Research and Markets expects the food processing automation market to reach $45.55 billion by 2033, a significant increase from $24.55 billion in 2024.

With explosive growth on the horizon, system expansion—and optimization—is necessary to keep up with premiumization and fast-paced trends. Implementing level sensors streamlines inventory management by eliminating manual measurements and traditional spreadsheet-based data recording.

But in food production—from meat and dairy to snacks and frozen products—compliance with health and safety standards is of the highest importance.

Non-contact level sensors provide a solution, offering the benefits of automated inventory tracking while avoiding direct contact with ingredients that must be monitored and managed.

Benefits of Non-Contact Sensing

By streamlining processes and preventing cross-contamination, non-contact sensors enhance product quality, reduce waste, and improve productivity.

- Continuous, Accurate Data: Say goodbye to guesswork; sensors measure ingredient levels over time, in storage vessels of many shapes and sizes

- Safer Employees: Workers no longer need to climb bins, tanks, or monitor hoppers to track measurements, keeping them safely on the ground or in control rooms

- Consistent Product: Sensors monitor ingredients during mixing, blending, or milling to ensure precise batch proportions

- Reduced Downtime: Sensors maximize uptime by ensuring a continuous feed of materials and preventing overfills or dry runs

- Low-Maintenance Needs: By avoiding contact with clingy solids, cakey slurries, or sticky liquids, non-contact sensors require less routine maintenance, saving time and reducing CIP labor requirements

- Cost Savings: Balanced labor allocations, proper bulk ingredient ordering, and less out-of-spec product produce an improved ROI

Smart Sensors for Efficient, Contamination-Free Processing

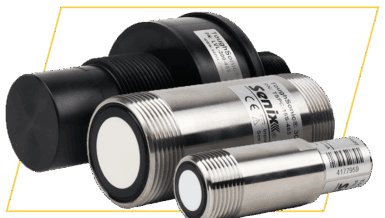

Radar and ultrasonic sensors are well-suited for sanitary applications. Durable construction, proven reliability, and multiple measurement ranges support processing plants with options for level measurement that best fit their budgets and operational needs.

NCR-86 radar features a narrow, 80 GHz beam with accuracy within ≤1 mm.

- Measures tanks and silos up to 393 ft. (120 m)

- Reliable performance in harsh processing conditions including dust, steam, condensation, or humidity

- Best utilized in bulk solid, pellet, powder, or liquid ingredients—such as in flour, sugar, or grain silos

Compact non-contact radars (CNCRs) are ideal in small or medium-sized process or storage vessels up to 98 ft. (30 m).

- Non-intrusive design can be installed through existing openings

- Battery-powered, pigtail-wired, and local display options available

- Wireless, battery-powered CNCR-300 models deliver measurements directly to the cloud, enabling seamless integration into existing monitoring systems

Ultrasonic sensors provide precise, cost-effective liquid-level measurements in ranges up to 50 ft. (15 m).

- Unaffected by optical characteristics of liquid ingredients, such as color or transparency

- Rugged stainless-steel or PVDF plastic housings for harsh processes—including aspects of brewing, pasteurization, and oil production

- Continuous operation in tank level, leak detection, and pump control applications

Hands-Off Labor, Hands-On Analytics

Automating measurements and controls helps workers focus their efforts on higher-value tasks, such as developing strategies for a more efficient, data-driven plant.

Remote monitoring software like BinCloud® gives operators the ability to view inventory in real-time, enabling a variety of in-depth analytics that plants can utilize for lean manufacturing, predictive replenishment, and stronger traceability.

- Anywhere, Anytime Access: Data is available on-site or remotely via a phone, tablet, laptop, or PC—all with one login

- Multi-Site Analysis: View levels in one bin, across one site, or multiple plants as needed; an easily scalable solution for both local and multi-national operations

- Text & Email Alerts: Notify appropriate workers when critical high or low levels are reached, allowing for immediate action

- Strengthened Logistics: Schedule orders, deliveries, or pick-ups for raw ingredients or finished product within the app, gaining complete control over your supply chain

- Robust Reporting: With forecasted usage and historical reports, everyone from supply chain managers to finance planners can view the same data for optimal ingredient stock and cost analysis

- Interconnected Production: Personalized user roles—including parent-child corporate structures—keep data secure and pertinent departments aligned

Helping Manufacturers Maximize Productivity in 2026

Quality, convenience, and flexibility are key within the food, beverage, and milling industries. Non-contact sensors offer the versatility to streamline inventory management, ensure safer worksites, and provide up-to-date data to production and logistics teams.

BinMaster sensors and remote inventory management software deliver comprehensive solutions for smarter, safer food processing operations.