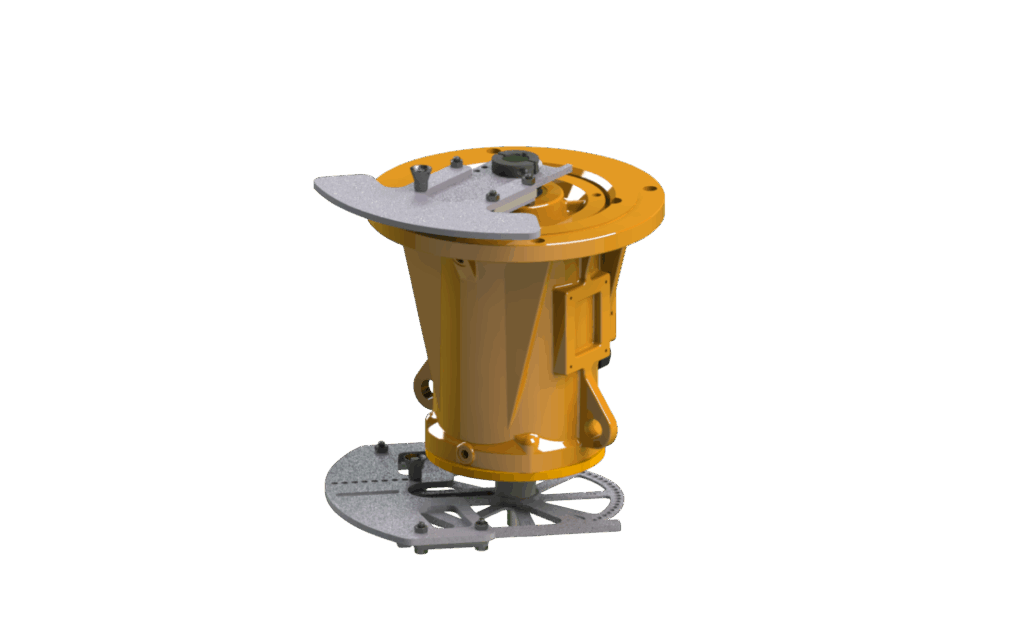

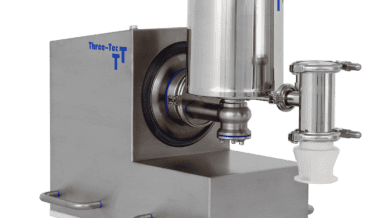

The traditional approach to adjusting eccentric weights in the industry is often slow and complex, typically requiring tools and partial disassembly. In contrast, the new Precision-Flo system effectively eliminates these complications by introducing a tool-free adjustment mechanism that is both quick and efficient. This advancement is particularly advantageous for operators during the initial setup of the screener or for regularly modifying the amplitude settings for various applications.

In operation, the top eccentric weight of a circular screener is essential for controlling the radial movement of material on the screen surface. The heavier this weight, the greater the horizontal amplitude. Conversely, the bottom eccentric weight governs the vertical screen motion, aiding in dislodging particles that clog the screen aperture. The new system is designed for simplicity, eliminating the need for extra weights or intricate adjustments, thereby establishing a new standard in operational convenience and effectiveness.

With Precision-Flo, operators will benefit from:

- Tool-less adjustment: this breakthrough feature allows quick and effortless adjustments. Operators can access all 720 weight combinations by simply pulling a single pin, thereby eliminating the need for disassembly.

- Time efficiency: with Precision-Flo, achieving the ideal lead angle is now a matter of minutes – a stark contrast to the lengthy adjustments required by similar machines on the market.

- No additional weights are required: the system streamlines adjustments without the need for adding or removing weights, making the process much simpler.

- Airlift compatibility: this feature ensures that adjustments and maintenance can be easily managed by a single person, enhancing operational efficiency.

Since February 2024, all new screeners up to and including 72 inches have been installed with the advanced Precision-Flo design. This upgrade is also available for existing VIBROSCREEN screeners of the same size, with a quick, one-hour retrofit process. This ensures that all current and future customers benefit from the latest screening technology.

“Precision-Flo is indicative of Kason’s constant drive to innovate and enhance operational efficiency,” said Dan Chellew, VP Sales & Marketing, Akona Process Solutions. “The design not only saves time but also significantly improves the functionality and user-friendliness of VIBROSCREEN screeners, demonstrating Kason’s ongoing commitment to meeting the evolving needs of its customers.”