Thayer Scale’s weigh belt system is designed with a belt conveyor that incorporates an in-process weighing system, enabling continuous process weighing in production before the beans are ready for roasting or packaging.

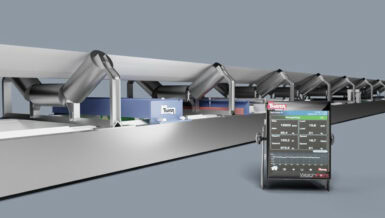

After cleaning, green coffee beans are typically conveyed into storage hoppers based on their origin/variety. Combinations of bean varieties are drawn from these storage hoppers in precise amounts and blended to achieve specified flavor profiles during roasting.

Legacy industrial coffee roasters often utilize a gravity batch system, which consists of a multi-chamber storage hopper, fed by a rotary distributor and chute work system that directs beans to the appropriate section of the storage hopper. The outlet of each chamber features a transition funnel, chute work and slide gate that directs green beans to a common scale hopper. With stack-up heights sometimes as tall as 200ft, process-specific facilities are often required to accommodate these gravity batch systems.

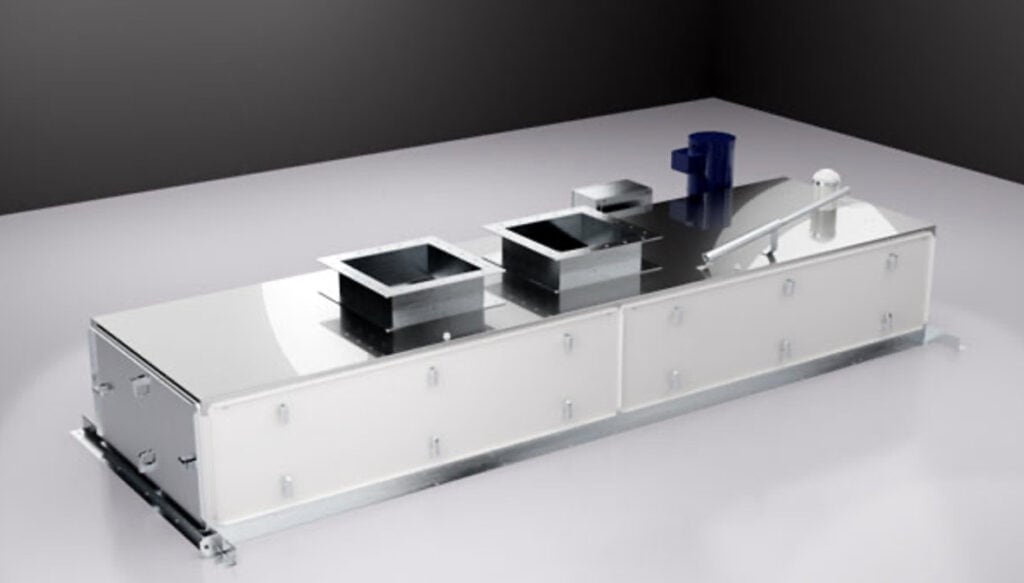

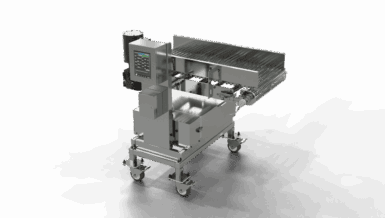

The alternative Weigh Belt-based Green Bean blending system utilized a much shorter green bean storage array consisting of multiple, multi-quadrant hoppers, each fed by multi-position diverter valves. Each pair of silos can discharge onto a common Thayer Scale Model “MWF” weigh belt based on the positioning of slide gates at the bottom of each silo. Each weigh belt delivers high-accuracy green bean blends in a low-profile stack-up that readily fits within today’s building designs. The weigh belt system eliminates gravity chute work and reduces product free fall height, significantly reducing product damage. Gentle product handling maintains higher bean quality and yields larger quantities for the producer.

The weigh belts seamlessly integrate with modern roasting profile software, facilitating automatic, real-time adjustments that mitigate variances in green bean characteristics. Each weigh belt accurately delivers a wide range of batch sizes with a high level of precision, allowing processors to adapt to rapidly changing flavor trends and develop more customized product packaging SKUs for their clients.

Thayer Scale weighing equipment improves inventory control and makes the blending or processing of fragile materials more precise and easier to manage with fewer operators by automating the weighing process.