Our high-intensity magnetic separators are specifically designed to capture and remove fine metal contaminants that could compromise product safety and quality. This precise contaminant control supports product consistency and builds consumer trust. Magnattack systems meet stringent FDA, USDA and HACCP standards, providing a critical layer of protection that reinforces both regulatory compliance and product integrity.

Constructed from high-grade stainless steel and high-strength magnetic materials, our separators are corrosion-resistant, easy to clean, and built to withstand the demands of pharmaceutical and cosmetic production. Each unit is designed to meet strict hygienic standards, ensuring uncompromised product safety.

Magnattack magnetic separation systems are also optimised for fine powders, granules, and liquid processing – common in pharmaceutical and cosmetic industries. With innovative designs, they efficiently remove contaminants without disrupting product flow, enabling continuous, high-quality production.

Selecting the Right Magnetic Separator for Pharmaceutical Applications

When choosing a magnetic separator for sensitive powder and liquid applications, consider the following:

- Is the magnet of sanitary design and build?

- The separator must be easy to clean, with no cracks or crevices that could harbor residue or bacteria.

- Is it compliant with USDA specifications?

- Magnattack® received USDA Dairy Acceptance Certification for several models, including the Mag-Ram® Self-Cleaning Separator, Rapidclean® Drawer Magnet, Round Pipe Separator, Powder Transfer Magnet, and the Emulsion & Slurry Pipeline Separator.

- Is the cleaning process sanitary and simple to ensure the least possible intrusion to the product zone?

- The cleaning mechanism should minimise intrusion into the product zone and eliminate recontamination risks. Stainless steel sleeves, for example, can harbor bacteria and pose contamination risks during cleaning.

- Can it be easily accessed for cleaning (if a manual-clean design)?

- Manual-clean magnet designs should allow for safe and frequent access for operators.

- In the case of difficult-to-flow products, what means are taken to prevent build-up and binding of cleaning mechanisms? What design criteria is in place to ensure effective magnetic separation is achieved without blockages?

- Features like rotary designs, oscillators, or the Mag-Ram®’s 13-degree rotating rams help prevent build-up and ensure effective separation. Consulting with an expert can be helpful to determine the best solution for the application.

- Is the magnet resistant to abrasion?

- Abrasion can result in magnet strength loss, increased contamination levels, as well as exposure to dangerous rare earth elements. Magnattack magnets with Dura-Slik® technology resist abrasion, preserving magnet strength and safety over time.

- Does the separator assembly consist of high-grade magnetics (such as RE80®) to ensure longevity and maintain magnet strength?

- What means are taken to ensure magnet strength is maintained over time?

- Factors such as impact, vibration, oxygen exposure, heat, and abrasion can degrade magnet strength. Proper handling is essential for longevity and safety.

- Does the magnet comply with current HACCP and best practice standards (e.g. 0909MAGSEP 2-2021)?

- These certifications provide clients with confidence that products are suitable for use in pharmaceutical and food processing, and other critical industries. Ensure compliance with relevant standards to meet industry expectations.

- Is the magnet supplied with proper certification?

- Verify that all necessary certifications are provided to support audits and regulatory requirements.

Magnattack® Magnetic Separators for Pharmaceutical Processing

- Mag-Ram® Automatic Self-Cleaning Magnet

- Designed for dry product lines, this hygienic, self-cleaning separator minimizes contamination and enhances product security while also protecting processing equipment from damage. Its automated cleaning reduces downtime and operator intervention.

- Round Pipe Separator

- Ideal for powder and dry product lines, this separator features a powerful +11,000 gauss rare earth magnet concentrated at the base – where metal contamination typically flows through -providing extra strength at the critical point and preventing magnetic fragments from bypassing the magnet.

- Rapidclean® Drawer & Tubular Magnets

- Revolutionary, easy-to-clean, hygienic drawer magnetic separators with RE80® magnet technology designed to prevent recontamination risks during cleaning. The cleaning process takes place entirely outside of the product stream, allowing operators to access, inspect, and clean the magnet with minimal recontamination risk.

- For low-flow gravity locations where space is limited, the Tubular Rapidclean is an economical and effective solution.

- Rapidclean® Rotary Magnet

- Equipped with RE80® magnetic bar technology, its rotary action prevents process stream bridging and effectively breaks down soft lumps and sticky materials.

- Sanitary Powder Transfer Magnet

- Specifically designed for sensitive powder transfer lines, this USDA Dairy Accepted separator is ideal for pharmaceutical and dairy applications.

- Spherical Pneumatic Transfer Magnet

- Aerodynamically engineered for high-speed pneumatic transfer systems, this separator efficiently removes metal fragments without disrupting flow.

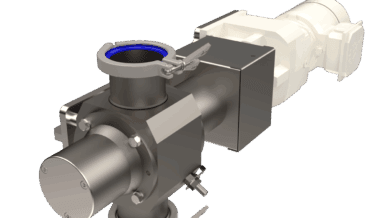

- Pressure Pipeline Separator

- Built for liquid and semi-liquid products in high-pressure pipelines, this separator uses high-strength rare earth magnets to ensure contaminants are securely trapped, even in challenging processing environments, helping to maintain product purity and meet industry standards.

Enhance Your Process With Magnattack

Partner with Magnattack to find the ideal magnetic separation solution for your application. Our advanced, hygienic systems are designed to increase production efficiency, maximise product safety, and protect valuable processing equipment.

Ready to elevate your pharmaceutical safety standards? Contact Magnattack today for a tailored consultation and discover how our magnetic solutions can transform your process.