This article uses the BVP and BVPV air packer systems from packaging machinery manufacturer Greif-Velox to illustrate how equipment can be applied in dust explosion hazard areas, what design and process engineering measures ensure explosion safety, and how these principles are implemented in a real-world industrial application at a starch producer in Denmark.

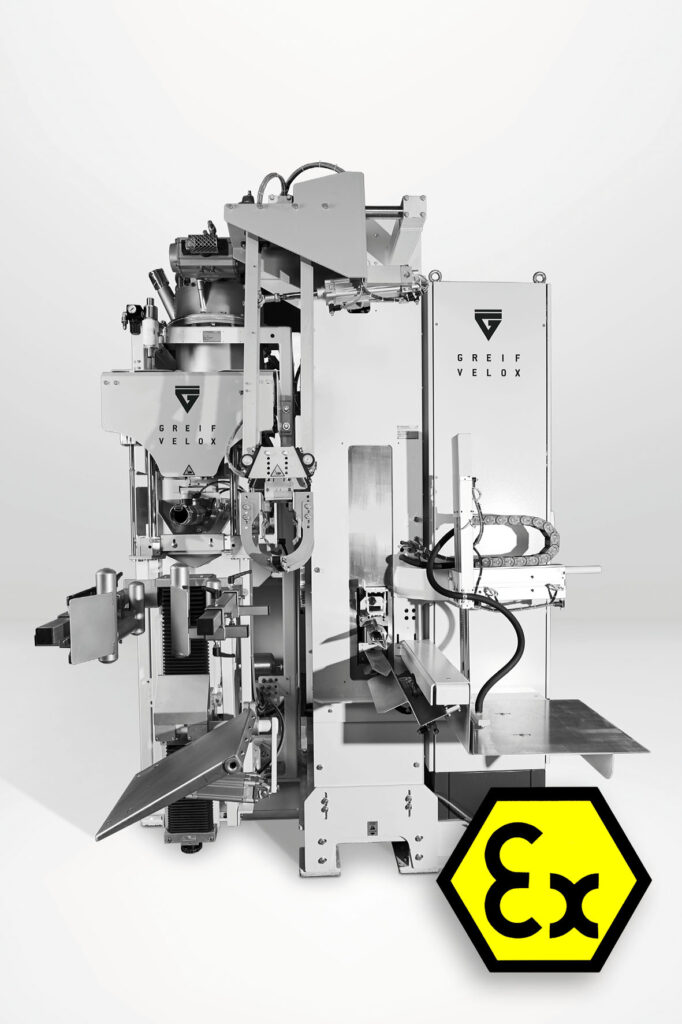

Machine Technology and Explosion Protection Requirements: BVP and BVPV

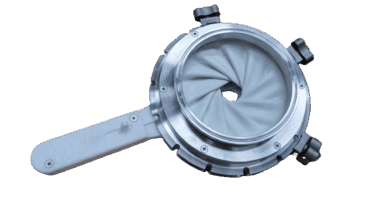

The BVP gross pneumatic packer is designed for powders and fine-grained materials with particle sizes ranging from approximately 30 µm to 5 mm. The BVPV extends the application range to particles from 50 µm to 12 mm, offering higher throughput and optimizations such as reduced residual product discharge. Both systems operate with pneumatic air conveying or air-assisted filling into valve bags (e.g., paper/PE). Dust-reduced filling is achieved through controlled bulk material handling, optimized spout geometry, targeted air supply, and minimized product residues.

Explosion Protection Design

For use in hazardous dust zones—typically Zones 20/21/22 or 21/22—the systems, components, and controls must meet explosion protection requirements, such as those defined by ATEX Category II 3D / II 2D or equivalent standards. Key protective measures include eliminating ignition sources such as sparks, electrostatic discharge, or mechanical friction; maintaining dust concentrations below the Lower Explosive Limit (LEL); limiting ignition energy; and ensuring appropriate dissipation and mechanical safeguards. BVP and BVPV systems can be supplied in dust explosion-proof configurations.

Dust and Process Management

A central focus is minimizing dust exposure around the filling process. This is accomplished using enclosed filling stations with extraction, optimized airflow during the filling process, and a system design with near-zero residue discharge, preventing leftover product that could contribute to explosive atmospheres during material changes. For example, BVPV systems achieve almost complete emptying of the product path. Additionally, the powder flow is designed to reduce bridging and dust buildup—critical for avoiding ignition sources such as smoldering particles or sparks.

Industrial Application – Case Study: Starch Production in Denmark

A practical example comes from KMC (Kartoffelmelcentralen), a Danish starch producer. Based in Denmark, the cooperative has produced potato starch for decades and installed a BVPV air packer line with four filling spouts at its Toftlund site.

This installation addressed several safety and process challenges. On one hand, the use of ultra-fine, modified potato starches with high powder mobility posed a risk of increased dust formation during filling. On the other, bagging malfunctions—such as sticking valve bags—led to product loss, dust exposure, and higher cleaning requirements. To address these issues, the BVPV-4.40 system was configured with specialized air flow design, optimized spout geometry, automatic bag positioning, and an integrated dust extraction system (Aspiration Shield). The result was a significant reduction in airborne dust and stable, reliable filling performance, with up to 800 × 25 kg bags per hour.

From an explosion protection standpoint, all relevant zone classifications were assessed, the machines were fitted with appropriate ATEX markings, and the filling area was equipped with ventilation and dust extraction systems.

Integrated Safety Concept for Explosion Hazard Environments

Designing filling and packaging systems for explosive environments requires a coordinated approach combining mechanical design, process control, and organizational measures. The BVP and BVPV air packer systems provide a robust technical foundation—especially when configured for explosion protection, with systematic dust reduction, material and product handling optimized for minimal dust exposure, near-complete emptying, and a documented risk analysis including ignition source assessment.

For operators dealing with fine powders in Zones 21/22, early involvement of the equipment manufacturer is a critical success factor. With a combination of in-depth consulting and innovative BVP/BVPV system solutions, Greif-Velox supports optimal Ex zone design, ignition source assessment, and validation of dust concentration and ventilation performance—ensuring maximum safety and efficiency throughout plant operations.