Scaling New Food in Europe

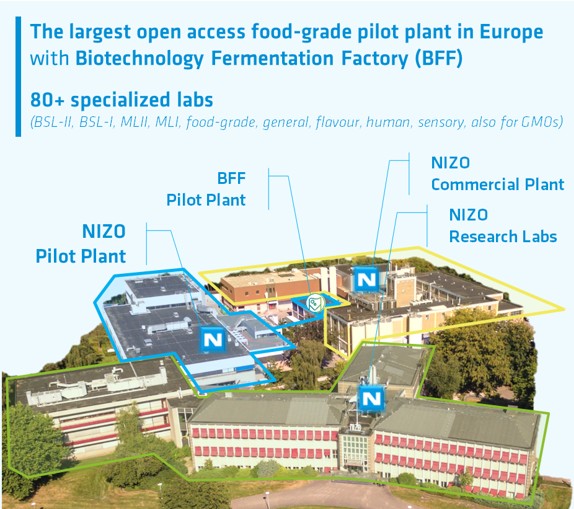

- Contract: GEA will deliver and commission a precision-fermentation upscaling line for BFF (NIZO Food Innovation Campus in Ede, Netherlands).

- Timing: Installation in 2026; pilot operations from 2027

- Impact: Provides the missing middle where innovators validate under food-grade conditions and move faster toward first commercial orders

Frederieke Reiners, Vice President New Food, GEA: “Open-access capacity is the critical development link many innovators have been missing. By delivering BFF’s line, we help teams validate their processes faster under food-grade conditions – and as the logical next step from our GEA New Food Appliction & Technology Center (proof-of-concept) this pilot environment enables application-ready material and decision-grade data sets that de-risk the move toward commercial manufacturing. It also advances Mission 30, where biotechnology meets scalable industrial production.”

Marcel Oogink, Managing Director, Biotechnology Fermentation Factory (BFF Ede), said:

“Our aim is straightforward: to give the industry dependable open-access capacity to validate processes under realistic, food-grade and scalable conditions. With GEA supplying this line, companies will gain the technical reliability and speed they need to move confidently from lab development toward industrial readiness.”

Closing the missing link with an open-access model

Many precision and biomass fermentation projects stall between lab proof-of-concept and the first commercial investment decision. BFF’s model addresses this gap with a single, coherent validation environment that de-risks tech transfer, accelerates time-to-validation and supports Europe’s move toward biotechnology-enabled food production.

BFF operates as an open-access facility, offering a bookable fermentation upscaling capacity, process expertise and quality procedures to run pilot campaigns and generate decision-grade data without the need to build a facility of its own. Operating under food-grade standards, BFF produces trial volumes suitable for sensory evaluation and application testing, giving product teams material they can use in subsequent end-product development.

Capacity and integrated workflow that support credible decisions

Anchored by both a 1,000 liter and a 10,000-liter main fermenter, GEA is delivering an integrated upstream-to-downstream line for food-grade operations – from media preparation and controlled fermentation to cell harvest and a filtration train for recovery and polishing – with commissioning and validation support to produce decision-grade data sets while keeping organisms, recipes and commercial figures confidential.

This setup complements BFF’s existing pre-pilot assets and its biomass fermentation lines and directly connects to the downstream processing (DSP) pilot plant at NIZO on the same campus. Teams can run fermentation, primary recovery and professional-scale concentration and purification in one place. Together, this creates one of Europe’s most complete mid-scale, food-grade validation environments for precision and biomass fermentation.