This guide explains the benefits of pharmaceutical sifters and how to select the right type for your operation.

Key Benefits of Commercial Stainless-Steel Sifters in Pharmaceuticals

1. Contamination Control and Product Purity

Sifters remove oversized particles, foreign materials, and agglomerates from raw ingredients and finished products. This prevents contamination, ensures only the desired particle sizes move forward, and reduces the risk of costly recalls.

2. Enhanced Process Efficiency

Uniform particle sizes improve mixing, granulation, and tablet formation. Advanced sifters, such as rotary models, offer high throughput and can be integrated into continuous manufacturing lines. Lump removal accuracy can exceed 98%, improving consistency before tablet compression, encapsulation, or formulation.

3. Regulatory Compliance and GMP Standards

Pharmaceutical sifters meet strict Good Manufacturing Practice (GMP) standards. Features like easy disassembly, FDA-approved materials, and precise calibration help prevent cross-contamination. Most are made from 304 or 316L stainless steel, polished to a sanitary finish with gap-free designs for easier cleaning.

4. Operator Safety and Dust Containment

Modern sifters often feature airlock systems and enclosed designs to contain dust, protecting workers from hazardous APIs and maintaining occupational exposure limits.

Types of Pharmaceutical Sifters

The right sifter is critical for contaminant removal in pharmaceutical processes. Common types include:

Vibratory Sifters

These machines use circular or linear motion with a vertical component. Equipped with one or two vibration motors, they are cost-effective for small, single-pass operations (up to ~50 pounds at a time).

However, their vertical motion reduces screen contact time, which can lower efficiency and yield. Vibratory sifters are best for small batches rather than continuous flow systems.

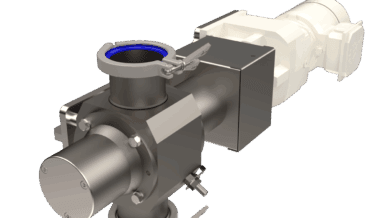

Centrifugal Sifters

Centrifugal sifters use high-speed rotary paddles to break clumps and push material through a cylindrical screen. While effective at lump removal, they can also break contaminants into smaller particles that pass through the screen.

They are less suitable for fragile materials, as the aggressive motion can alter particle size distribution and cause more usable product to be lost to tailings. Frequent screen wear and potential for catastrophic failures require inspections after each batch or daily.

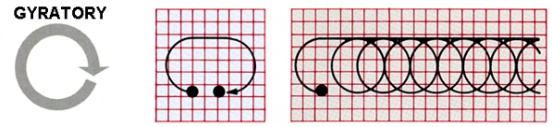

Gyratory Sifters

Gyratory sifters use gentle horizontal motion to maximize contaminant removal while preserving product volume. Multiple screens can be used in a single machine, increasing screening area without increasing footprint.

This method retains material longer on the screen, improving accuracy. Gyratory sifters are widely regarded as the most reliable option for pharmaceutical quality control, with less wear, easier inspections, and higher throughput than other designs.

Sifter Screen Types – Sanitation

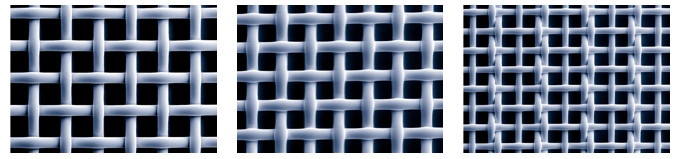

Sifter manufacturers offer market-leading fabric technology in the pharmaceutical industry. The range of materials available includes synthetic (nylon or polyester) and wire (metal mesh) fabrics for efficient screening at each stage of your process. All screen fabrics must comply with current FDA and EU regulations. Common mesh types are depicted below.

NYTAL PA-GG NYTAL PA-MF NYTAL PA-Milling

Commonly, thread types for gyratory and vibratory sifters have wire or nylon mesh sieves with square openings that allow particles to pass through. These screen types are used more frequently than others, as they tend to be sturdier and less expensive. Screen grids, which are less commonly used, have openings that can be round, square, or rectangular, depending on operational needs and quality expectations.

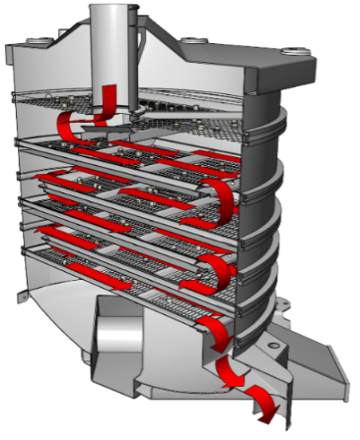

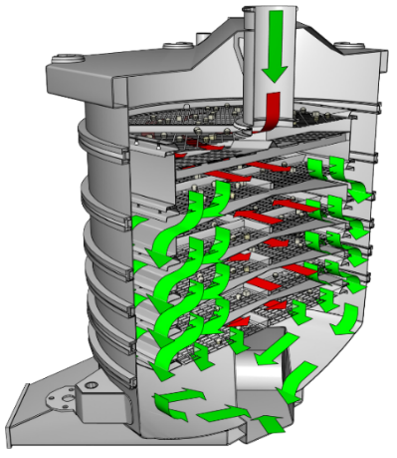

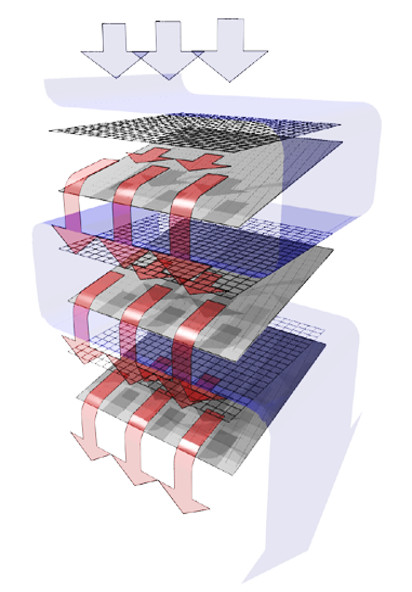

Typically, sieves are stacked with particle openings of gradually diminishing size as the product descends through the sifter (as indicated below). Dry sieving begins with a solid feed, typically powder, that enters the sieve stack at the top sieve. Aided by gravity, solid particles pass through the sieves until they eventually fall onto a sieve screen with openings too small for them to pass through. Finally, the material on each sieve is recorded, and material with the desired particle size range is retained. Other material can then be recycled and re-processed until the correct particle size is achieved. This is depicted below with the purple highlighted flow path.

The flow path in a centrifugal sifter is like the gyratory sifter noted above. In a centrifugal sifter, material is fed into a chamber with a perforated screen on the outside walls. The product is pushed using rotors to the outside screen. Consequently, the larger material is left to carry over while the smaller material passes through the screen as finished product.

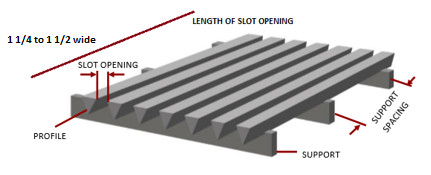

Centrifugal sifters typically incorporate wedge wire-type screen with 1 ¼” – 1 ½” width. Wedge wire screen is a welded screen designed to be durable and resistant to clogging. While requiring a higher initial investment, they typically see a long service life.

As depicted above, wedge wire screens are meant for high-capacity separation on large particles, especially those found in solid/liquid separation. When it comes to small contaminants, this is not the screen of choice. The ability for small particles to pass within these 1 ¼” – 1 ½” wire slots is the number one issue with these types of screens. When it comes to fine separations, woven screen is preferred to wedge wire. While it admittedly has a shorter typical service life, woven screen can offer separations down to approximately 0.005mm vs. wedge wire’s minimum of 0.03mm. For wedge wire, fabrication options are typically limited, due to welding requirements and weight. In contrast, woven wire mesh provides a greater degree of flexibility in fabrication and application.

Screen types in different sifters are highly dependent upon application. Centrifugal sifters typically require the high durability of a wedge-wire or perforated type screen, especially considering that the welded construction is most commonly available in a cylindrical shape. Vibratory and gyratory sifters more commonly use woven mesh screens. While screen mesh depends upon the product in the flow, screen material choice for durability is affected by capacity size and material abrasiveness. For high capacities of finer materials, the gyratory sifter can have over 1,200 square feet of screening area. Careful choice of woven screen mesh can maximize results at this capacity.

Screen Materials

Non-metallic screens have a longer service life and lower contamination risk if damaged.

Stainless steel woven mesh is preferred for oily materials like corn or oats, though it wears faster and can shed small, hard-to-detect metal strands.

Screen wear is influenced by product type, flow rate, and abrasiveness.

Sifter Inspections

Vibratory Sifters:

Require frequent checks for screen tension and blinding. Cleaners are less effective due to limited vertical motion. Inspections usually take under six minutes.

Centrifugal Sifters:

Experience the highest screen wear, making frequent inspections essential—often daily or after each batch. Failures can be severe, and inspections also take under six minutes.

Gyratory Sifters:

Require the least maintenance due to gentle product handling. Drawer-style designs, like the Great Western Qi Series, allow 75% faster inspections of screens, gaskets, and cleaners, improving uptime.

Choosing the right pharmaceutical sifter depends on production volume, material characteristics, and contamination control requirements. Vibratory sifters are economical for small batches, centrifugal sifters suit certain lump-breaking applications but require more maintenance, and gyratory sifters offer the best combination of efficiency, contaminant capture, and ease of inspection.

About Great Western Manufacturing

Great Western commercial sifters are vital in pharmaceutical manufacturing for ensuring product quality, compliance, and operational efficiency. Our ability to provide precise particle separation, maintain cleanliness, and protect both products and personnel makes them indispensable in the pharmaceutical industry.