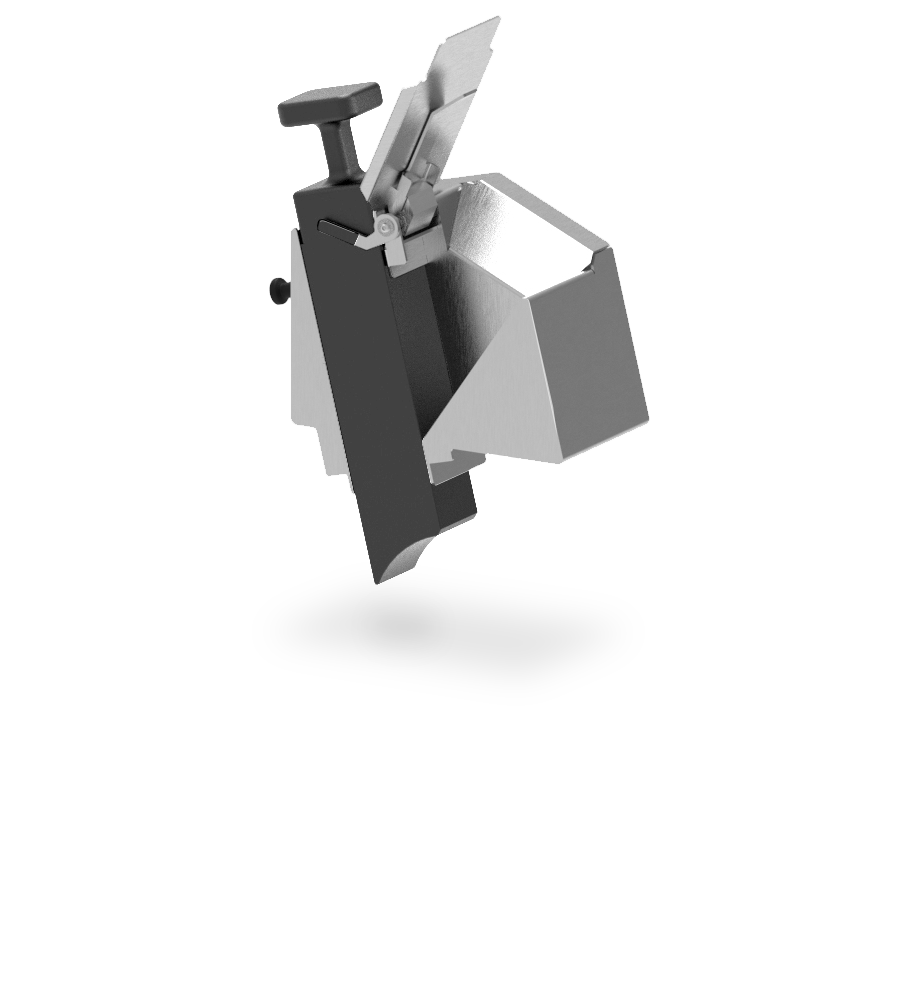

Retsch’s new tabletop cutting mill, the SM 50, available worldwide since April 1st, 2025, offers groundbreaking innovations that set new standards in precision and versatility while minimizing overall process time. Notably, the SM 50 stands out as the only solution on the market when dealing with scenarios where only a handful of sample material is available for the comminution task, making it an ideal choice for situations that demand exceptional adaptability.

Compact yet powerful, the SM 50 integrates seamlessly into virtually any work environment and proves to be a versatile tool for various materials: construction materials, chemicals, fuels, cosmetics, feed, pharmaceuticals, and more.

The newly developed Total Access Concept of the SM 50 forms the basis for rapid and easy cleaning processes. EasyInspect allows access to the entire interior of the mill via a door flap, from the hopper to the collecting receptacle. Full access also means that, for the first time, the entire milling chamber can be effortlessly removed from the cutting mill with just one hand using push-fit technology, enabling time-saving and thorough cleaning under water without residue. The impressive result of the Total Access Concept is unparalleled time-saving potential of a good 30 percent for the entire sample preparation process.

Efficiency and Contamination-Free Processing

Simple and thorough cleaning minimizes contamination risks. The EasyInspect hopper can also be cleaned thoroughly, completing the accessibility to all surfaces susceptible to contamination within the cutting mill. To prevent contamination during the milling process, the SM 50 features an integrated cyclone within the housing for the first time, reliably directing milled material into the collecting receptacle with optimized flow dynamics. This combination also supports the milling of temperature-sensitive sample materials by drastically shortening the milling process.

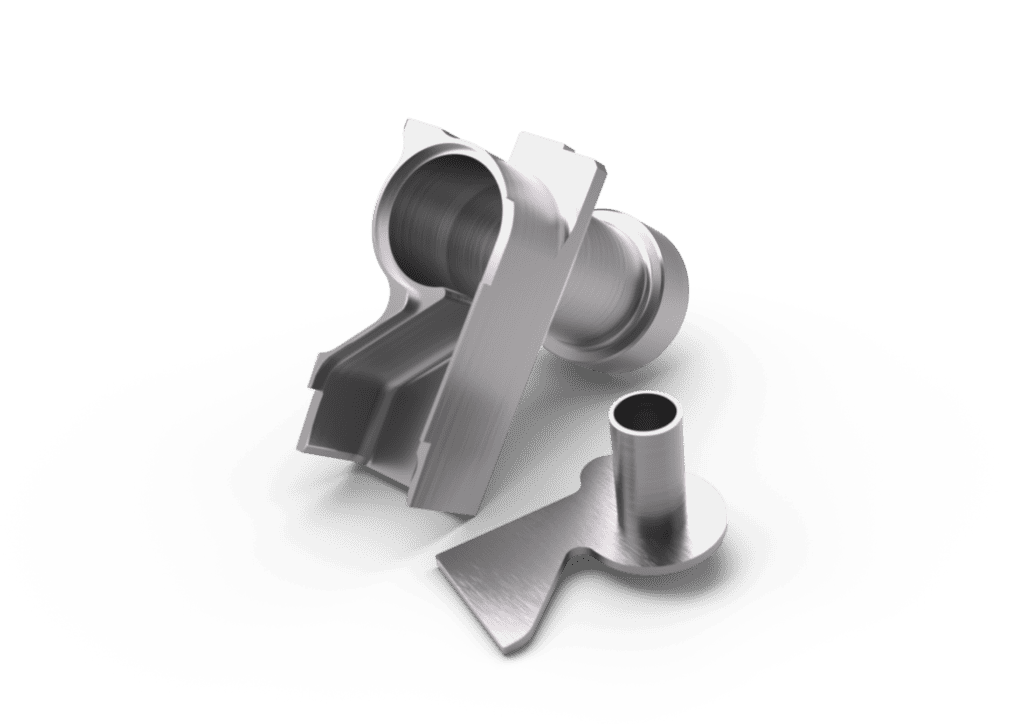

Variable accessories for variable raw materials

Variable raw materials demand adaptable accessories, and the SM 50 provides solutions across a range of industries, including agriculture, recycling, food and feed, and pharmaceuticals. The sieves offer aperture sizes from 0.25 to 10 mm, while collector systems accommodate glass collection capacities of 0.25 and 0.5 liters, along with a 3-liter receptacle.

The integrated cyclone delivers high separation efficiency, eliminating dust pollution and ensuring nearly complete recovery of sample material, even for slightly greasy and sticky substances like animal feed. For dusty samples such as herbs, bark, or dried vegetables, the SM 50 can grind them to particle sizes of less than 200 µm.

Its efficient feed mechanism, utilizing a batch feeding hopper, is designed to handle voluminous, fluffy, and light samples with consistent discharge. Soft materials, including feathers, textiles, or hay, which may significantly change in volume during grinding (becoming fluffy or powdery), are processed reliably and collected almost without residue.

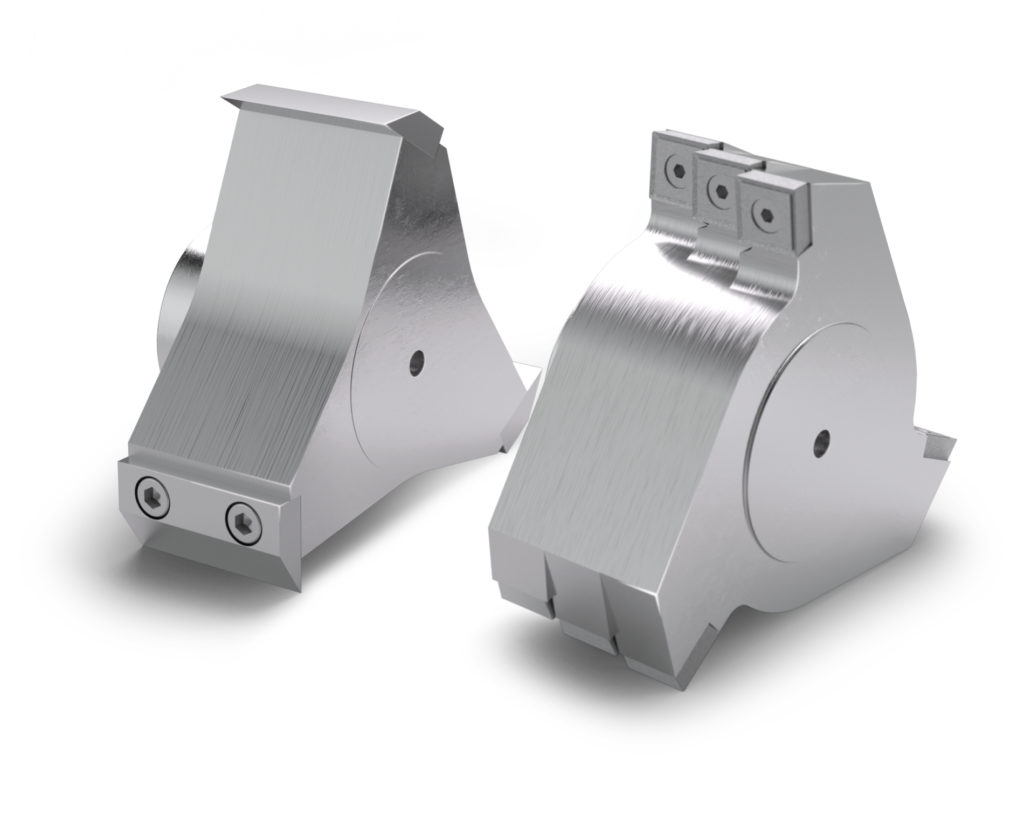

Exceptional cutting performance for tough materials

The SM 50 is a powerful grinding machine designed for efficient processing of challenging materials. Its batch feeding hopper facilitates easy handling of medium-hard, tough, elastic, and fibrous items, such as children’s toys, preforms, wood pieces, and dry dog chew bones. With a robust 1.5 kW motor, the machine can reach speeds up to 4,000 rpm, paired with a rotor diameter of 130 mm, ensuring exceptional high cutting speeds and powerful grinding even for larger pieces up to 50 mm.

Utilizing cyclone technology, the SM 50 swiftly transfers sample materials to the collector, reducing heat buildup in the grinding chamber. This feature helps preserve heat-sensitive materials. Additionally, the machine can employ softer materials, that have been embrittled by freezing, such as withliquid nitrogen to enable to enhance grinding efficiency. These capabilities make the SM 50 versatile and suitable for a wide range of applications.

Ergonomics and Versatile Applications

With its focus on ergonomic design and versatility, the SM 50’s comprehensive offering includes a wide range of accessories that meet the varying requirements of powder and bulk solids industries. The modular concept allows tool-free component exchange, making it adaptable for various applications, especially when different materials need to be processed consecutively. This adaptability makes the SM 50 a true all-rounder, ensuring efficient handling of powders and dry bulk materials with different material properties.

Product Launch provides a chance to win a free SM 50

Additionally, in conjunction with the product launch, Retsch is hosting a global giveaway, where three SM 50 units will be raffled among all participants. Furthermore, every participant receives a prize exclusively provided with the purchase of a new mill.