Video

Why do I need Industrial Explosion Protection?

Many industries worldwide are exposed to the dangers of dust explosions. Some common examples include: These explosions occur when fine combustible particles, dispersed in air, are subjected to an ignition source within a contained processing environment – for example, a duct, vessel, or dust collector. Ignition can be generated by several factors, including hot surfaces, […]

Active and Passive Explosion Protection Systems

Many industries worldwide are exposed to the dangers of dust explosions in their processing and material handling operations. Food and Beverage, Chemical and Pharmaceutical, Wood Processing and Power Generation are just a few common examples, however there are many more.

Centralized Vacuum Cleaner UFA150EH

Standard Industrie offers a wide range of solutions to address the on-site industrial cleaning requirements. For this, the technical team proposes different configurations to meet the plant needs whatever the industry sector, type of dust and bulk powder material such as cement, gravel, wood chips, coal or food products, … The fixed and mobile vacuum cleaning solutions are designed for the cleaning, recycling and safety of most […]

No More Banging Your Hopper and Bin

The EXEN Air Knocker is an auxiliary device that facilitates the handling of powder and bulk materials. Knocker can EXEN Air support storage, transportation, and supply at various manufacturing sites that handle powder and bulk materials, such as grain or feed silos, flour mills, and cement factories.

No More Scooping, Lifting, Stair-climbing, or Manual Dumping of Food Ingredients

VAC-U-MAX Signature Series™ offer food processors and packagers a quick and easy pre-engineered solution for vacuum conveying powders and granular food ingredients to processing and packaging lines.

Protecting The Production Plant and Employees: Continuous Dust Measurement in Malt Filling

In an Estonian brewery, beer is produced from yeast, hops, malt, and water. Delivered by trucks, the malt is stored in silos before further processing.

New Model EXEN Air Knocker PB Type for your Material Flow Problems

The renewed EXEN air knocker adopts a design and material that minimizes wear of each part during long-term use, and has a structure that can suppress performance deterioration even during long-term use.

Signature Series™ Vacuum Conveying Systems for Powders & Granulars

VAC-U-MAX Signature Series™ vacuum conveying systems consist of 5-parts including pick-up nozzle, convey tubing, vacuum receiver, vacuum producer, and UL-listed controls – for vacuum conveying free and non-free flowing powders, pellets, pastilles and other granular materials, at conveying rates from handfuls to 3500 lbs/hr (1600 kg/hr).

How Reliable Is Your Traceability And Fragment Control For Your Ingredients?

Contamination in one ingredient can compromise the finished product including all ingredients. This can be costly to rectify and lead to loss of productivity and wasted product. Effective traceability and control over all ingredients will reduce the consequences downstream.

Flite-Veyor® Low Profile Drag Conveyor

Given the current product offering in the marketplace, too many manufacturers offer light duty solutions with no regard to longevity or reliability that could meet the needs of our clients' high expectations. Aside from the dimensional features needed for their project, they were also looking for a conveyor that would rest underneath half of the bin floor, then curve up 15° immediately after exiting the bin and discharge into another conveyor, all while allowing chain tensioning to be performed outside of the bin.

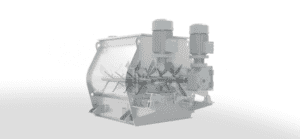

PerMix PFB Dual Shaft Fluidized Zone Mixer

PerMix PFB Dual Shaft Fluidized Zone Mixer. When it comes to aggressive & efficient mixing of products with different densities, yet gentle and no shearing, the fluidized zone mixer is ideal.

ROSS – New Multi-Shaft Video

ROSS has launched a new video featuring the company's line of robust and versatile Multi-Shaft Mixers.