Video

Vortex Aero-Slide Conveyor for Fluidizable Powders

The Vortex Aero-Slide Conveyor represents a highly efficient air-gravity solution engineered for the seamless transfer of lightweight, fluidizable dry bulk solid powders.

Versatile, Cost-effective and Efficient Material Dosing

The Trantec True-Flow Screw Feeder delivers reliable, accurate, and consistent material feeding, all without unnecessary complexity or high cost. Designed as a simple, efficient, and cost-effective solution, it strikes the ideal balance between performance and value, making it perfect for cost-conscious customers who need dependable dosing and user-friendly equipment, without over-engineered controls.

How to Eliminate Workarounds in Industrial Calcium Carbonate Screening

Calcium carbonate is one of the most widely processed industrial minerals, supporting applications in plastics, rubber compounding, coatings, and construction materials. As specifications tighten and production volumes increase, achieving reliable particle size separation at fine micron ranges has become increasingly difficult using conventional screening technologies.

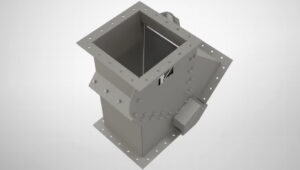

The Vortex® Gravity Vee Diverter™

The Vortex® Gravity Vee Diverter™ from the Quantum Series is designed to replace conventional bucket and flap diverters in gravity flow applications.

Enhance Cleanability and Maximise Productivity with a Trantec QR Tec Metering Screw Feeder

The QR Tec Screw Feeder from Trantec Solids Handling is an innovative solution designed for hygienic, reliable feeding of powders and bulk materials, with a primary focus on ease of cleaning.

Pneumatic Conveying and Industrial Vacuum Solutions in Australia

Companies operating in industries such as mining, manufacturing, food processing and pharmaceuticals increasingly rely on well-designed bulk powder and granular material handling systems to ensure efficiency, safety and environmental compliance.

High-Precision Auger Manufacturing

Augers UK is a specialist division of Trantec Solids Handling, dedicated to the design and manufacture of high-quality augers for a wide range of industrial applications.

Radar Sensors for Complete Inventory Monitoring Systems

The digital transformation of inventory management continues to drive efficiency in the industrial world.

Best Industrial Sieve for Fine Powders

High-value powders demand precision, consistency, and repeatability at scale. As particle-size requirements continue to tighten across industries such as metal powders, additive manufacturing, battery materials, and advanced ceramics, conventional sieving methods are increasingly a bottleneck. Mesh blinding, inconsistent yields, excessive downtime, and frequent maintenance all impact product quality and throughput.

Vortex Orifice Slide Gate Valve for Precise Dry Bulk Flow Control

The Vortex Orifice Gate provides precise material flow control for dry bulk handling systems, designed to address the specific challenges of conveying powders, pellets, and granules.

General Measure AF-50K Bagging Scale – Fully Upgraded Granular Packing Solution for the Fertilizer Industry

In fertilizer production, efficiency and durability are not optional—they are essential. Designed to withstand the harsh working conditions and complex material characteristics of fertilizer applications, General Measure’s AF-50K bagging scale is a fully upgraded granular weigh filler that delivers high-speed, high-accuracy, and long-term stability.

Vortex Seal Tite Diverter for Dust-Tight Bulk Flow Control

The Vortex Seal Tite Diverter is a “flap style” flow control valve for gravity flow applications, facilitating the diversion of dry bulk solid materials like powders, pellets, and granules to multiple destinations.