As the global cosmetics industry evolves and grows with new styles, trends, and innovations, processed cosmetics must also be modernized.

Powders form a substantial part of the base materials needed for cosmetics.

Cosmetic powders processing requires screening, mixing, milling, drying, and agglomeration technology.

In cosmetic powders processing, it is crucial to effectively and cost-efficiently achieve superior hydrophobic (waterproof) and other material properties and better distribution of active ingredients.

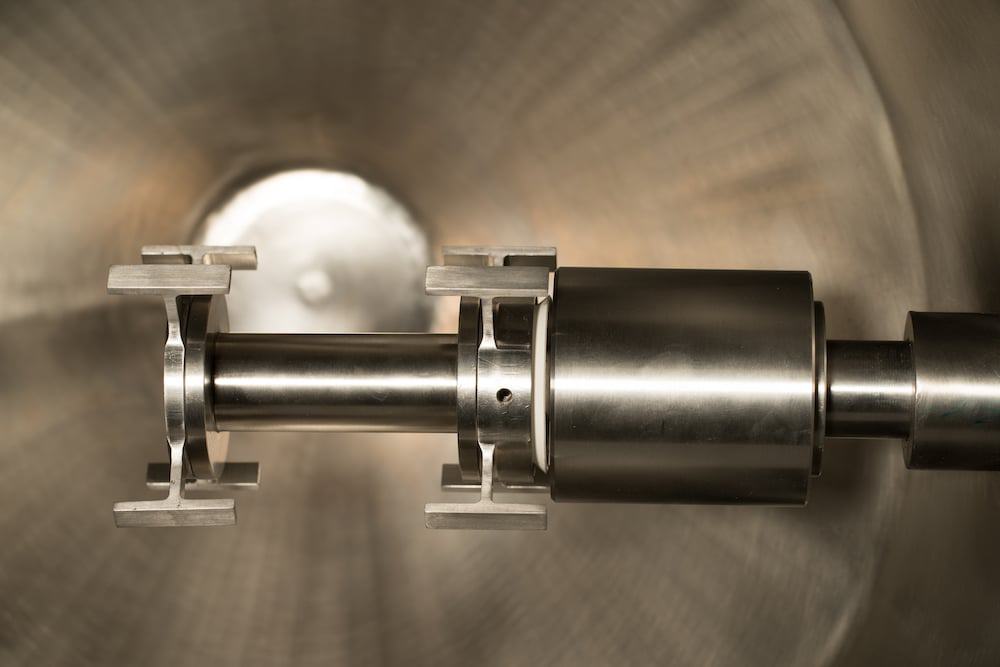

Specialized process equipment is also crucial to effectively blend cosmetic powder and enrobe it in a hydrophobic coating.

While hydrophobic materials are not new in the cosmetics and personal care industry, optimizing the process is essential to create high-performance, powder-based products ranging from makeup and mascara to sunblock.

In manufacturing cosmetic products, precision drying is often required as well.