These impurities, though often overlooked, directly impact product quality, processing efficiency, and operating costs. Surface blurring in molded products, defects in films and fibers, gel formation, or higher scrap rates are just a few visible consequences. Moreover, dust accumulation inside equipment shortens machine life, raises maintenance needs, and increases the risk of safety hazards.

To overcome these persistent challenges, Indpro has developed and commercialized PelletPurge®, a patented pellet cleaning technology. By integrating PelletPurge® within pneumatic conveying systems, industries can transform their handling operations into a controlled, contamination-free process that maximizes product quality and operational efficiency.

The Problem: Dust and Streamers

Dust and streamers are generated primarily due to frictional interactions inside conveying pipelines.

- Dilute Phase Conveying: At higher velocities, pellets undergo repeated collisions with pipe walls and elbows, leading to breakage and streamer formation.

- Dense Phase Conveying: Though slower, the higher pressure and pellet-to-pellet interactions result in micro-dust and fine contaminants.

- Additional Influences: Pellet geometry, moisture, softening temperature, and conveying air temperature can exacerbate contamination levels.

Once generated, these impurities propagate through the system and concentrate at critical points—feed hoppers, extruder throats, or packaging lines—causing visible defects and hidden processing inefficiencies.

In high-precision manufacturing, particularly in optical clarity films, wire insulation, automotive components, and medical-grade polymers, such contamination cannot be tolerated. This makes inline pellet cleaning a necessity rather than an option.

PelletPurge®: Working Principle

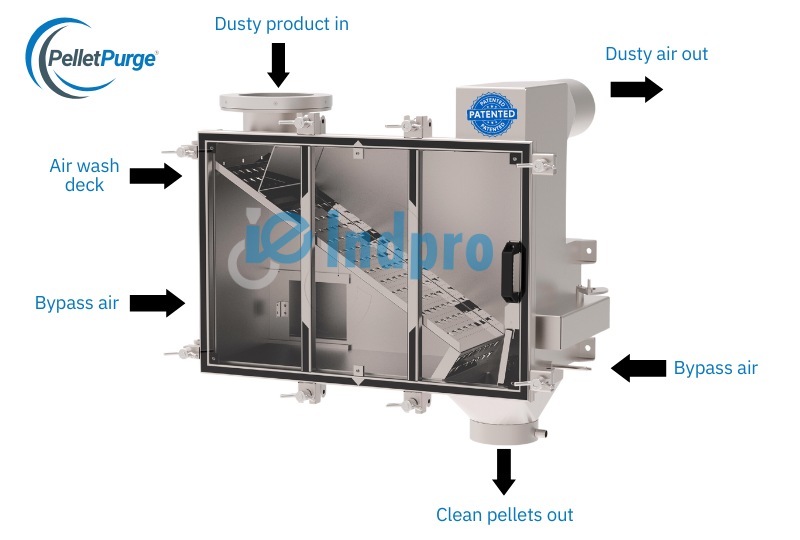

PelletPurge® is engineered as a modular pellet cleaning station that can be seamlessly integrated into a pneumatic conveying line. Its design revolves around controlled air-wash cleaning combined with static charge elimination.

1. Material Entry

Pellets enter PelletPurge® through a controlled inlet valve, ensuring regulated material flow and minimal surges.

2. Static Charge Elimination

Electrostatic charges generated during conveying increase dust adhesion on pellet surfaces. PelletPurge® employs a static eliminator upstream of the cleaning deck, neutralizing these charges and enabling efficient separation.

3. Air Wash Deck

The core of the technology lies in its precision-engineered fluidizing plate, equipped with specially designed slots and perforations. Clean air flows upward through this deck, fluidizing the pellets while dislodging surface dust and streamers.

4. Separation and Discharge

- Cleaned pellets are discharged at the lower outlet, ready for further processing.

- Contaminated air carrying dust is extracted via an exhaust system into a dust collector or cyclone, where impurities are captured before clean air is released or recirculated.

This systematic sequence ensures pellets are consistently purified without mechanical abrasion or material degradation. System Configurations PelletPurge® is adaptable to plant-specific layouts and is offered in two primary configurations:

1. Open Loop System

- Air Supply: Fresh filtered air supplied via a wash-air fan.

- Dust Extraction: Exhaust air with contaminants passes through a dust collector.

- Applications: Suitable for facilities with frequent product or color changes, where risk of cross-contamination must be eliminated.

2. Closed Loop System

- Air Supply and Return: The wash-air fan circulates air through PelletPurge® and back after dust removal.

- Applications: Ideal for standard operations handling similar product grades or when inert gas is required (e.g., oxygen-sensitive polymers).

Both configurations are designed for energy efficiency, low maintenance, and adaptability to varying throughput requirements.

Integration within Pneumatic Conveying Systems

The modularity of PelletPurge® allows integration at multiple points in the conveying chain:

- Central Surge Bins / Day Bins: Ensures clean pellets are available for distribution to multiple processing machines.

- Extruder and Injection Molding Feed Hoppers: Prevents dust-related defects, surface blemishes, or gel formation at the processing throat.

- Packaging Systems: Integrated at hopper outlets before bagging or bin filling to ensure dust-free packaged material.

- Recycling Operations: Cleans regrind or flakes prior to optical sorting, preventing dustinduced sensor blinding.

Such inline integration not only improves product quality but also reduces downstream maintenance and extends equipment life.

Technical Advantages

- Consistent Product Quality: Minimizes defects in films, fibers, molded parts, and extruded profiles.

- Improved Processing Efficiency: Clean pellets reduce machine downtime and enhance throughput.

- Reduced Scrap and Wastage: Prevents burning of fines and streamers in molds.

- Workplace Safety: Lower dust emissions reduce explosion hazards and operator exposure.

- Environmental Compliance: Meets air-quality norms by controlling fine particulate emissions.

- Low Operating Costs: Air-based cleaning with minimal moving parts ensures reduced wear and maintenance.

Capacity and Scalability

PelletPurge® is available in multiple models, ensuring scalability from pilot plants to large production facilities:

These variants allow integration across a wide range of conveying capacities, from niche highpurity applications to bulk industrial-scale operations.

Testing and Validation

To ensure performance, Indpro operates a state-of-the-art PelletPurge® Test Lab. Clients can send pellet samples to conduct cleaning trials under controlled conditions.

The lab delivers detailed test reports, including:

- Dust content before and after cleaning.

- Efficiency metrics for different pellet types.

- Performance under varying air velocities and capacities.

This capability enables customers to validate ROI and optimize configurations before full-scale adoption.

Case Study: Dust Reduction Results

To evaluate the effectiveness of PelletPurge®, a pilot trial was conducted at our pilot testing plant

- Dust Concentration Before Cleaning: 3,631 ppm

- Dust Concentration After Cleaning: 59 ppm

- Reduction Efficiency: ~98%

The trial confirmed that PelletPurge® can deliver significant dust removal across diverse material types, ensuring cleaner pellets and measurable improvements in downstream processing.

Conclusion

In bulk solids handling, especially in polymer and plastics manufacturing, pellet purity is no longer negotiable. Pneumatic conveying will always introduce dust and streamers, but PelletPurge® ensures these impurities do not propagate downstream.

By combining static elimination, precision air-wash cleaning, and flexible system configurations, PelletPurge® redefines how industries approach pellet quality management. Its integration within pneumatic conveying systems delivers clear advantages—higher quality, reduced scrap, lower maintenance, and improved safety.

With capacities up to 10,000 kg/hr & new models under development with capacities upto 150,000 kg/hr, compatibility across multiple materials like pellets, flakes, granules, and a proven test-lab validation process, PelletPurge® stands as a benchmark in product innovation for bulk solids handling.

Indpro continues to innovate at the intersection of engineering excellence and process reliability—delivering solutions that help industries achieve operational efficiency, sustainability, and superior product quality