Material handling solutions supplier ENTEK is poised to execute on a new growth strategy for 2025 and beyond, backed by the full global resources and support of its parent company.

Expanded capabilities for ENTEK in 2025 include building and installing liquid and mechanical systems while leveraging a dedicated project manager and additional engineering support staff. The company’s extensive experience in difficult-to-move materials is extending into titanium dioxide – a costly and notoriously hard-to-handle material.

Finishing the year on a high note, with several truckloads of special-built equipment shipping to customers in various industries, ENTEK is switching gears to accept even more orders in the coming years. “The business unit plans to augment staff with new highly technical sales engineers covering the U.S.”, said Rick Buschini, vice president of material handling.

Difficult Materials Moved Easily

ENTEK’s material handling systems for plastics and other materials ranging from minerals to wood are growing in scope to run the gamut of pellets, powders and liquids.

The growing ENTEK teams can deploy resources to make building a plant or buying equipment solutions “an even better experience” for customers in many industries – in a highly personalized one-stop-shopping experience.

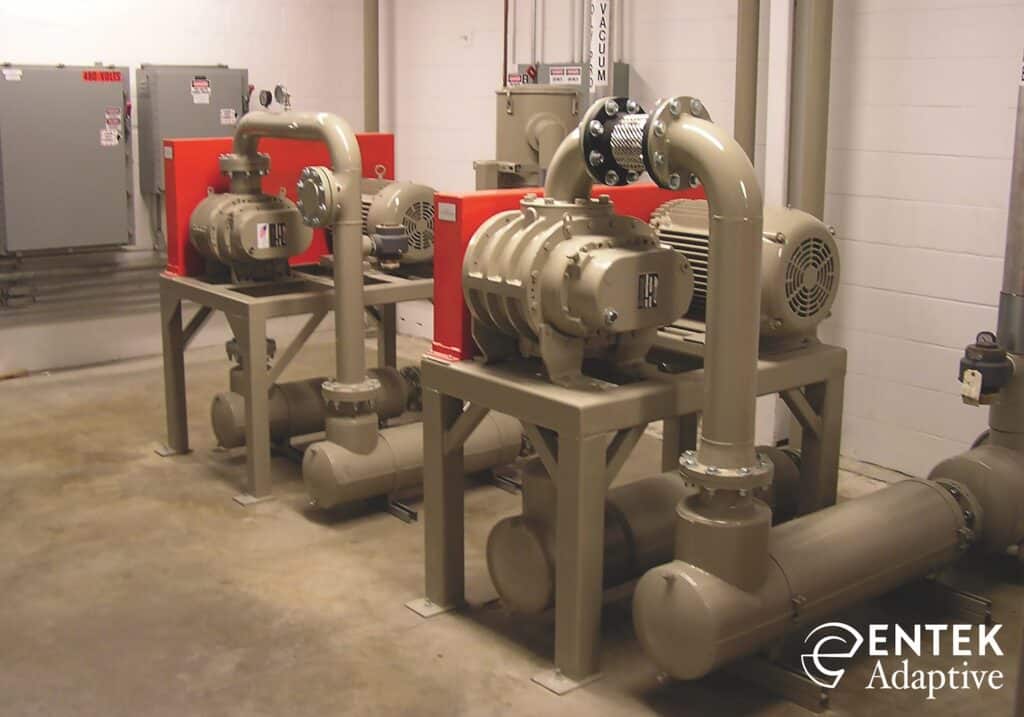

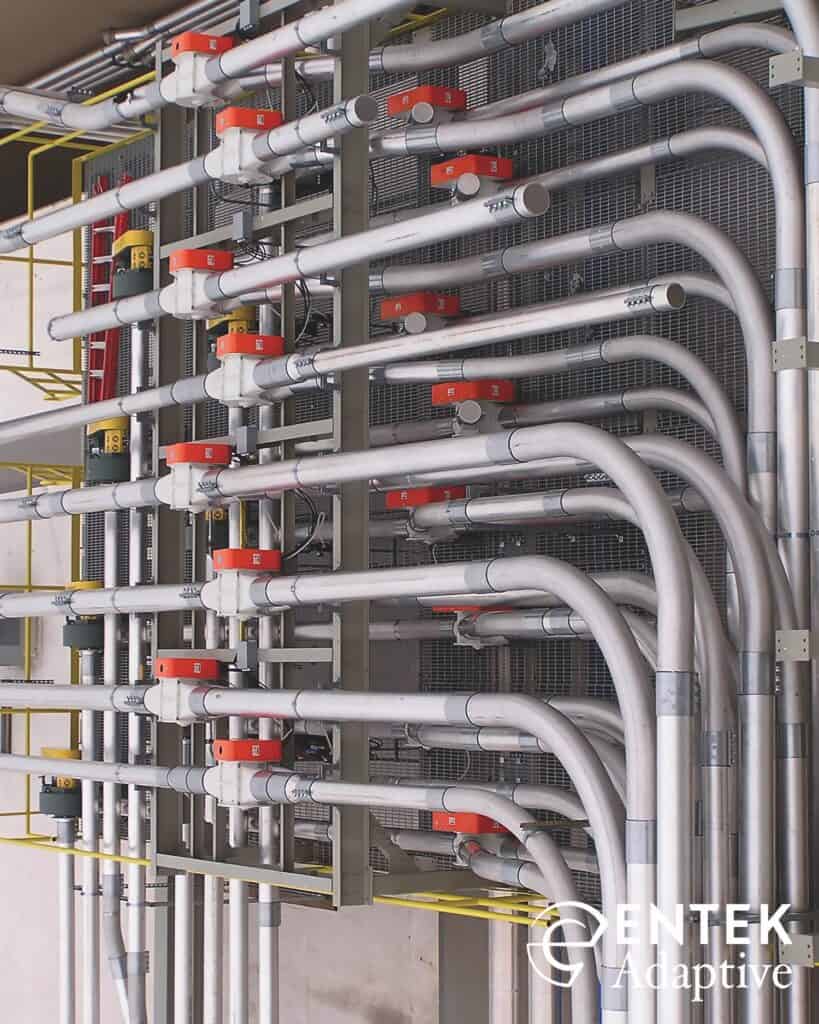

“We have the capability to build all our own equipment,” Buschini explained. “We build all our own blower packages, vacuum loaders, filter receivers, vacuum chambers, supersack unloaders, bag breaks, bins and hoppers. We also build dust collectors up to 10,000 CFM. When we visit a customer’s site, we draw up exactly how their system can look – whether it is new or a retrofit. This allows the clients to modify while we are visiting to ensure we exceed their expectations. We can design your electrical power and structures, and we build our own UL panels. We even have our own installation crews.”

ENTEK Adaptive specializes in multiple materials, including:

• PVC: Offline compounding, including blending, weighing and batching to machines. Applications range from pipe to billboard materials using a single-screw extruder.

• Minerals: This includes drop-in components for utility boxes made of calcium sand and liquid plastic, then solidified with a hardener to prevent breakage. Minerals also are used extensively as filler in packaging.

• Titanium dioxide: Adaptive customers are typically making masterbatches using titanium dioxide powder. Like carbon black, titanium is a messy material that needs to be properly handled and conveyed.

• Regrind: Waste trimmed from products like takeout trays is processed for reuse at 2,000 to 30,000 pounds per hour. These systems are fully automated and do not require moving of gaylords – reducing labor by utilizing storage bins and silos.

A Productive Partnership

ENTEK Manufacturing acquired Adaptive Engineering & Fabrication, based in Placentia, California, in 2022 after over 15 years of collaboration between the two companies. ENTEK Manufacturing also specializes in twin-screw extruders and wear parts, and over the years collaborated with Adaptive to supply integrated material handling systems for complete extrusion systems. Together, ENTEK and Adaptive have formed a single integrated company to share knowledge and resources.

“We’ve got the full support of a huge team, and we can take on whatever solutions our customers need,” Buschini concluded. “We’ve built our engineering and fabrication infrastructure to help customers who have seen their engineering and support staffs shrink. We have the infrastructure to grow on the national and regional level.

“With greater access to engineering and project management support staff, we can run your projects better and address all your needs – beyond just material handling.”