Understanding the Explosion Hazard

Dust explosions occur when fine particulate matter becomes suspended in air in sufficient concentration and is exposed to an ignition source. Many bulk materials—flour, sugar, grain, powdered metals, and various synthetic compounds—are combustible under the right conditions.

The five essential elements of a dust explosion, often referred to as the “dust explosion pentagon,” include:

- Combustible dust

- Dispersion in air

- Confinement

- Oxygen

- Ignition source

While the first four conditions are often inherent in processing environments, the ignition source is typically the factor that can be most effectively managed—and this is where magnetic separation technology comes in.

Hidden Ignition Sources: Ferrous Contaminants

Ferrous metal contamination in bulk products often comes from worn or broken machinery parts, tools, structural elements, or incoming raw materials. Even small fragments—such as nuts, bolts, nails, or filings—can generate heat through impact, friction, or sparking when they move through high-speed equipment like grinders, sifters, mixers, or pneumatic conveyors.

When a metal fragment is caught in such equipment, it may generate localized heating, mechanical sparking, or even ignition of fine particulate matter. This can quickly escalate into a primary explosion, and in confined systems with suspended dust, can trigger secondary, more destructive explosions.

The Role of Magnetic Separation

Magnetic separators are designed to detect and remove ferrous and, in some cases, weakly magnetic non-ferrous contaminants from product streams before they enter vulnerable processing equipment. There are several types of magnetic separation equipment, each suited to specific applications:

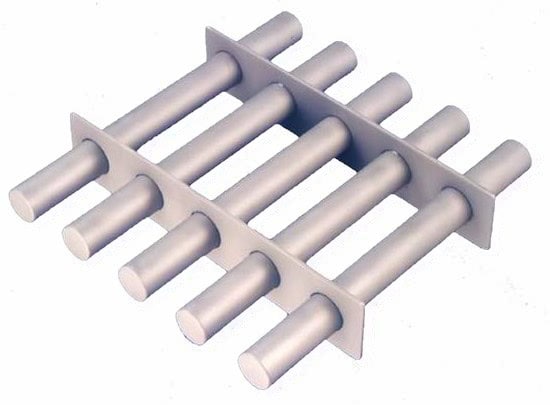

1. Magnetic Grates and Tubes

These are installed in hoppers, chutes, and bins to attract and hold fine ferrous particles from gravity-fed material. Common in food and pharmaceutical industries, they are ideal for intercepting contaminants before they disperse. Grate Magnets are placed directly in the product stream allowing free flowing products to come in direct contact with the grate. Grate Magnets are typically constructed with one inch diameter magnetic tubes mounted on two inch centers in a frame. The length and width can be fabricated to any dimension, usually in two inch increments.

Grate Magnets offer excellent protection from metal contamination. As product flows over the magnetic tubes, captured metal contaminants are pushed to the underside of the tube where they are now out of contact with the product flow preventing washoff back in to the clean material.

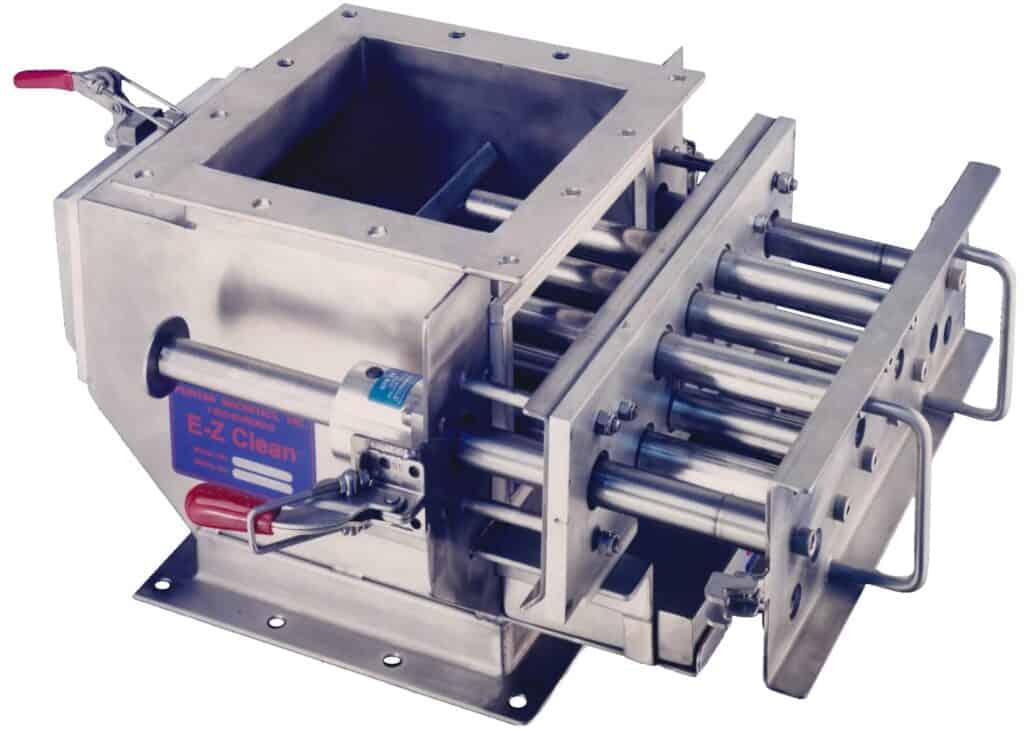

2. Drawer Magnets

Similar to the Grate Magnets used in dry, free-flowing product lines, these systems contain multiple rows of magnetic tubes in staggered arrangements for higher capture efficiency. Their modular design allows for easy cleaning and inspection. EZ Clean and POWR Clean options are also available for more simplified cleaning.

3. Plate Magnets and Chute Magnets

Mounted above or within product flow paths, these magnets attract ferrous debris as material passes over them. They are often used in powder or grain processing lines to prevent metal from reaching grinders and pulverizers. The shallower the product stream, the better the separation results will be. Heavy duty factory fabricated hinges, handle, and locking latches are provided for simple installation and maintenance. EZ Clean or POWR Clean stripper plate options are also available for more simplified cleaning.

4. Suspended Magnets and Overhead Magnets

Suspended Belt Magnets are constructed with an oversized Plate Magnet. Typically installed over conveyor belts, these powerful magnets remove tramp iron from high-volume material flows, particularly in mining and aggregate industries. As product passes under the magnet, metal contaminants are drawn out of the material to the face of the magnet. This can be supplied with a wiper arm or stripper plate to simplify cleaning. For automated continuous cleaning, a POW-R CLEAN option can be selected which incorporates a set of pulleys, belt, motor, and reducer that travels around the Suspended Belt Magnet discharging metal contaminants automatically.

5. Magnetic Drums and Pulleys

Installed at the discharge end of conveyors, these continuously remove ferrous metal from the stream and are suited for larger processing systems. Rotating Drum Magnets and Pulleys provide good separation in applications where there is a high concentration of metal contamination or terminating the product flow for cleaning of the magnet is not feasible.

6. Metal Detectors Combined with Magnetic Separators

In some applications, metal detectors work in tandem with magnetic separators to identify non-ferrous metals like stainless steel or aluminum. When detected, automatic rejection systems divert contaminated product to prevent further hazards. It is imperative that the magnet be located prior to the metal detector to reduce the number of rejections and thus loss of good product. Magnets can also capture smaller metal particles that may be missed by metal detectors.

Explosion Risk Mitigation Through Prevention

By systematically removing ferrous contaminants early in the processing line, magnetic separation equipment:

- Eliminates a primary ignition source—ferrous particles capable of creating sparks or heat;

- Protects downstream equipment from damage and associated risks;

- Reduces system downtime and maintenance due to metal-related failures;

- Enhances compliance with safety regulations such as NFPA (National Fire Protection Association) standards, OSHA requirements, and ATEX directives (in Europe).

- Protects your product from contamination.

Real-World Case: Grain Milling Facility

Consider a grain milling plant that processes several tons of wheat per day. Before installing magnetic separators, the facility would experience frequent downtime from equipment damage caused by small metal fragments, risking a fire or explosion. By implementing a series of magnetic grates and plate magnets at critical transfer points, not only would metal contamination incidents drop, but the plant could also improve its fire safety insurance rating and pass a third-party explosion risk audit without violations.

Industry Compliance and Best Practices

Industry standards increasingly mandate the use of metal detection and separation in processing lines. For example:

- NFPA 652 outlines the fundamentals of combustible dust, recommending hazard analysis and control measures such as removal of ignition sources.

- FSMA (Food Safety Modernization Act) requires food processors to implement preventive controls—including foreign material removal—for product safety.

- HACCP (Hazard Analysis and Critical Control Points) plans often identify magnetic separation as a CCP (Critical Control Point) for metal hazard mitigation.

Conclusion

Magnetic separation equipment may operate silently behind the scenes, but its impact on explosion prevention in bulk processing is both substantial and indispensable. By systematically removing metal contaminants from processing lines, these systems eliminate a critical ignition source, protect equipment, ensure regulatory compliance, and—most importantly—save lives.

As industries continue to push for safer, more efficient operations, magnetic separation technology remains a cornerstone of proactive explosion prevention strategies.

If you have a current application for any magnetic equipment or require additional assistance Puritan manufactures a complete line of magnet equipment to solve most application requirements. A wide range of standard products with E-Z Clean and POW-R Clean features are available. Custom designs are also available to solve even the most difficult applications. Additionally, Puritan provides complete engineering and product testing to assist in magnetic equipment installation decisions.

Please feel free to contact us at 1-248-628-3808 or email magnet@puritanmagnetics.com and we will be happy to assist you.

About the Author:

Andrea Webster (Inside Sales & Marketing)

Puritan Magnetics, Inc.

Ph: 248-628-3808

andrea@puritanmagnetics.com