Why Size Reduction Matters

Size reduction is not merely the act of breaking down material—it is a foundational process that enhances uniformity, improves material handling, and prepares substances for downstream processing. When applied strategically, size reduction enables greater efficiency across operations: minimizing waste, reducing energy consumption, and delivering consistent particle sizes tailored to application needs.

While traditional equipment such as hammermills and impactors can achieve these goals, they often do so with trade-offs—particularly in terms of elevated power usage and accelerated wear. Selecting the right reduction technology is therefore not just a matter of functionality, but of long-term operational and energy efficiency.

Roll Crushers: A Time-Tested Solution

Roll crushers have long stood as a reliable and energy-efficient alternative to high-speed impact-based size reduction equipment. Operating on the principle of compressive and shear forces between two rotating rolls, these machines provide consistent, uniform output with minimal fines—offering significant advantages for energy savings and downstream processing.

Controlled Size Reduction Through Shear and Pressure, Not Impact

Unlike hammermills and impactors, which depend on high-velocity collisions to shatter material, roll crushers apply continuous pressure and friction. This approach not only reduces energy consumption per ton but also limits the generation of undesired fines, resulting in a more predictable and process-ready product.

Single-Stage Efficiency

In single-stage applications, roll crushers typically achieve a reduction ratio of up to 4:1 in a single pass—ideal for many industrial applications where uniform sizing is critical. Under optimal conditions—such as with friable materials and larger roll diameters—ratios of 6:1 or even 8:1 are possible, expanding the machine’s utility without additional processing stages.

Double-Stage Power for Tough Materials

When greater reduction is required, a two-stage roll crusher system can deliver ratios of 16:1 or more. With the right material properties and larger roll configurations, this can extend to as much as 36:1—enabling precise handling of even the most challenging feedstocks while maintaining efficiency and product integrity.

A Comparative Perspective

While traditional hammermills and impact crushers often achieve reduction ratios of 10:1 to 12:1 in a single pass, they do so with higher energy demands and often greater wear. Roll crushers, by contrast, offer a more measured and cost-effective solution where material characteristics and operational goals allow.

Energy Efficiency That Delivers Long-Term Value

One of the most significant—yet often overlooked—advantages of roll crushers lie in their superior energy efficiency. Compared to hammermills and impact crushers, which generally consume between 1.5 to 2 horsepower per ton per hour, roll crushers achieve the same material reduction using as little as ¼ to ½ horsepower per ton per hour.

While alternative crushing methods may offer a lower upfront equipment cost, the long-term operating savings of a roll crusher tell a different story. When factoring in energy consumption alone, many operations experience a full return on investment within just 2 to 3 years.

The implications of this energy efficiency extend far beyond utility bills:

- Substantially lower operating costs

- Minimized environmental impact

- Decreased strain on plant infrastructure

- Consistent cost savings across production lines

In industries where margins are tight and sustainability is paramount, roll crushers offer an intelligent, forward-thinking choice that pays dividends year after year.

Applications Across Key Industries

Roll crushers serve a critical role across a broad spectrum of industrial sectors, delivering efficient size reduction for a broad spectrum of materials. Their versatility and reliability make them an indispensable tool in numerous processing applications, including:

- Aggregate and construction material processing

- Cement and limestone production

- Fertilizer and salt handling

- Mineral ore beneficiation

- Recycling and byproduct management

- Coal/Coke preparation

- And numerous other specialized applications…

What distinguishes roll crushers is their ability to produce a highly consistent product size while minimizing the generation of fines. This efficiency is particularly valuable in operations where uniformity, cost control, and energy efficiency are critical priorities. By combining reliability with precision sizing, roll crushers continue to support both traditional industries and emerging applications in sustainable resource use and recycling.

Why Smart Operators Are Choosing Roll Crushers for Today’s Challenges

As industries grapple with rising energy costs and increasingly stringent sustainability mandates, the importance of selecting the right size-reduction equipment has never been greater. Operational efficiency is no longer a luxury—it’s a necessity.

Roll crushers, long recognized for their reliability and cost-efficiency, are experiencing renewed interest as plant managers seek to balance throughput goals with environmental and economic pressures. These machines offer a streamlined, proven solution for precise material reduction—delivering consistent product sizing while minimizing power consumption and maintenance demands.

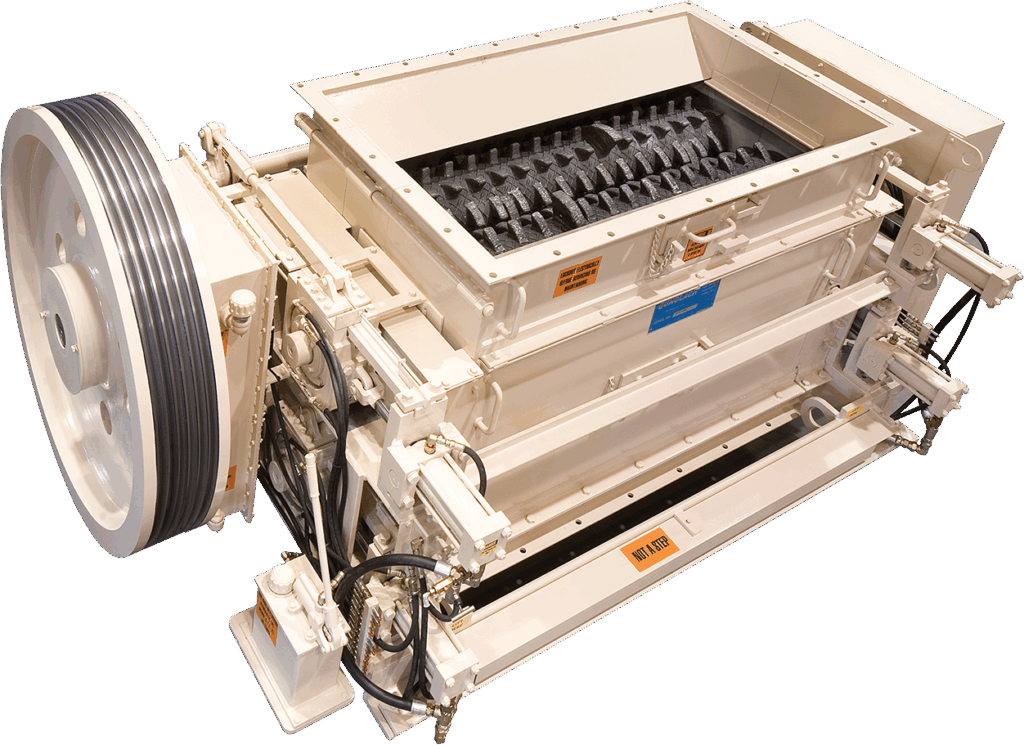

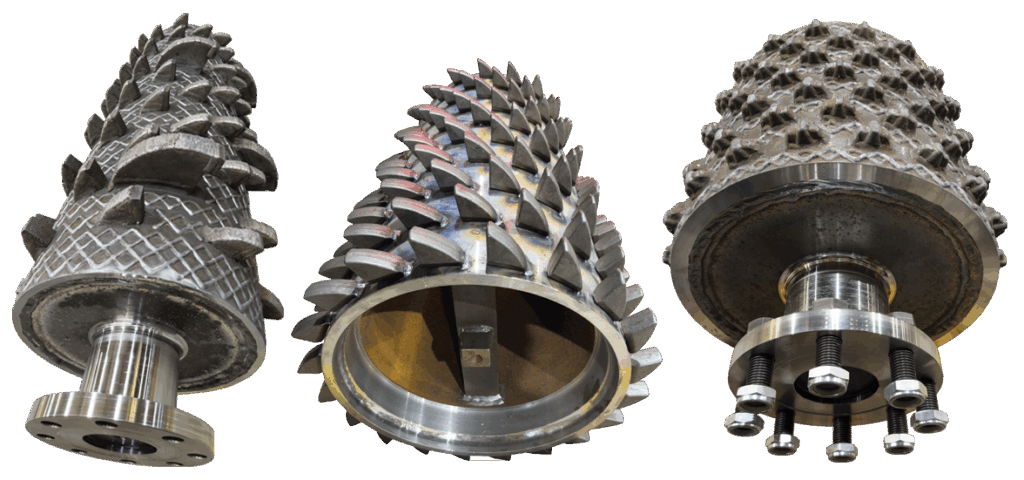

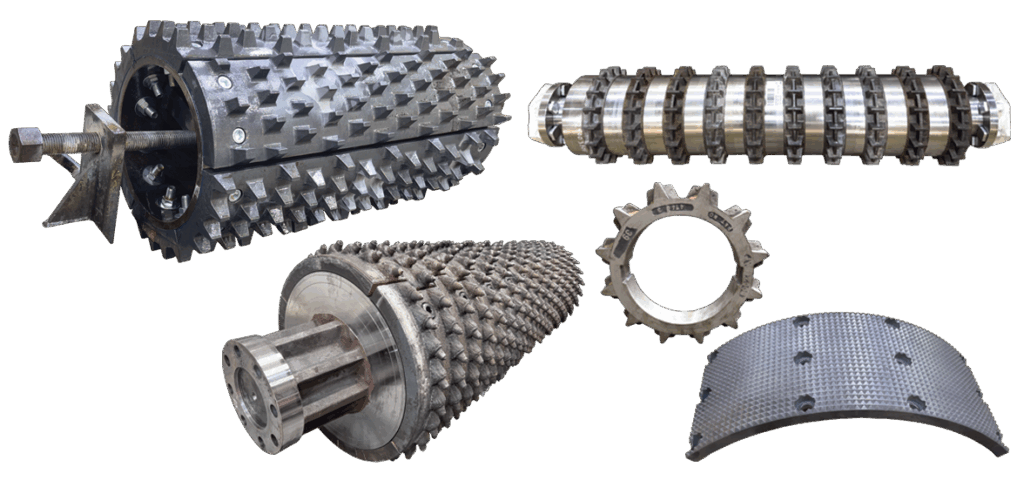

Gundlach’s Double Roll Crusher technologies exemplify this modern approach. Far from being a one-size-fits-all machine, it empowers operators with a high degree of customization and control:

- Tooth size and profile options allow producers to fine-tune the output, achieving highly specific product size distributions.

- Adjustable roll settings enable compensation for wear, ensuring consistent performance over time without costly downtime.

- For even greater resilience, the optional NITROIL® system incorporates hydraulic cylinders paired with a nitrogen-charged accumulator. This patented feature provides automatic tramp relief—allowing uncrushable material to safely pass through the crusher without damaging the rolls.

Whether used in single- or double-stage configurations, roll crushers offer a scalable, operator-friendly solution that aligns with modern production demands. With Gundlach technology, efficiency, precision, and adaptability are built in from the start.