Whether you’re in food & pet food, plastics & packaging, grain milling, or chemical processing, this gate delivers fast, effective shutoff with minimal system disruption.

Purpose-Built for Simplicity and Control

Push-Pull Slide Gates serve a straightforward but essential purpose:

To manually shut off dry bulk material flow in vacuum or gravity applications—quickly and reliably.

This is especially useful in areas where compressed air or electrical supply isn’t practical or necessary. Operators can manually control product flow with ease, making this gate ideal for maintenance points, emergency shutoffs, or sectioned system isolation.

Key Features That Work Where You Need Them

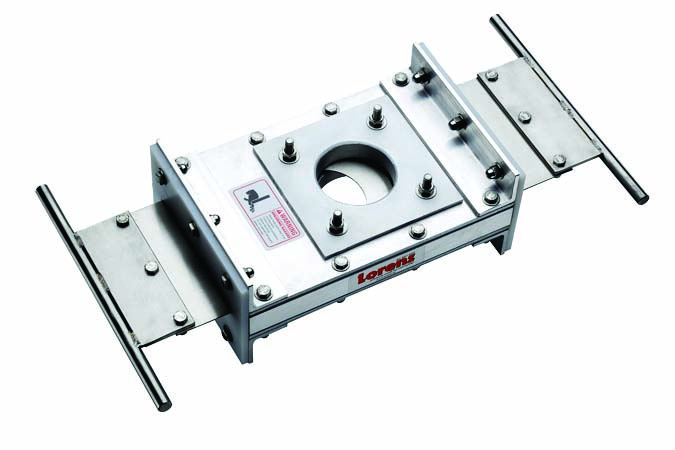

✔️ 304 Stainless Steel Contact Points

For product safety, cleanliness, and resistance to wear, these gates feature 304 stainless steel where it counts—along all product contact surfaces.

✔️ Lightweight Aluminum Frame

Durable and corrosion-resistant, the aluminum frame offers easy installation and reduced system strain, without compromising structural strength.

✔️ Flexible Sizing

Available in sizes ranging from 2” to 12”, Push-Pull Slide Gates are adaptable to a wide range of system configurations.

✔️ Dust-Tight Seals

Maintain clean work environments and prevent product leakage with secure, dust-tight sealing built into every gate.

✔️ Temperature Tolerance

Standard units are rated up to 82°C (180°F), with high-temperature kits available for more demanding applications.

Why Push-Pull?

In facilities where power access is limited or automation isn’t needed, a manual shutoff gate becomes an incredibly valuable tool. Push-Pull Slide Gates offer the same quality construction and material compatibility as Lorenz’s automated solutions—without the complexity or cost of pneumatic or electric actuation.

Benefits at a Glance:

- No power required – Ideal for remote or power-limited areas

- Fast control – Easily isolate or stop product flow when needed

- Low maintenance – Fewer components mean fewer issues

- Hygienic and tough – Built for food, chemical, and industrial-grade performance

Industries Served:

- Food & Pet Food Processing

- Plastics & Packaging

- Grain Milling & Agricultural Products

- Chemical & Industrial Applications

“Push-Pull Slide Gates are a quick solution to shut off your line.”

From maintenance teams to plant operators, these gates provide a simple, hands-on solution for flow control. No downtime for troubleshooting actuators, no delays for power sourcing—just smooth, manual control when you need it most.

At Lorenz Conveying Products, we’re committed to providing fit-for-purpose solutions that work in the real world. Our Push-Pull Slide Gates are just one example of how simplicity, strength, and smart design come together to improve operational flow.

Want to learn more or get help sizing the right gate for your system?

View Catalogue | 905-372-2240 | lorenzproducts.com