Video

GPI Delivers Additive Line for the New Lamb Weston/Meijers Factory in Kruiningen

“Gpi is an enthusiastic club that stands for extensive knowledge and effective, enjoyable collaboration!”

Passive Explosion Protection for Mobile Dust Collection Applications

The huge range and breadth of chemicals, minerals and other materials involved in the business of contract “toll” processing led a major custom processor in the Northeastern USA to explore various Explosion Protection options with IEP Technologies with the aim of building maximum flexibility and safety into their processing plants and operations.

Selecting Magnets For Dairy Processing

The question is often asked, “Which factors should I consider and what potential problems should I be looking out for when selecting magnets for dairy processing applications?" When it comes to dairy processing, there are multiple magnetic separation options. When dealing with such a sensitive product application, it is crucial to make a well-informed decision to avoid facing unforeseen challenges and product safety issues.

Improving Spray Painting Stations with Powder Flow Monitoring

Powder spray lines are an essential component in the automotive painting process. Spray lines are automatically activated in certain time sequences.

Double Wall Modular Magnet Filter for Chocolate

The range of magnetic filters that Goudsmit Magnetics from Waalre has been manufacturing for several years has recently been expanded with a modular, double-wall chocolate filter.

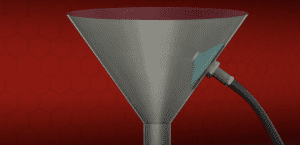

Solimar Silo Fluidizer

The Fluidizer helps to discharge dry products like cement, flour, pigments and lime. The Solimar Fluidizer uses air movement and vibration to facilitate the flow of dry bulk materials, instead of only aerating the product like fabric aerator pads.

Augmented Reality in Industrial Projects & Operations

Augmented reality (AR) is an enhanced version of the real physical world that is achieved using visual elements, sound, or other sensory stimuli delivered through digital technology. One of augmented reality’s primary goals is to highlight specific features of the physical world, increase understanding of those features, and derive smart and accessible insight that can be applied to real-world applications to help inform companies' decision-making.

Brief History of Pneumatic Tank Unloading

Although Solimar Pneumatics is best known for their Silo Fluidizer which is used in storage silos, weigh hopper and filters, Solimar got its start in aeration for dry bulk tank trailers.

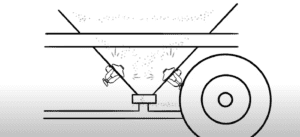

Aeration products knock clingy material out of silos with a one-two punch

Dry material clumps. It sticks. Powder, grains and even seed finds ways to cling to sidewalls and cones causing issues inside a bin or silo. BinMaster has an answer using aeration and vibration to loosen stubborn material.

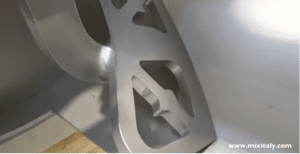

Mixer for Pasty and Medium/High Viscosity Products

The solution with a completely extractable rotor shaft on sliding support arms allows the operator easy access to every point inside the mixing chamber, allowing a complete cleaning of the mixer, the rotor shaft and the mixing tools.

This solution is optimal for use in sectors where the cleaning of the mixer with every change of recipe is of utmost importance.

Maximum Efficiency in the Smallest Room

Compact, cost-effective and quickly available - plus high-performance from capacity to weight accuracy: with the Smart Plant, Haver & Boecker serves the highly attractive development of the cement industry that’s close to the market. In the Karsdorf plant of OPTERRA Zement GmbH, the "small" complete filling and packing plant for bagged cements has been proving its huge advantages since March 2021.

Full Vacuum Dryer Mixer

The dryers are machines used to extract the moisture present in the processed material. Through the heat exchanger on the mixing chamber it is possible to heat the processed product.