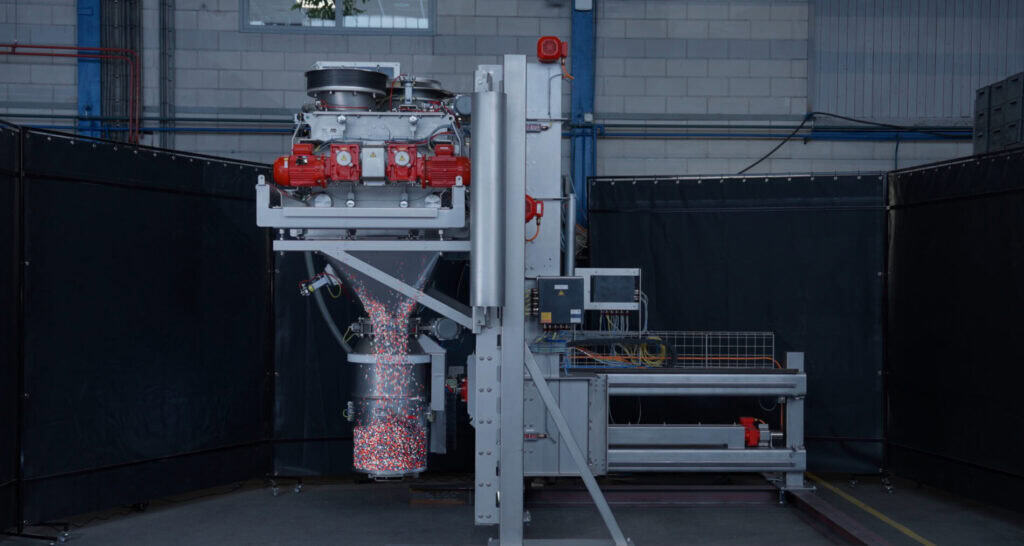

Fully automated mixing in a closed system

The Pegasus® Moving Mixer enables fully automated mixing without any manual handling. The barrel containing unmixed product is automatically lifted, rotated, and connected to the Pegasus® mixer, where its contents are discharged for mixing. Before the process begins, a nitrogen system creates an inert atmosphere, minimizing explosion risks. During mixing, liquids and additives are sprayed evenly onto the product, ensuring homogeneity without waste.

Once mixing is complete, the mixer moves upward and the barrel moves back down, creating space for seamless discharge. The product is returned to the same barrel, without any demixing. This closed-loop process keeps the system dust-free, air-free, and fully hygienic.

Compact, efficient, and easy to clean

Thanks to the unique interaction between the moving mixer and barrel, the Pegasus® Moving Mixer makes optimal use of limited floor space. The system is fully enclosed, easy to access, and highly cleanable. Every detail is engineered for maximum safety, efficiency, and hygiene.

Key features:

- Fully enclosed system for hygienic operation

- Even liquid and additive distribution for consistent results

- Inert mixing environment with nitrogen injection for explosion safety • No manual steps: filling, mixing and discharge are fully automated

- Compact design ideal for tight production setups

A perfect fit for food and chemical industries

The Pegasus® Moving Mixer is ideal for applications in the food and chemical sectors. Especially in environments where safety and hygiene are critical, this system offers an efficient alternative to traditional mixing installations.

As with all our innovations: when standard solutions fall short, we build the one that works.

The Pegasus® Moving Mixer is a clear example of that approach.

For questions or more information, please contact: Rieks Reyers, Sales Manager Dinnissen R.Reyers@dinnissen.com Tel.: +31 (0)77 467 35 55 See how fully automated mixing in compact spaces works.