The customer requires a valve in which they can control the flow of the powders from both dry silos.

The Problem:

Sugar and dried fruit such as raisins and apricots are naturally sticky products which makes it problematic for mechanical parts.

Traditional valves such as Slide valves are no good with handling sugar. When the slide valve closes some sugar is dragged into the valve by the slide plate which crushes the sugar, making the sticky fine powder find its way into the bearing surfaces and seizes it up. This ultimately stops the valve from fully closing which can lead to valves leaking, overfilling the mixer below and food wastage due to spilling. The plant will need to stop for the valve to be cleaned which causes downtime and reduced production. This is a very costly problem for a relatively easy solution.

Ideal Requirement:

The customer requested a valve which allows them to accurately control the flow of the food powder. They need a valve which does not jam. As they are handling food powders they will also need the valve to be manufactured in food approved materials.

Solution:

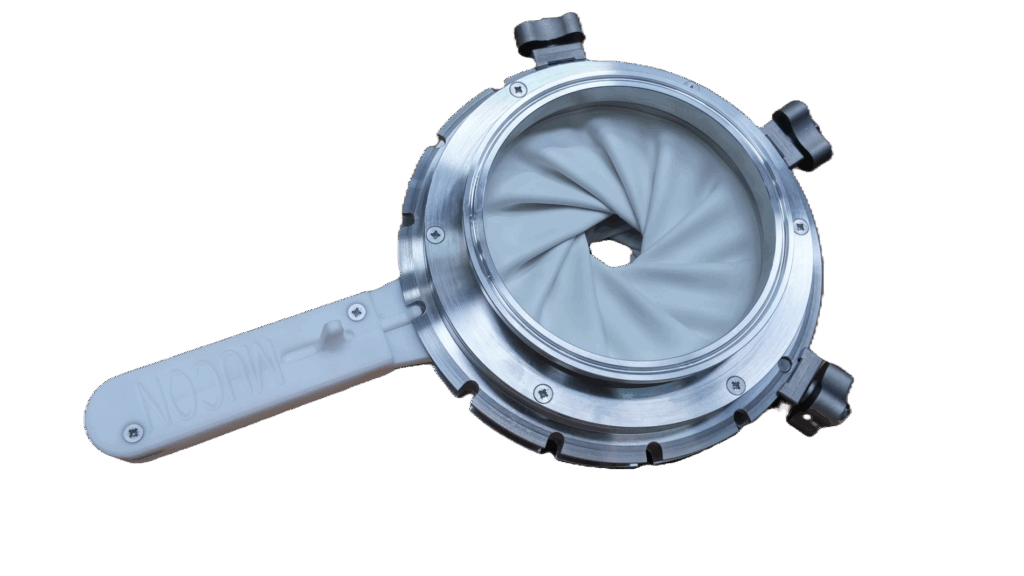

The Mucon Iris Diaphragm Valve is the perfect solution for this application.

Mucon Iris Diaphragm Valve utilises a concentrically closing diaphragm to accurately control the flow of powders and granular material.

In this application we selected the EPDM diaphragm which is FDA approved and a stainless steel body to comply with the strict hygiene requirements in Switzerland.

The bearing surfaces are protected by the diaphragm, which prevents any ingress of material into the workings of the valve, which rules out any risk of the valve jamming.