006 CE, making them suitable for food and sensitive applications.

To mitigate electrostatic risks, conductivity is ensured through dedicated solutions such as eyelets, conductive strips or stainless-steel protective rings, a critical consideration in powder handling systems.

Pressure performance and operational safety

The mechanical performance of EURAC® couplings is documented through detailed pressure rating curves, allowing operators and designers to determine the maximum allowable working pressure according to pipe diameter, coupling length and installation conditions (free-hanging or clamped pipes).

The entire range complies with the European Pressure Equipment Directive 97/23/CE, with clear product marking to ensure traceability and on-site identification. This contributes to safe operation and long-term reliability of pneumatic conveying installations.

Pipe bends and connectors for controlled product flow

In addition to compression couplings, the EURAC® range includes large-radius bends and stainless-steel connectors designed to maintain smooth product flow and reduce wear. Manufactured in stainless steel 304, these bends feature an internal surface roughness of Ra ≤ 0.8 μm, limiting friction, pressure drop and material degradation.

Pipe connectors allow engineers to design complex conveying routes while controlling turbulence and accumulation zones. External ultrasonic polishing further enhances surface quality and durability.

Supporting the durability of pneumatic conveying systems

Thanks to their modular design, robustness and broad configuration options, EURAC® compression couplings and bends contribute to the long-term performance and durability of pneumatic conveying systems. By addressing key challenges such as mechanical resistance, sealing integrity, electrostatic safety and ease of maintenance, they support industrial operators in meeting today’s efficiency, safety and sustainability objectives in bulk handling applications.