The pallet is place on the roller conveyor by a lift truck, so it’s necessary to design a static weighing system that takes into account any dynamic stresses caused by impact.

Our solution

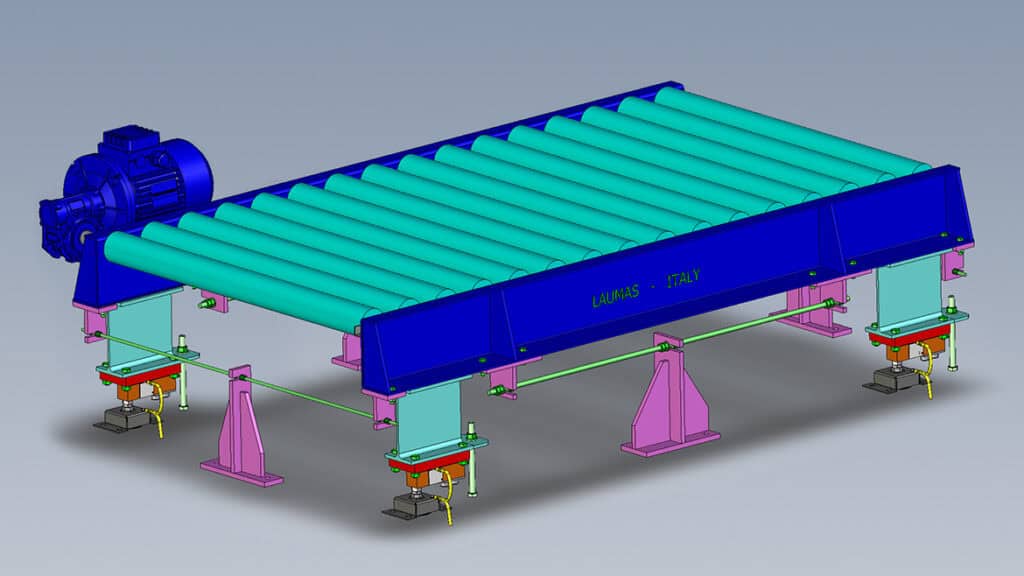

The system consists of:

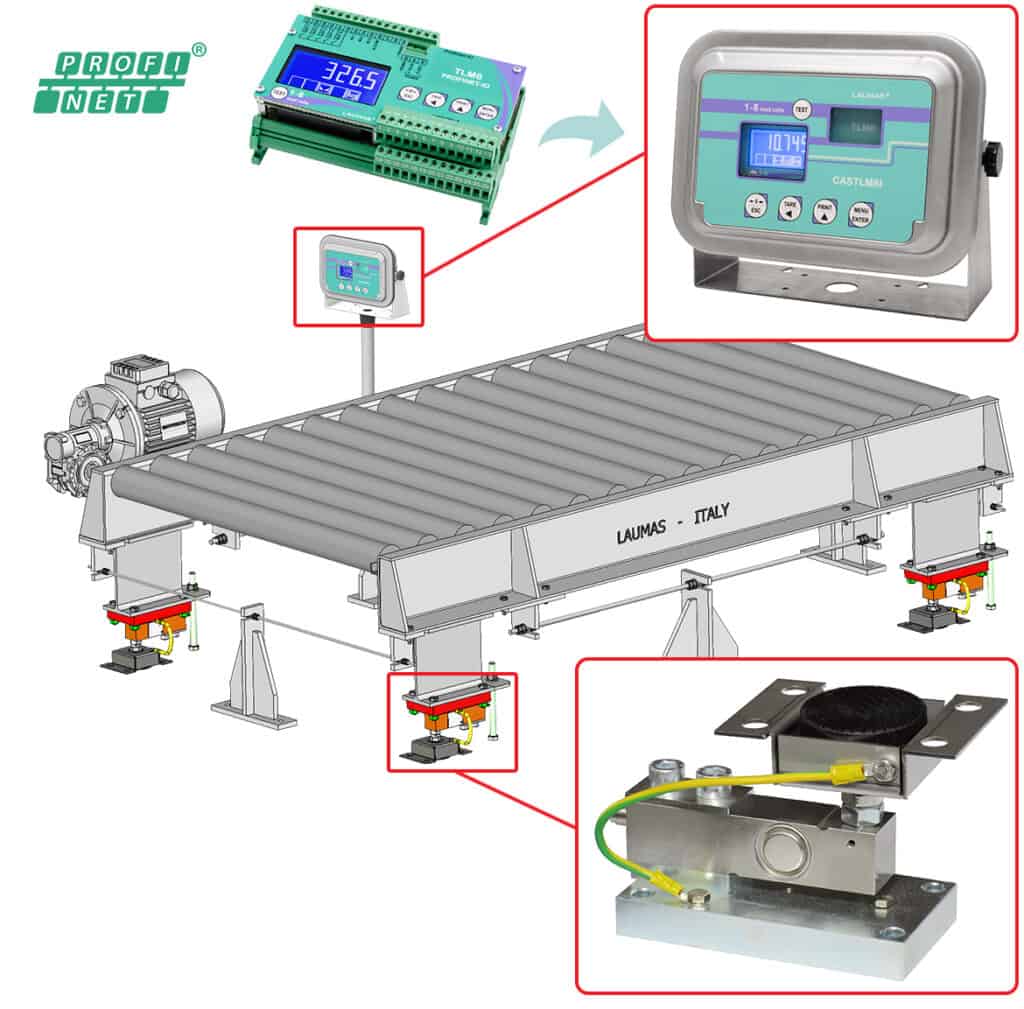

- 4 FTP 2000 kg shear beam load cells, located under the feet of the roller conveyor;

- 4 PV mounting kits with balls inside the feet and an anti-tilt system;

- 1 TLM8 Profinet IO weight transmitter in an IP69K stainless steel box;

- 4 threaded rods of approximately 50 cm, constrained to the floor and with the 2 ends constrained to the weighing structure.

How does it work?

A motor and a photocell are also mounted on the structure. A forklift truck rests the pallet on the motorized roller conveyors, which allows the pallet to slide to the point where the photocell is located.

When the pallet passes, the photocell is obscured and stops the system. The pallet is thus located in the middle of the structure, right at the exact point where it is going to be weighed.

This is the moment when static weighing takes place and the measured weight is transmitted to the PLC via the Profinet fieldbus.

Once the weight has been recorded, the PLC instructs the system to restar.