Feeders are typically defined as the link between one process and the next process in a production line. Like extracting / dosing product from a silo or a hopper, or spreading the product to feed the next process in a wide and evenly spread flow. Feeders may also have integrated screens for removing fines or oversizes – or more features for improved product handling or processes (handling, cooling, drying, heating etc). Even inclined vibratory feeding is doable for some product types, if the layout requires so.

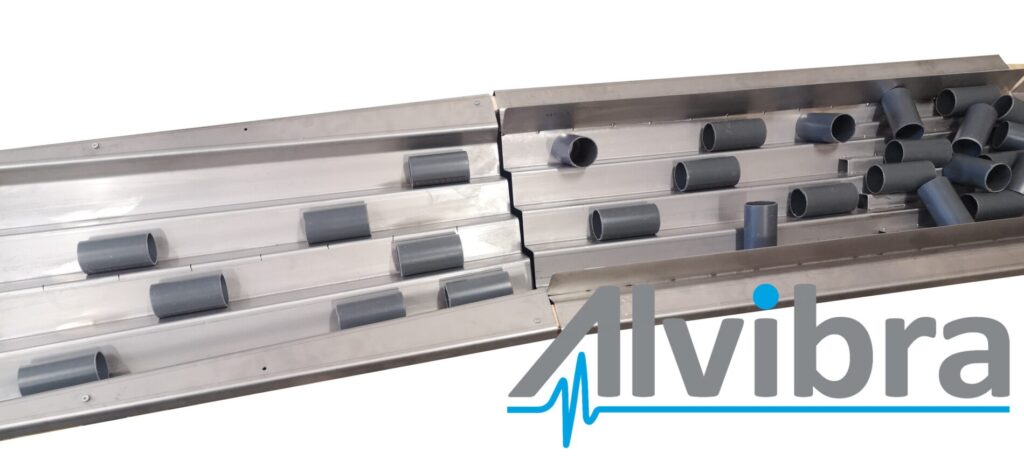

In this above shown case, we receive tubular plastic fittings bulk fed from the manufacturing line, and while feeding those from A to B (right-to-left in above image), the items must be oriented and delivered singulated into several tracks for further handling (eg packing, freezing, coating etc.). While feeding by controlled vibration, several built-in features assist the orientation as well as ensuring that items are delivered with some space in between each item at the desired product speed.

The product could be frozen spring rolls, buns, fresh or frozen vegetables – or for non-food grade solutions, it might be various hardware items, like in this example plastic pipe-sleeves.

Items that do seem similar in shape and size, can however be very different in behavior, why we always consider carefully if tests should be carried out, unless it is a solution done before. Depending on requirements, tests may require several test-stages, adjustments and fabrication of custom shape parts.

The Alvibra test feeders are furthermore typically equipped with flexible vibration technology making it possible to adjust frequency, stroke (amplitude), vibration angle and feeder tray angles.

Adjustable Feeders – by VibraDrive™ or ViFlex™ Vibrator

- Silent vibrator

- Long or short stroke (adjustable)

- Vibrating motion direction (flexible)

- Feeder tray angles adjustability

- Start and Stop instantly

- Easy adjustable speed / capacity

- ViFlex™ Vibrator in Stainless housing

- VibraDrive™ Dual-mass system

Please contact Per Albaek (Managing Director at Alvibra A/S) when you have questions or suggestions.