In this sense, the gross bagging scale WBE 25 is an interesting alternative that has established itself as a flexible system for the semi-automatic filling of various products into bags.

Highest precision and safety with simple operation

The gross bagging scale WBE 25 is a semi-automatic bagging system that weighs bulk materials directly in the bag. It is designed for a weighing range of 7 kg to 27 kg. Depending on the material, packaging, and operating conditions, the system achieves outputs in the range of around 120 to 160 bags per hour with a bag filling weight of 25 kg.

The bagging scale is available in both stationery and a mobile version. Its compact design facilitates integration into existing production processes without requiring extensive modifications.

At the heart of the system is a precise weighing system that continuously measures and controls the weight during the filling process. It is supplemented by an operating and control unit in which process and dosing parameters can be stored.

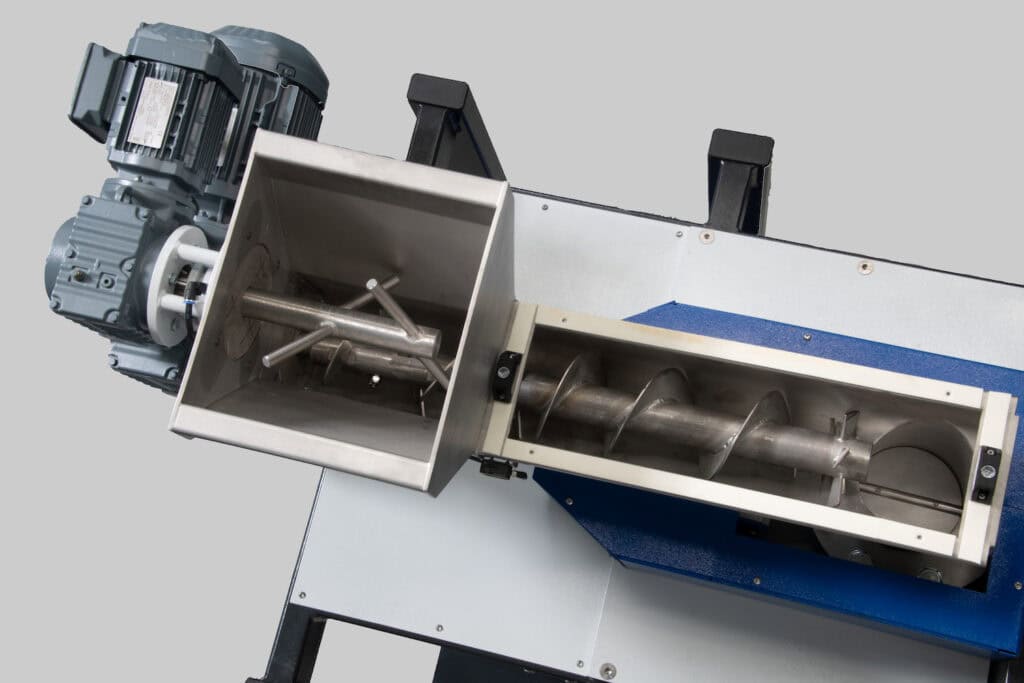

Individual dosing depending on the bulk material

A key feature of the WBE 25 gross bagging scale is the design of the dosing system for the respective bulk material. For free-flowing products, 3-position dosing rotary valves are typically used. For powdery or slow-flowing products, a dosing screw is provided to enable a uniform and controlled material flow.

This modularity is relevant in practice, as many companies process different products or batches.

Interchangeable filling nozzle

The gross bagging scale WBE 25 can fill both open bags and valve bags. Specific filling nozzles are available for this purpose, which can be exchanged using a quick-change system.

- When filling open bags, a pneumatic bag clamp ensures a secure hold and low-dust filling.

- A clamping device and inflation function are integrated for valve bags to ensure that the bag remains securely in place during filling.

This concept supports businesses that regularly switch between different types of bags or materials. Different bag materials – such as plastic, paper, or composite materials – can also be filled.

Secure sealing of filled bags

Two technologies can be used to seal the bags:

- an impulse sealing device for plastic-based bag materials,

- or a hand sewing machine, which is particularly suitable for paper or woven bags.

Both systems are height-adjustable and can be adapted to different bag sizes.

Fields of application for bagging scales

The gross bagging scale WBE 25 is designed as a universal solution for medium filling capacities. Typical areas of application include:

- the plastics industry (granulates, additives),

- food production (e.g., flours, sugars, starches, milk substitute powders),

- the chemical industry,

- the building materials and animal feed industry.

ATEX- and FDA-compliant versions are available on request, allowing the system to be used in potentially explosive atmospheres or hygienically sensitive processes.

Advantages at a glance

- High flexibility in terms of material, bag type, and dosing system.

- Compact size, allowing the system to be integrated into existing process lines.

- Easy to use, including recipe management and easily accessible replacement components.

- Balanced performance class for medium-sized productions.

Positioning in the market environment

While fully automatic high-performance systems are often designed for maximum speed, standardized packaging formats, and largely automated processes, the gross bagging scale WBE 25 is positioned in a segment where versatility and controllable process steps are more important than peak performance.

This makes it suitable for companies that fill different products, operate seasonal or batch production, or where convertibility and ease of operation are paramount. The system also offers a pragmatic approach for companies that want to avoid excessive automation for economic reasons.

Result

The gross bagging scale WBE 25 from HUZAP is a robust, practical solution for medium output ranges. It combines compact design with variable dosing and bag options, making it particularly useful where heterogeneous materials and changing packaging requirements occur.

It does not replace large high-performance systems – but it doesn’t need to. Its strengths lie in its flexible range of applications, controlled dosing and weighing technology, and the ability to reliably process different materials and bag formats.