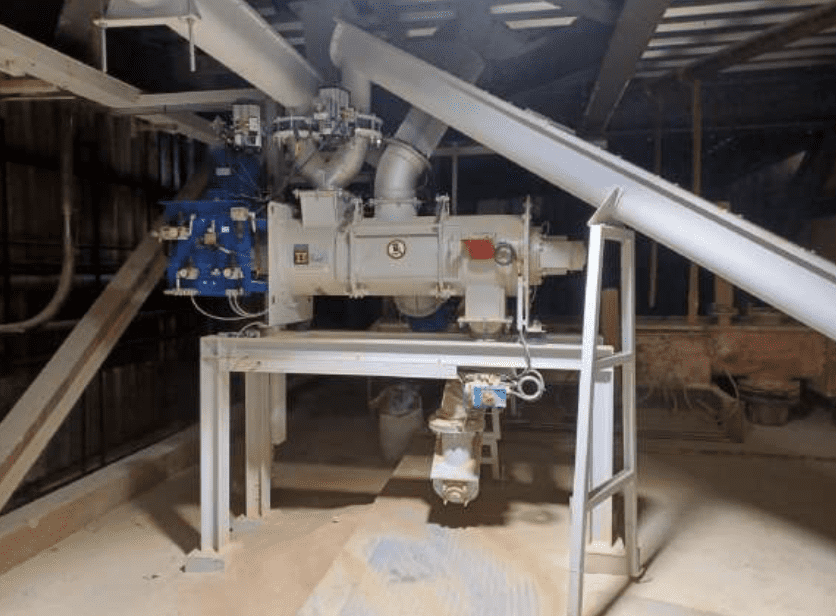

The challenge in this project was the characteristics of the materials to be dosed, mixed and homogenized, the location of the silos and the equipment in the available space.

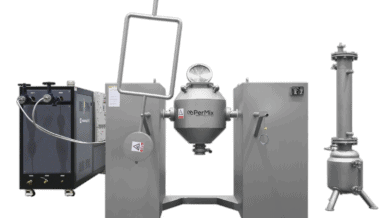

- Taking into account the apparent density for sodium sulfate of 2.66 g/cm3 and between 0.87 and 1.3 g/cm3 for the atomized products, the use of a continuous mixer of more than 200 kg/h, with a dwell time of approximately 30 seconds, a very flexible solution that allows handling recipes where the proportion of sodium sulfate can be between 10% and 70%, was proposed.

- The location of the atomized product silos, as well as their discharge, required the design of a bidirectional screw and a set of automatic valves to be able to discharge to the mixer or to the spindle of the bagging equipment as needed.

- As for the sodium sulfate, dosing was done by means of a screw from a pre-existing buffer hopper to the mixer.

- The touch-screen control is capable of interfacing with higher-level monitoring systems. The system allows for future expansion by installing a diverter valve and automatic valves.