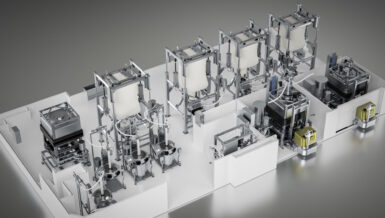

Coscollola Engineering has successfully completed a comprehensive turnkey project for a leading European manufacturer of PVC profiles. The project included the full design, engineering and implementation of a complete raw material handling and dosing system for PVC dry-blend production.

The scope of supply covered everything, from the feeding and dosing of raw materials -including PVC resin, calcium carbonate, stabilizers and processing aids– into the turbomixer, to the pressure conveying of the final PVC dry-blend into storage silos. The installed system is configured to handle 380 kg per batch, with a production capacity of 9 batches per hour.

Key Features of the Installation

The layout comprises a big-bag unloading station for PVC resin, equipped with a crane, automatic filter, and a pressure feeding line capable of 5 tonnes per hour, delivering material into 50-ton storage silos. Additional raw materials such as CaCO₃, additives, and recycled content are received through dedicated big-bag stations.

PVC resin is conveyed and dosed via vacuum to a weighing hopper located above the mixer. CaCO₃ and additives are handled using a gain-in-weight dosing system, also conveyed by vacuum to the same hopper. Recycled material is conveyed into an intermediate hopper and dosed into the cooler through a loss-in-weight system. The resulting dry-blend is then pressure-conveyed to 50-ton storage silos, which feed the extrusion lines.

Added Value for the Client

The solution delivered significant improvements in both efficiency and plant operations. The system enables full automation with recipe management, operated via a PLC control with touchscreen interface. Furthermore, the installation provides complete traceability, minimized powder emissions, and seamless integration into the existing plant layout — all contributing to enhanced performance and workplace safety.

This project highlights Coscollola Engineering’s extensive experience in the design and development of customized solutions for solids handling -including granules and powders- with proven expertise in PVC dry-blend systems across the plastics processing industry.