Kalkwerke Oetelshofen GmbH & Co KG mines the raw material in the Osterholz quarry in Wuppertal-Hahnenfurth and has highly efficient lime kilns. Lump lime or limestone powder can be transported directly from the kilns to the customers via a rail network. W&M approved processes are essential for billing procedures. For safety reasons, it is also important that the wagons do not exceed a certain target weight. Therefore, Kalkwerke Oetelshofen have their own railway scales, which were recently replaced by SysTec partner Waagenbau Dohmen GmbH with a larger scale (15 m long) and upgraded with the SysTec IT8000E weighing terminal. The railway scale is approved as non-automatic weighing instrument (NAWI).

Key facts

- Underfloor railway scale for static weighing of rail vehicles

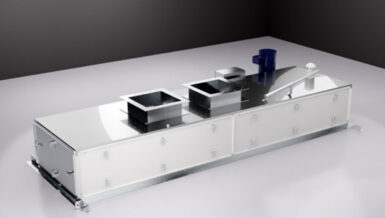

- Electromechanical scale base and SysTec weighing terminal with weight display, data memory and interfaces

- Weighing capacity: Up to 100 t, accuracy class III, W&M approved

Products

- IT8000E: robust and versatile SysTec weighing terminal for continuous operation

- Underfloor railway scale design, assembly and service by Waagenbau Dohmen GmbH

- Software: customer-specific-programming of the SysTec weighing terminal

Installation process of the weighbridge

Due to a new purchase of wagons by a customer of Kalkwerke Oetelshofen, the existing scales were 1.25 m too short for the longer wagons. Therefore, the existing weighbridge had to be replaced and the weighing pit extended. Due to the complicated installation situation under a loading system, the existing weighbridge could not be dismantled using cranes. The weighbridge had to be lifted using hydraulic presses and placed on cross beams. These cross beams rested on several heavy-duty rollers. With the help of these heavy-duty rollers, the weighbridge could be pulled out from under the loading station and pushed to the crane ready for loading. The crane was then able to load the old weighbridge and later lift the new weighbridge into the track bed.

Customer benefits

- The SysTec IT8000E weighing terminal transmits the weight values to the existing ERP system via PROFINET

- Robust SysTec weighing electronics for harsh environments (IP69K)

- W&M approved for billing processes

- High operational reliability

- Durable and low-maintenance scale design

- Smooth replacement of the old rail scales with a larger scale designed for longer wagons

Weighing terminal IT8000E

- W&M approved as non-automatic and automatic scale, (approved in EC, USA, etc.)

- Universal use: Numerous standard application programs

- Customizable: Free programmability

- Robust: Stainless steel housing (ingress protection IP69K)

- High ease of operation: Bright TFT color display 5.7“ with wide viewing angle and large weight display; alphanumeric keyboard

- Numerous interfacing options: 2 internal and up to 6 external scale connections, can be integrated into PC networks via Ethernet or wireless LAN, connection to label & network printer, PLC connection via fieldbus

- Ex-area: For hazardous areas SysTec offers the version IT8000E Ex2/22 and for zones 1/21 the version IT8000Ex

- Several housing options: Wall-mount / desk-top version as well as version for panel-mount installation

- High operational security: Powerfail-safe data storage, password protection, battery-backed real-time clock, remote diagnosis