Packaging & Bagging

Experts for Packaging & Bagging

Doan Pendleton

VAC-U-MAXDoan Pendleton is the President of VAC-U-MAX, located in Belleville, New Jersey. With over 35 years of experience in the design, engineering, manufacturing, and marketing of bulk material transfer systems and industrial vacuum cleaning systems, Mr. Pendleton has developed extensive expertise across multiple industries, including food, pharmaceutical, nutraceutical, plastics, chemical, packaging, and additive manufacturing/3D printing. His technical acumen has driven innovation and operational efficiency, playing a key role in advancing bulk material handling technologies. Mr. Pendleton holds a Bachelor of Science degree in Marketing and Management from Suffolk University.

Robert Meirick

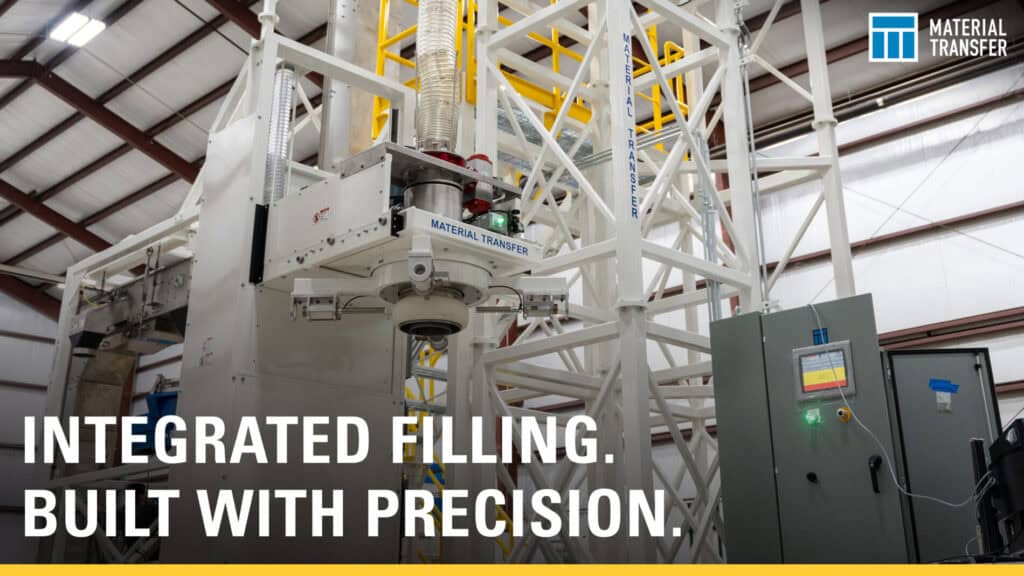

Material TransferRobert brings over 25 years of experience for bulk material handling and material processing equipment to Material Transfer. At MTS, he is responsible to fostering new business opportunities while nurturing account relationships. His depth of experience and industry knowledge allows our Team to meet the growing needs of our customers as we continue to provide the highest quality systems to the marketplace.

George Bougioukas

Acmon SystemsGeorge Bougioukas, Plant Manager of Acmon systems has over a 20 years of experience in plant process design for both mechanical and automation engineering in a wide range of industrial sectors. He has gained a unique knowhow of cross-cutting technologies and applications bringing the organization to reach a new industrial value chain era. George’s expertise includes applications ranging from reception and storage of raw materials, pneumatic and mechanical conveying, sieving, weighing and dosing, mixing, up to bagging and final product dispatch. Behind George there is a dedicated team of engineers who like him are constantly striving to improve design and performance of all plants Acmon systems has been delivering all around the globe for the last 30years on a turnkey basis.

Tim Llewellyn

Flexicon CorporationTim Llewellyn is the Global Director of Sales at Flexicon Corporation, a world leader in the design and manufacture of bulk handling equipment and custom-engineered systems. He has over 20 years of experience managing and delivering complex global projects within the bulk material handling industry, including expertise across multiple sectors, including food, chemical, pharmaceutical, nutraceutical, and plastics. Tim has a proven track record of building and managing teams focused on helping clients solve their powder handling challenges. Tim holds a Bachelor of Science degree in Mechanical Engineering from Lehigh University.

Matthew Bailey – Technical Lead

BFM® Global Ltd.Matthew is a mechanical engineer holding an honours degree from the Auckland University of Technology and has been responsible for BFM® Global’s product development, testing and compliance programme for over 7 years. Matt’s experience is centred on the powder handling industry with a specific focus on flexible connectors, and all the compliance requirements around them. From food to pharmaceutical and all industries in between, Matt works with our Distributor partners, end users and OEMs from Europe, Asia and the Americas to solve application challenges. He regularly attends industry tradeshows around the world and understands the complex requirements of each different market.

Tim Porco

Erie Technical Systems Inc.Tim Porco is the the President of Erie Technical Systems Inc. He oversees the company's day-to-day operations, ensuring top-notch solutions for customer needs. He holds a Chemical Engineering degree from Case Western Reserve University and is an active member of the Flexible Intermediate Bulk Filling Association (FIBCA). With an extensive background in technical sales, product management, and sales management within the powder solids handling industry, Tim applies his diverse skills to develop economical solutions for clients. Tim is committed to listening carefully to customer requirements and translating them into effective applications of Erie Technical Systems equipment.

Chuck Johnson

National Bulk Equipment, Inc.Chuck Johnson is the director of sales at National Bulk Equipment, located in Holland, Michigan. His professional experience includes over 25 years in the design, engineering, & sales of bulk material handling equipment & systems. Johnson holds a BS in mechanical engineering from Michigan State University.

Chris Brennan

Spiroflow LtdChris has been working at Spiroflow for over 10 years and is currently in the role of technical sales manager. He handles all the technical drawings and specifications during the sale and aides our drawing office while the equipment is designed, he also assists the manufacturing department with the build. His vast knowledge of powder handling and mechanical design is why he is involved in every aspect of designing our powder handling solutions.

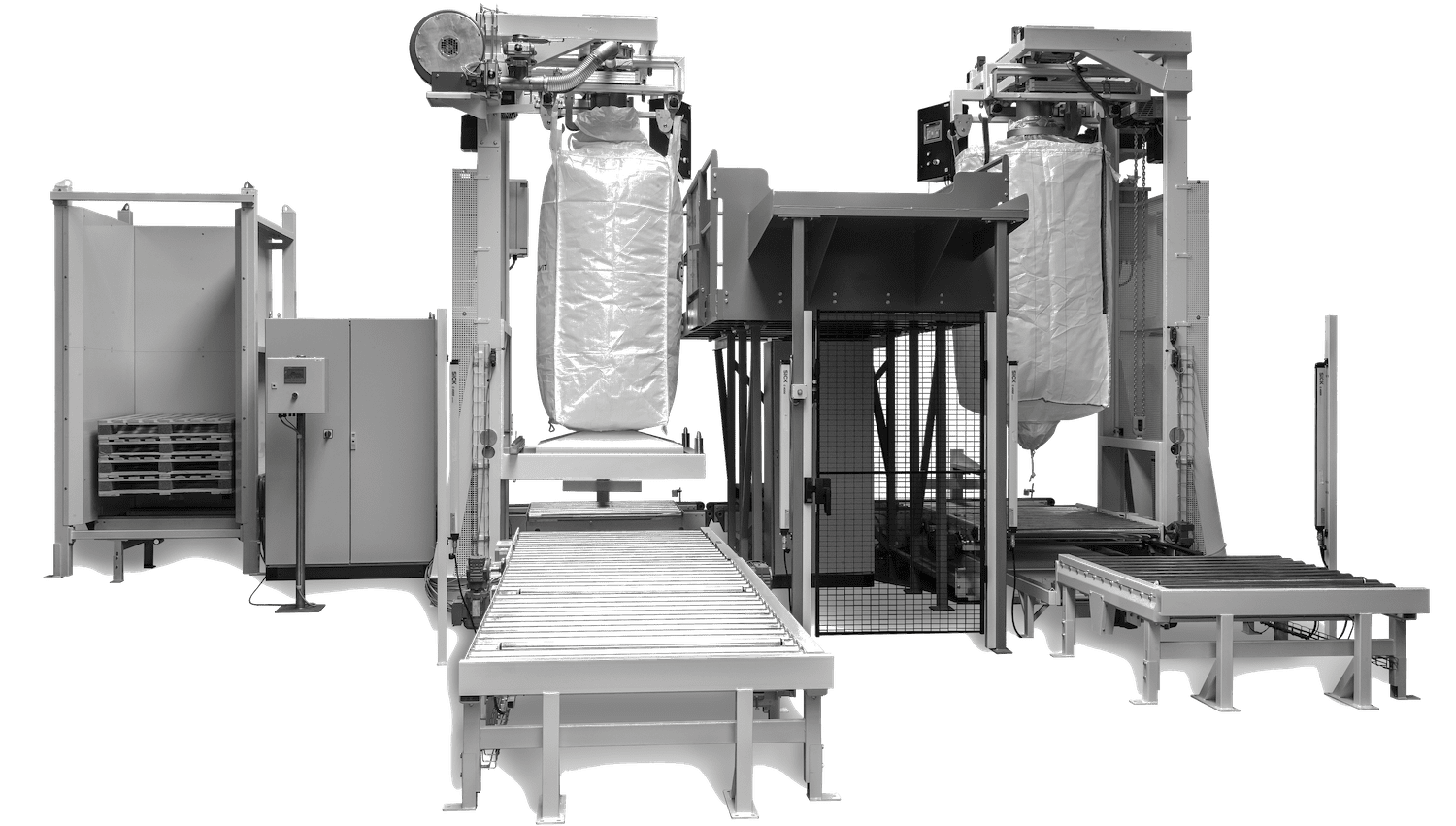

The use of bulk bags has expanded rapidly in recent years as more and more companies with bulk material needs have sought to take advantage of the savings they can potentially offer. There are many different bagging machines using custom configurations to package many kinds of products. These products can range from agricultural products like feed, corn, and seed to chemical and industrial powders like barite, gypsum, and graphite.