Years ago, we successfully completed our first project for our customer Fibenol in Estonia and accompanied them from detailed product investigations through comprehensive pre-engineering to the successful implementation of the project.

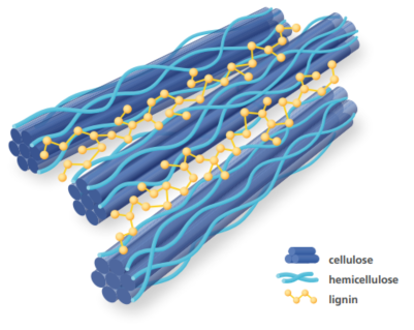

- Industry: production of wood-based raw materials

- Goal: replacing fossil materials with wood-based materials

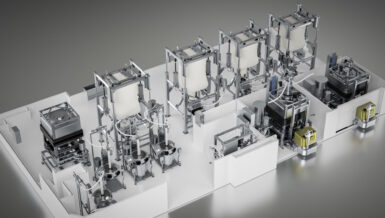

- Solution: plant for processing lignin

The plant converts wood (4 tons of dry matter per hour) into C5 and C6 wood sugars and Lignin. C5 and C6 wood sugars can be used to produce bioethanol, bio-based polymers and for fermentation.

Task Overview

- Product receiving of dried lignin from the on-site dryer

- Pneumatic pressure conveying with rotary piston blower with three-bladed pistons and integrated pulsation reduction

- Dosing into the conveyor line using a blow-through valve

- Pneumatic conveying line over 40 m in silos, product distribution with rotary tube diverter

- Professional design of the silos with bursting discs, CO-measurement mg/m3 air in the silo head space and temperature monitoring over the entire height of the silo cylinder

- Filling with complete big bag filling including pallet dispenser and roller conveyors, with movable big bag docking and calibratable big bag weighing

- Integrated aspiration system for dust-free handling

- Planning, delivery, assembly and commissioning „Everything from one source”

Challenge

The discharge of powdered and ground lignin presents the material handling system with particular challenges due to its “shooting” flow properties. To solve this problem, specific designed rotary valves are installed at the silo outlet before the inlet dosing screw.

Finished lignin products are filled into big bags. This is combined with weighing and dosing in order to be able to record and reproduce the filled amount. The selected rotary valves and dosing screw are controlled by frequency converters to enable rough and fine dosing.

Lignin is a material that required thorough handling procedures to ensure safety during processing. The following three measures are recommended to protect personnel and the plant.

Conclusion

Based on the project, further orders for handling lignin have been won, which are currently being processed. Due to the versatile application possibilities of lignin, Solids is faced with new challenges, in this case “wet lignin” is to be emptied from big bags, conveyed with a pneumatic transmitter and transported to several receiving containers using Puls Pneu Conveying. Thanks to the experience and know-how already gained in the project, this challenge will also be mastered.