Jansen&Heuning develops and builds a complete range of size reduction equipment. From fully automated bigbag crushers to compact grain mills, each solution is carefully engineered to match the process layout, the material characteristics and the required throughput.

Bigbag Crushers: The First Line of Defense

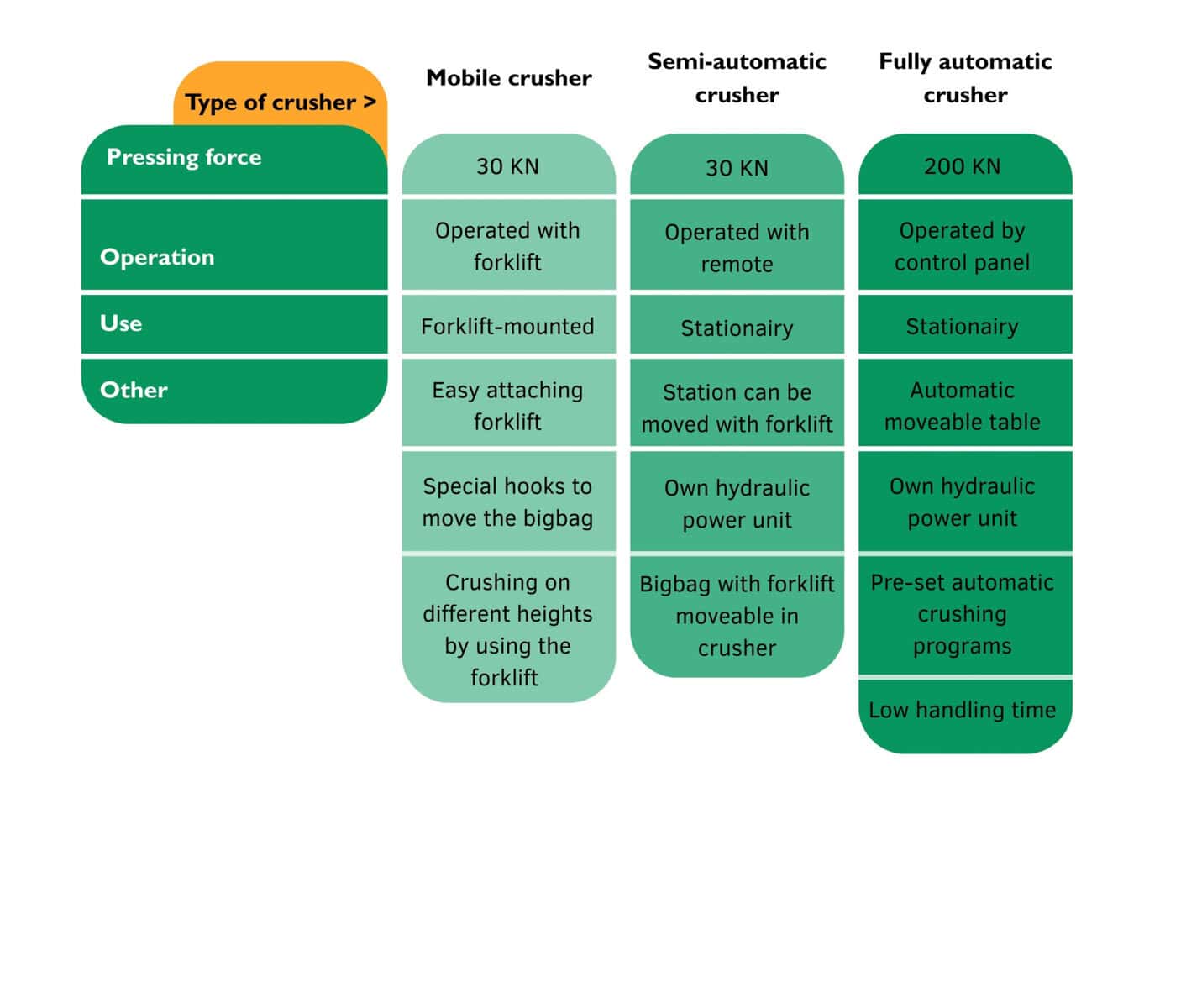

When bulk material arrives on site, it often comes in bigbags. Compaction and agglomeration during transport can make discharge difficult or even impossible. Jansen&Heuning offers three bigbag crusher variants:

- Mobile Crusher – a flexible plug-and-play unit as a tool on the forklift truck that can be moved to different unloading points. Ideal for operations where space or unloading frequency is limited.

- Semi-Automatic Crusher – a fixed installation with loading and and lifting by forklift truck crushing by remote control of the driver. Suited for medium-volume operations.

- Fully Automatic Crusher – an integrated system where bigbags are placed and crushed in a single automated sequence. This solution minimizes operator intervention.

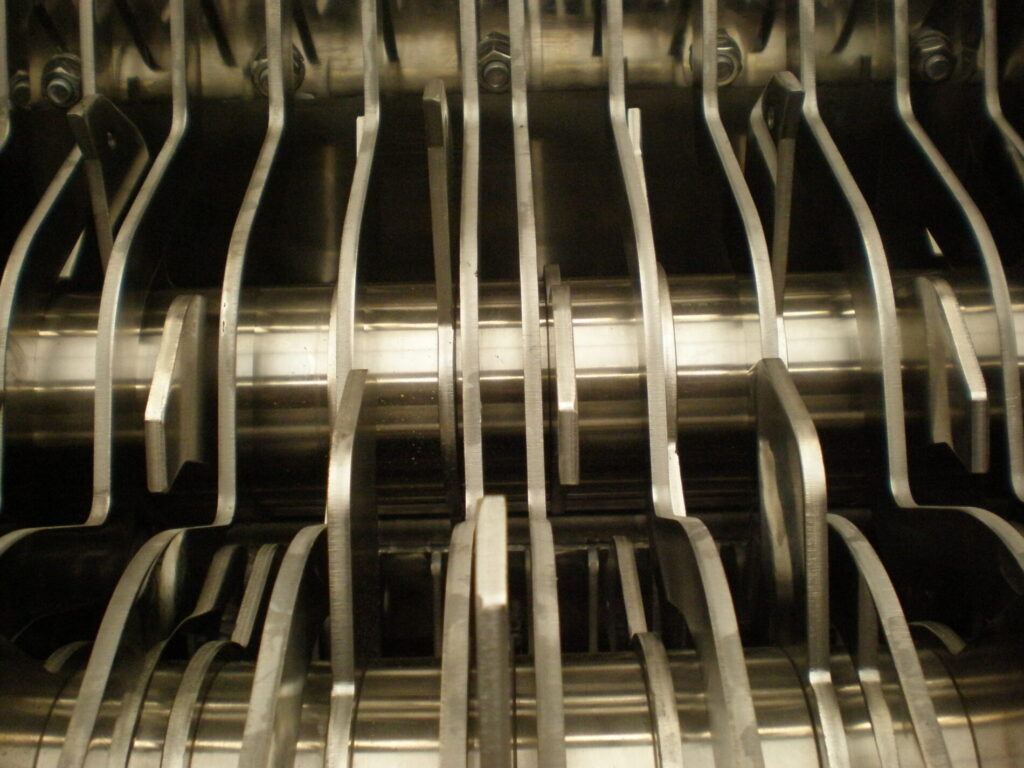

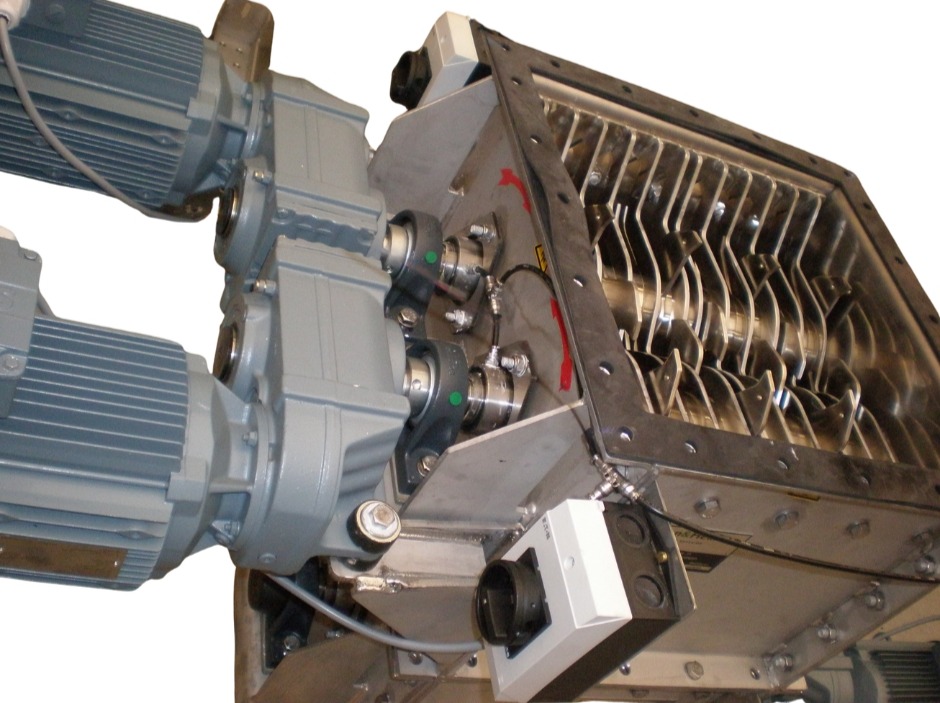

Each crusher uses a robust set of hydraulically driven crushing bars or knives to loosen compacted products and ensure consistent discharge. Safety enclosures, dust extraction, and optional weighing systems can be added to meet site requirements.

Lumpbreaker: Safeguarding Process Flow

Even after initial unloading, compacted lumps can form in silos, hoppers, or during intermediate storage. The Jansen&Heuning lumpbreaker ensures a constant material flow by breaking down hardened lumps just before they enter the next step in the process. The design is compact, low-maintenance, and available with ATEX certification for explosive dust environments.

Grain Crushing: Processing at Particle Level

For agricultural and feed applications, size reduction is more precise: it is about achieving a targeted particle size distribution. Jansen&Heuning offers three solutions:

- Grain Crusher – uses rollers to crack grain kernels while maintaining the husk, resulting in higher feed efficiency for livestock.

- Hammermill – applies high-speed impact to pulverize grain into fine particles, ideal for feed formulations that require homogeneity.

- Discmill – a quiet, energy-efficient solution that produces an adjustable narrow particle size distribution, particularly suited for breweries or specialty milling.

By selecting the right combination of crushers and mills, operators can optimize energy consumption, reduce waste, and improve downstream performance.

Integrating Size Reduction in Modern Bulk Plants

Volume reduction is no longer a stand-alone process step. In modern bulk plants, it is integrated with automation, dust collection, weighing, and quality monitoring. Jansen&Heuning designs its equipment with modularity in mind, so systems can be expanded or reconfigured as operations grow.

Benefits of Controlled Volume Reduction

- Improved Safety – no manual hammering of bigbags or lumps

- Process Stability – constant flow prevents surges and downtime

- Better Product Quality – homogeneous material improves mixing and dosing

- Operational Efficiency – automated systems reduce labor and maintenance

Conclusion

Volume reduction is a critical enabler for reliable bulk handling. Whether it is unloading compacted bigbags, preventing silo blockages, or achieving the right grain particle size, Jansen&Heuning provides a complete portfolio of solutions to keep material flowing. All safely, consistently, and efficiently.