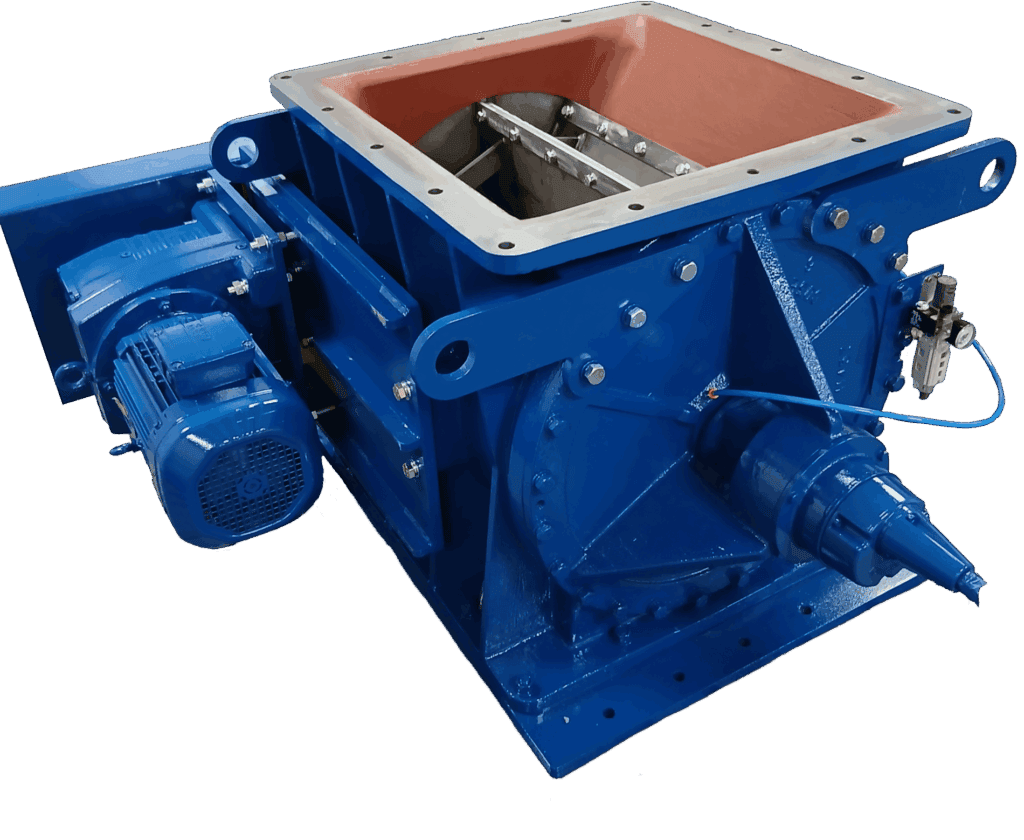

When a long-standing customer came to us asking for unique upgrades to our existing 600mm Rotary Valve we were equal to the task. The customer, a globally recognised biomass energy generator, processes abrasive torrefied wood pellets 24 hours a day 365 days a year.

The torrefaction process, which involves heating biomass in an oxygen deprived environment produces biomass pellets that have a much greater energy density when compared to traditional biomass.

However, the pellets are abrasive and so the valves handling them need to be robust enough to withstand the abrasive nature of the product, the continuous operating hours and maintenance regime at the facility.

In addition to this the valves would need to meet ST2 (10 bar) ATEX explosion barrier certification whilst minimising air loss across the valve to maximise blower efficiency.

Finally, based on our knowledge and experience having worked with the customer we understood the intensive maintenance processes in place which the valve must be able to withstand.

Our solution was in partnership with our customer to design an all-new valve and lay down patterns to cast the main body and end covers. The resulting castings, produced in a high grade of iron are 25% thicker in all key areas. The rotor shaft diameter was increased by 75% and all bearings were uprated to heavy-duty double roller units. Other minor changes to the fixings and fasteners enabled the number of tools required to maintain the valve to be reduced and to ensure they were suited to the intensive maintenance processes.

The result is an extremely robust valve that can handle all that is thrown at it, continuing to operate at maximum efficiency with minimal air loss across the valve resulting in savings through reduced blower requirements.

Kevin Steele, Rotolok Sales Manager stated’ We are extremely pleased with the resulting valve. The process to develop and produce it typifies the unique capabilities we have at Rotolok. Having full control over design, manufacture and build, including casting the bodies and end covers at our own foundry ensures we maintain the high quality our customers have come to expect’.