Achieve uniform sampling across powder types with customer auger designs

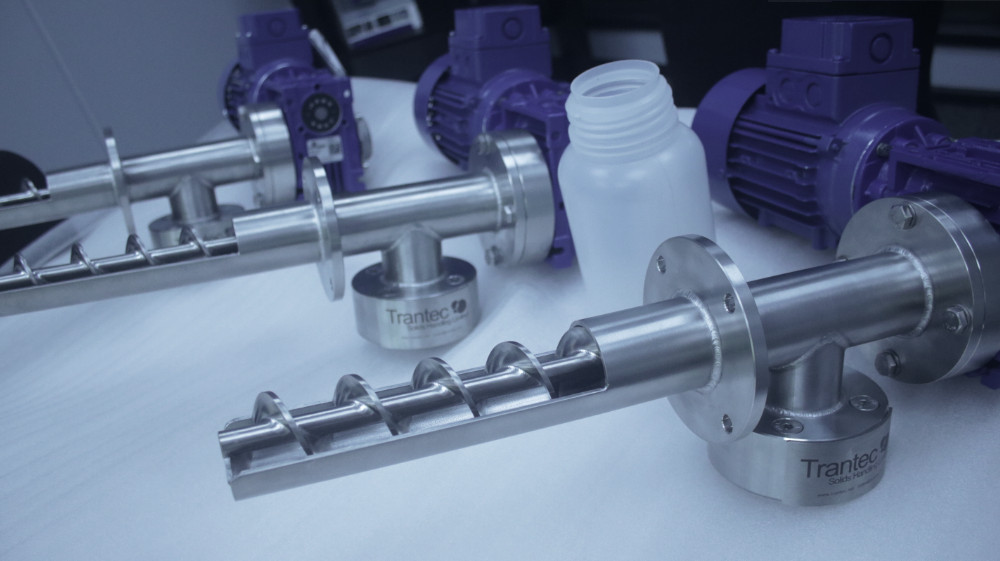

At the heart of Trantec’s innovation is versatility. Recognising that not all materials behave the same, Trantec, through its specialist division Augers UK, offers a wide range of interchangeable augers precision-engineered to meet the demands of specific materials, designed to handle everything from free-flowing powders to sticky, cohesive, or fine particulate substances. Their knowledge of material characteristics allows them to create augers that perfectly align with specific material types. For example, Free-flowing powders such as granulated sugar, salt, or dry milk perform well with augers that feature uniform pitch designs. Whereas sticky or oily materials like cocoa powder or whey protein are better handled with variable pitch or tapered cores to maintain flow and reduce blockages. Their vast knowledge of material characteristics and auger design capabilities also allows them to produce augers capable of handling materials with variable and vast characteristics, even which may contain multiple particle sizes, such as instant soup mixes, protein shake blends, or nutraceutical premixes, ensuring that both fine powders and larger granules are sampled uniformly and prevents product separation during sampling, delivering a consistent and representative sample every time.

Industry-Wide Compatibility in One System

Trantec samplers feature a precision-engineered universal bottle thread system that ensures a secure, leak-free connection with the client’s specific sample bottles. This tailored design minimises the risk of contamination or sample loss during collection, preserving sample integrity. Interchangeable thread inserts enhance operational flexibility, allowing seamless transitions between different bottle types and sizes without the need for additional adapters or modifications. When paired with interchangeable augers, users gain the ability to adapt seamlessly to a broad spectrum of material characteristics. This eliminates the need for multiple sampler units, ensuring reliable performance across a wide range of applications. Whether handling fine powders, cohesive materials, or varying bulk densities, Trantec samplers help manufacturers meet stringent sampling requirements while optimising process efficiency, even in the most demanding environments.

Simplify sanitation with hygienic, tool-free, quick-release sampling equipment that ensures reliable, contamination-free sampling

A standout feature of Trantec’s sampler range is its ease of cleaning. Available with a quick-release mechanism, it enables units to be disassembled in moments without the need for tools. This is vital for industries with strict hygiene standards, where frequent cleaning and minimal downtime are essential.

Whether used in pharmaceutical laboratories or food-grade production lines, the ability to quickly disassemble and clean equipment supports regulatory compliance while minimising production delays. Trantec’s quick-release feature is available across their product ranges, from volumetric and micro-batch feeders to flexible screw conveyors, ensuring seamless integration with your cleaning protocols and production systems.

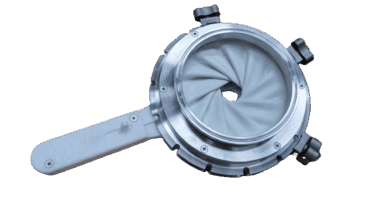

Micro Sampling for Critical Applications

For highly sensitive applications, such as research and development laboratories or pharmaceutical formulation, Trantec offers micro powder samplers that deliver exceptional accuracy even at extremely small sample volumes. These compact systems are engineered to the same rigorous standards as their full-sized counterparts and are ideal for situations where sample integrity must be preserved with absolute precision.

Despite their size, micro samplers offer the same benefits, consistent performance, easy cleaning, and robust construction. They enable laboratories and small-scale production teams to sample with confidence, ensuring that the results accurately reflect the product’s true quality.

Engineered for the Future

With the combination of interchangeable augers, custom-made bottle threads, hygienic features, and micro-sampling capabilities, Trantec’s auger powder samplers are designed for modern manufacturing environments that demand both flexibility and control. When paired with Trantec’s advanced automated control panels, featuring intuitive touchscreens and programmable sequences, these systems offer a seamless blend of reliability, adaptability, and user-friendliness.

For companies seeking to simplify their sampling processes without compromising accuracy or compliance, Trantec delivers a proven solution tailored to real-world needs. With over 30 years of industry experience, Trantec understands the challenges associated with powder processing and offers robust, forward-thinking solutions trusted by industry leaders worldwide. Whether you’re developing a new production line or improving an existing quality control process, our sampling solutions are designed to grow with your business.