The turnkey feed mill will be built on a new greenfield site in Dalton New Bridge in Yorkshire. When completed in the summer of 2023 it will be one of the most technically advanced and energy-efficient feed mills in Europe.

Initially, the new facility will produce multi-species feed (compound ruminant and poultry) on two production lines with an initial total capacity of >30 t/h – and the potential to double this capacity based on anticipated demand.

The project has been several years in the making and included reference visits by the I’Anson management team to various Ottevanger feed mills: in Luxembourg, Belgium and the Netherlands. Significantly, it will bring together several fellow sister companies within the Triott Group to deliver a single, integrated solution.

- Ottevanger Milling Engineers will manage and oversee the entire project, as well as providing most of the milling equipment.

- IVS Dosing Technology (IVS) will provide the steam dosing technology used in the conditioning process as well as the liquid dosing systems for the mixers and coaters

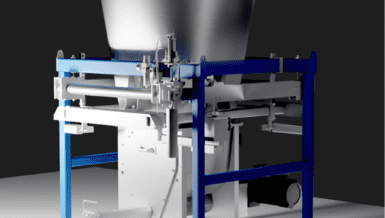

- Pellet Technology Netherlands (PTN) will deliver the innovative BOA Compactor for the ruminant pelleting line.

- Top Silo Constructions (TSC) will supply the storage solution.

- Inteqnion is providing the electrical control systems.

Said Erik Ottevanger: “This is an extremely proud day for our company – and demonstrates the importance of developing close relationships and thinking along with customers long-term. It was back in October 2013 at the I’Anson office in Masham that Chris I’Anson first laid out plans to build a new feed factory. A great deal has happened in our world since then, but this new project is a positive development in a moving market – and we are excited about what are two companies are set to achieve together.”

Chris I’Anson, Chairman of I’Anson Bros Ltd said: “Our new mill is the biggest single financial investment in the 121 year history of our company and vital in sustaining the business to meet the challenges and opportunities of the future. Choosing the right partner for this important project was critical.

“We first contacted Ottevanger in 2013 with our initial thoughts about developing a new mill that we wanted to be at the cutting edge of the feed industry. We had previously visited a number of brand new mills in the UK that they had designed and built and had been impressed by the quality of the design and the machinery.

“Since then we have visited many of their similar installations around Europe and seen the same high quality of work at each site and this gave us the confidence that they were our ideal project partner.

“Both our companies are fourth generation family businesses with a deep understanding and experience of what our customers require and this has helped both of us in developing the ideas and design of the new mill which will put I’Anson at the forefront of our industry.”