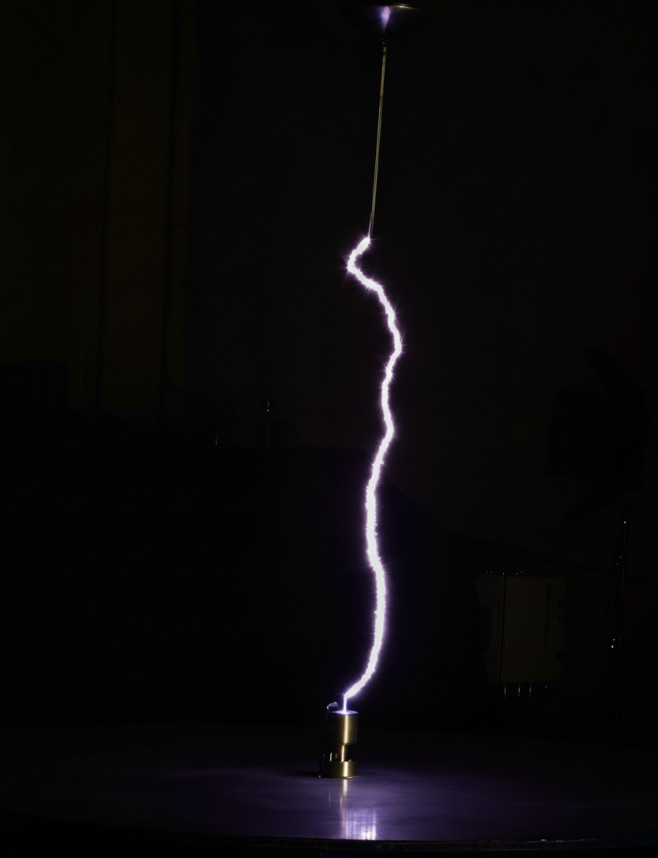

Thanks to our close collaboration with customers, at UTILCELL we have taken innovation a step further by conducting electrical discharge tests in specialized laboratories. Our analog and digital load cells, as well as our electronic weighing systems, were subjected to tests simulating both direct and indirect lightning strikes, verifying their performance under extreme conditions to ensure maximum safety, precision, and reliability.

The aim of these tests was to reinforce and demonstrate, in a controlled laboratory environment, the effectiveness of our lightning protection technology. This technology has been integrated for over a decade in our load cell models 730, 730D, 740, 740D, and in our MATRIX II, SMART, and SMART D electronics.

The results confirmed that our solutions maintain their safety, stability, and functionality even under high-intensity electrical discharges. The tests validated that our weighing equipment can withstand discharges of at least 60,000 amperes, which is twice the average lightning current estimated at 30,000 amperes according to IEC 62305 standards.

The robustness and transparency of the results are supported by the official report “Test Number: 2524-D – High voltage and high current tests on load cells and weighing indicators”, which certifies the testing process.

With these tests, we reinforce our commitment to safety and innovation, offering our customers equipment capable of ensuring reliable performance, reducing risks, and minimizing maintenance costs, even in the most demanding industrial environments.

At UTILCELL, we continue working to ensure that every product combines advanced technology, top quality, and maximum protection.